Sawmill: Difference between revisions

Negligiblek (talk | contribs) No edit summary |

|||

| Line 25: | Line 25: | ||

=Sawmill - Design Calculations= | =Sawmill - Design Calculations= | ||

[[Sawmill - Design Calculations]] | |||

=Sawmill - Current Work= | =Sawmill - Current Work= | ||

Revision as of 01:02, 29 May 2009

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

Please answer any questions on the Sawmill_Questions page if you can. Thank you!

A sawmill enables custom lumber production on site using locally available timber. An easily replicable lumber mill creates real value for the producer at a low cost of entry, a necessity for self sustaining community decentralized economy. Decentralized sawmilling may obviate clear-cut lumber companies in a new economy. Wood construction is one of the earliest methods of building shelter. Current lumber production is highly concentrated industry save the specialty wood shops producing for novelty wood workers. Unsound harvesting practices and high transportation costs make commercial lumber environmentally costly. Timber can be locally harvested and with a simply designed, low cost sawmill we can produce fine quality lumber sustainably and economicaly.

Product Definition

Sawmill Design Rationale

Sawmill Research

Sawmill Design developments

See Sawmill Design Developments

Sawmill - Design Calculations

Sawmill - Current Work

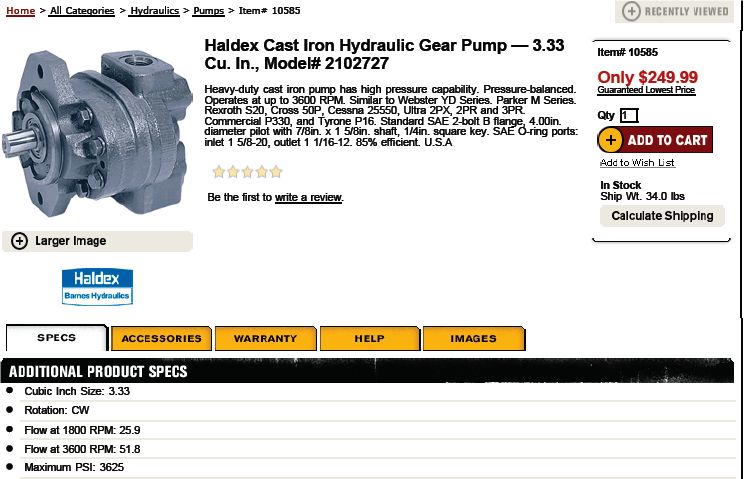

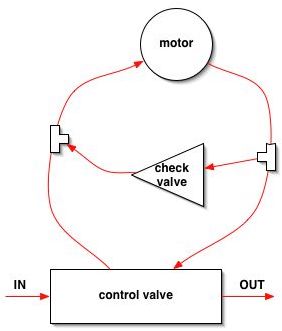

We have a hydraulically-driven PTO motor as a start. It will be powered by LifeTrac. LifeTrac has this pump from Northerntool - [1]:

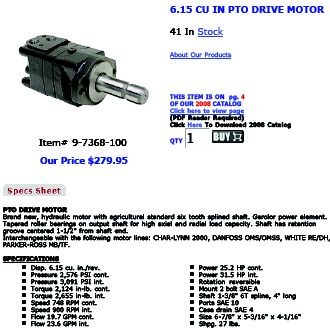

All hoses are already available - it is part of our flexible open source tractor infrastructure. Here are the motor specifications, from Surpluscenter.com:

Here is the hookup diagram:

Note: Since we have 3600 PSI available, we can run 2 of these motors in series to match available power more closely.

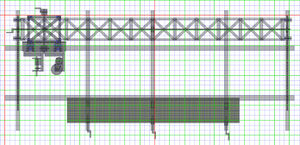

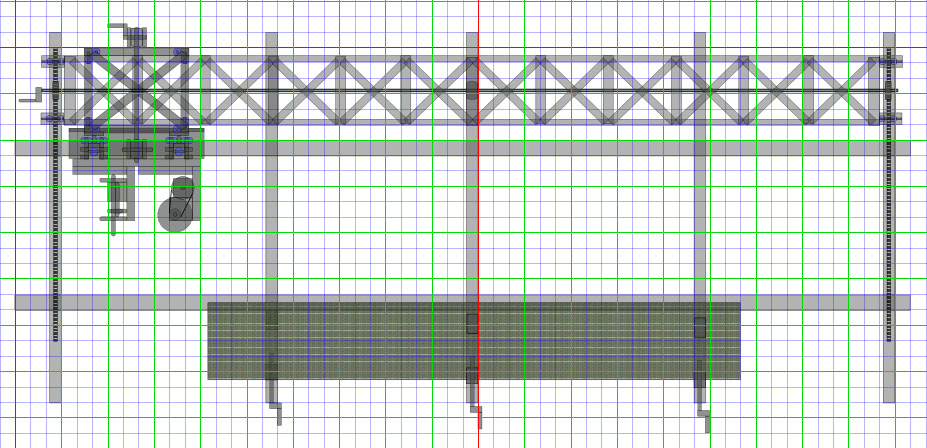

A very preliminary prototype drawing, top view:

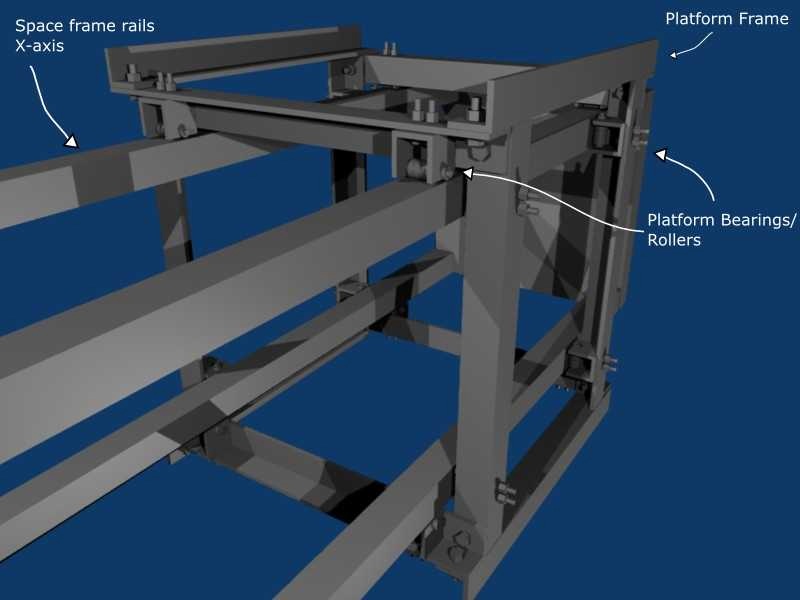

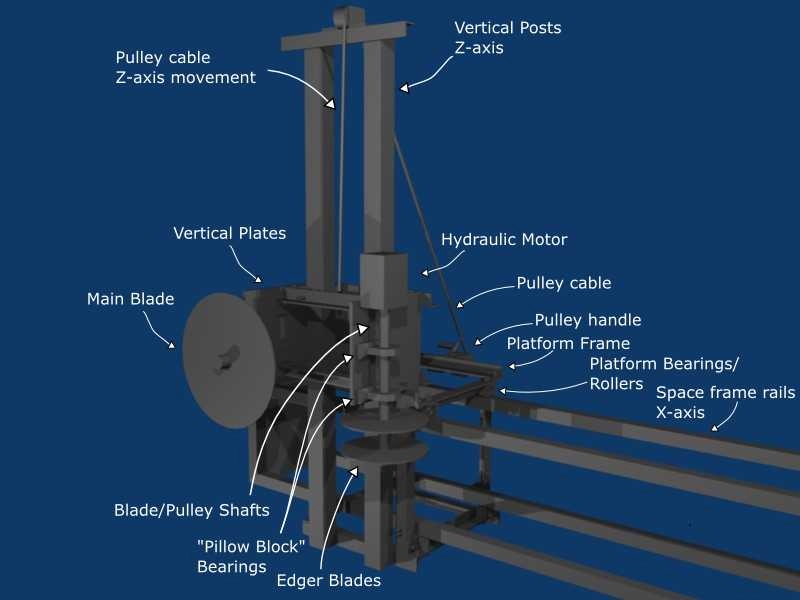

3D CAD - Using Blender

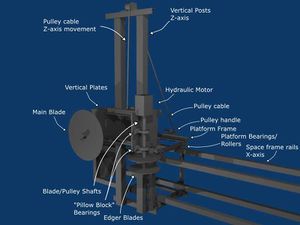

Preliminary 3d pictures of the sawmill:

Sawmill Deployment

Implementation

Design

- With design rationale, put it up for review on Red Pages

- Finish design in 3d, go through cutting process

- Get feedback on design, post on sawmilling forums

- Iterate design and feedback until design is finalised

- Make bill of materials for final design

Test Construction

- Build space frame and platform frame as a first test, to test x axis motion

- Test x axis motion

Construction

- Purchase one blade, 30", 2 blades, 12"

- Build cutting head - gear up the blade

- Install all safety devices before operating

- Test sawmill operation without blades attached

Bill of Materials

Collaboration

Current Steps

See Sawmill_Project_Status for detailed current status and past history actions.

Current Stage:

Developments Needed

Documentation and Education

section unfinished (this section is dedicated to preparing and disseminating results, in the form of publications and technical reports.)

Documentation

Sawmill Prototypes

Education

Collaborators Sign-Up List

If you'd like to collaborate on this project please email the Project Lead listed below with the following

Subject: Name, email, and Skype are preferable.

Listed below are the collaborators on this project

- Temporary Project Lead - {Need Name of Lead} project lead's email dot com, phone xxx.

List of Prototyping Collaborators with Access to Fabrication Capacity

Resource Development

List of Stakeholders

(this is a list and description of individuals, groups, organizations, and institutions that may be particularly interested in the product under development, at any of these levels:

List of Supporting References

Internal Links to Diagrams, Flowcharts, 3D Computer Models

(Please create new pages, embed Category:Sawmill in them, and then place a link below to your new page).

Diagrams

Diagrams with Basic Ideas

Basic Calculations

Flow Charts

Pattern Language

Publicity Sites Listing and Possible Collaborators

Funding

Pre-Ordering Working Products

If you're interested in buying our product before it has been completed in order to speed our project, please contact:

Project Lead listed above

with the Subject line as follows:

Subject: Sawmill Pre-Order: Name and Skype are preferable.

User/Fabricator Training and Accreditation

User Training will be provide to those who Pre-Order our Sawmill.

Fabricator Training will also be available upon completion of this Project.

External Links to Standards and Certification Development

The Industry Standard this Project hopes to meet:

- Independent review will be solicited as a means to verify and control quality of products and services.

Volunteer Grant Writers Sign-Up List

If you'd like to grant write for us on a volunteer basis for this specific project, please contact:

Project Lead listed above

with the Subject line as follows:

Subject: Volunteer Grant Writer: Name and Skype are preferable.

Professional Grant Writers Sign-Up Lists

Outcome-based only.

If you'd like to grant write for us on a professional basis for this specific project, please contact:

Project Lead listed above

with the Subject line as follows:

Subject: Pro Grant Writer: Name and Skype are preferable.

Collaborative Stakeholder Funding Sign-up List

Name, email, and Skype are preferable.

(Once products are demonstrated, we will solicit stakeholders to fund production capacity. This is a highly innovative social enterprise model, where stakeholders contribute a small amount, say $50, to the actual building of a facility for producing a specific item under the model of flexible fabrication. This is essentially a question of distributing the development and production cost via a collaborative enterprise model.)