D3D v20.04

Jump to navigation

Jump to search

| Description | Link to Work Product | % | |

|---|---|---|---|

| DESIGN | |||

| 1 | Requirements + Value Proposition | [[{{{0}}} Requirements + Value Proposition]] | D3D_v20.04 |

| 2 | Industry_Standards | [[{{{0}}} Industry Standards]] | {{{2}}} |

| 3 | Conceptual Design | [[{{{0}}} Conceptual Design]] | {{{3}}} |

| 4 | Module Breakdown | [[{{{0}}} Module Breakdown]] | {{{4}}} |

| 5 | 3D CAD | [[{{{0}}} 3D CAD]] | {{{5}}} |

| 6 | Calculations | [[{{{0}}} Calculations]] | {{{6}}} |

| 7 | Electronics Design | [[{{{0}}} Electronics Design]] | {{{7}}} |

| 8 | Wiring and Plumbing | [[{{{0}}} Wiring and Plumbing]] | {{{8}}} |

| 9 | Software | [[{{{0}}} Software]] | {{{9}}} |

| BILL OF MATERIALS | |||

| 10 | BOM | [[{{{0}}} BOM]] | {{{10}}} |

| 11 | vBOM | [[{{{0}}} vBOM]] | {{{11}}} |

| 12 | CAM Files | [[{{{0}}} CAM Files]] | {{{12}}} |

| 13 | Cut List | [[{{{0}}} Cut List]] | {{{13}}} |

| BUILD | |||

| 14 | Build Instructions | [[{{{0}}} Build Instructions]] | {{{14}}} |

| 15 | Fabrication Drawings | [[{{{0}}} Fabrication Drawings]] | {{{15}}} |

| 16 | Exploded Part Diagram | [[{{{0}}} Exploded Part Diagram]] | {{{16}}} |

| 17 | Production Engineering | [[{{{0}}} Production Engineering]] | {{{17}}} |

| DATA COLLECTION | |||

| 18 | Build Pictures and Video | [[{{{0}}} Build Pictures and Video]] | {{{18}}} |

| 19 | Data Collection | [[{{{0}}} Data Collection]] | {{{19}}} |

| 20 | Future Work | [[{{{0}}} Future Work]] | {{{20}}} |

Specifications

- 12" heat bed

- 1400W heat bed

- Transitioning to OSE Universal Gearless Extruder

- Based on D3D Pro geometry

Working Doc

Part Library

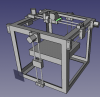

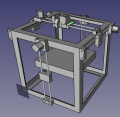

D3D v2004 Assembly - FreeCAD -File:D3d v2004.fcstd

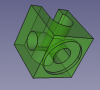

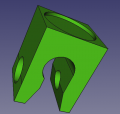

Auto parallel piece. File: File:Autoparallel.fcstd File:Autoparallel.stl

Cut List

Using 3D Printer Workbench 2020:

- X - [2] 22”

- Y - [4] 21”

- Z, bed, spool holder - [9] 17”

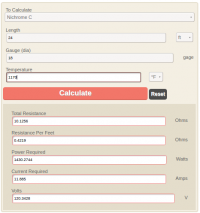

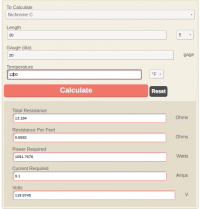

Heater Element

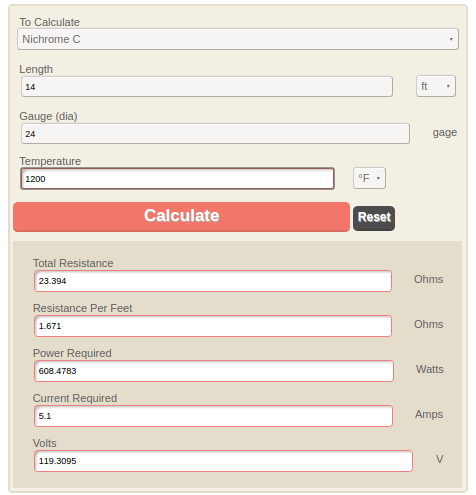

(See Nichrome Calculator)

Notes:

- Fiberglass sleeve used - HTG fiberglass, does not fray like standard high temperature sleeving (1000F) and is rated for . See [1]. Note that the resin can burn out at the 650C (1200F) workign temp. Sleeve has VW-1 flame resistance. Made of fiberglass, it does not burn out, but may fuse and lose fiber structure.

- Inner core: 5' long wraparound of 2mm tight braid fiberglass sleeve - 600C - [2]. Started with 5', wrap was more like 4' long.

- This is packed into 4' of 6 mm tight braid fiberglass sleeve.

- Fence wire is used to couple 200C wire to nichrome, in order not to burn out 200C wire. Nichrome is wrapped around the fence wire 5-10 turns

- Copper wire is soldered to the fence wire.

- 10" end piece of 6 mm tight braid sleeve covers the 200C wire, fence wire, and ends of nichrome.

- 2 strands of nichrome heater element are made, each 14' long, each about 600W.

- Ends, covered by 6 mm tight braid sleeve - stick out the finished bed. Third wire set is the thermistor, which is wrapped with 2 mm tight braid so it doesn't melt out.

Heater Optimization

Theoretical idea:

But, ga 18 can't bend easily using a cordless drill.

- 20 feet of 20 ga wire appears to be most convenient - 1 piece, max at 1200F. Current 500W heater is 1200F max, and works well.

- 14 feet of 24 ga works perfectly by hand to get a good wrap over 4 feet, and goes fast, about 1 minute pending tieups:

Heater Element Wrapping Procedure

- Cut 14' of ga 24 nichrome

- Cut 5' of tight 2 mm fiberglass sleeve

- start the wrap of nichrome on one end of sleeve

- Attach other end of sleeve to a free-spinning rotor

- Once enough to go inside a cordless drill chuck - grab the nichrome wrap and turn on the drill in reverse to start wrapping. Tension the sleeve against the rotor

- Wrap away! A person should be able to wrap 4 feet long just by holding a cordless drill