Slide 3

This page was tagged as a candidate for deletion. If this page does not meet our criteria for deletion, please remove this notice.

(Explanation: contents moved to Slide 1)

Slide 1 - Slide 2 - Slide 3 - Slide 4 - Slide 5 - Slide 6 - Slide 7 - Slide 8 - Slide 9 - Slide 10 - Slide 11 - Slide 12 - Slide 13 - Slide 14 - Slide 15 - Slide 16 - Slide 17 - Slide 18 - Slide 19 - Slide 20 - Slide 21 - Slide 22 - Slide 23 - Slide 24 - Slide 25 - Slide 26 - Slide 27 - Slide 28 - Slide 29 - Slide 30 - Slide 31 - Slide 32 - Slide 33

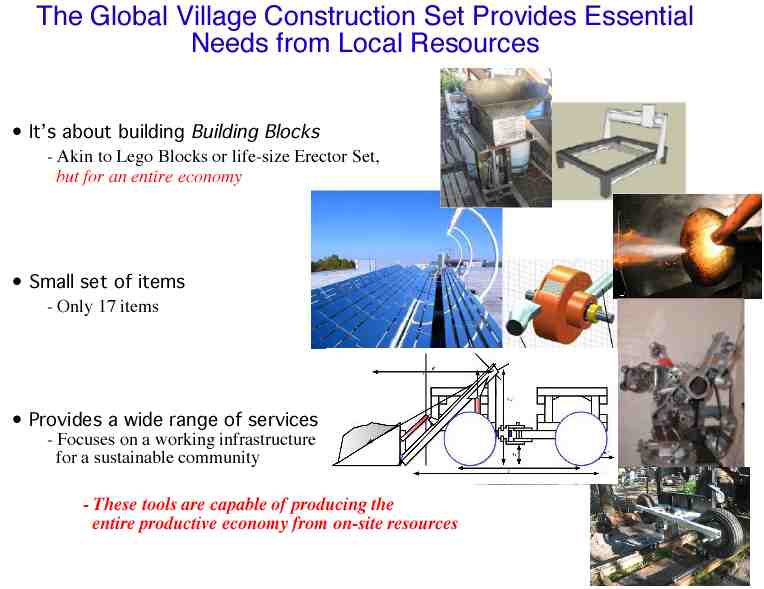

What are these tools? If we talk about living sustainably, we need to start with essentials. Housing. Energy. Food. Fuel. Technology. Everybody uses these. Might as well get these right. There is no shortage of markets if these succeed. Better make these low cost, durable, simple, efficient technologies. Then we can live dirt cheap and spend our time on other things than making a living.

Consider housing. The Compressed Earth Block (CEB) press and a sawmill could get you the building materials – bricks and lumber – for building your habitat. If you’ve got a CEB press and sawmill – plus land for soil and trees – you can build an entire village with little cost. A good home should not be the end of your American dream – it should be free. No-one in history long gone, or nature, pays for their housing. Let’s take that as a good model..

Consider energy. Take solar concentrators, proven technology, with backup multifuel burner, and heat storage cistern from CEB blocks – all powering the Solar Turbine.

Consider the tractor. Articulated, multipurpose ag-construction, with PTO for sawmill, hydraulics to power your CEB press, rototiller for ag and CEB soil prep, front end-loader and backhoe for all purposes. Stewarding the land – agriculture, building, forestry, ponds, berms, and industrial power are possible with this.

Consider fabrication machinery. Open Source multimachine – a mill, drill, lathe – fittable with other attachments to make it into a table saw, cutoff saw, metal saw, grinding disk, pipe threader, and so on. All types of machining from 1 machine, starting at $300 for a basic machine – built from discarded engine blocks which provide the necessary precision. Add computer control using widely available techniques - and you are talking about the backbone of digital fabrication.