Jeremy Log

Wiki Cheatsheet - Jeremy | Jeremy Log Supplemental

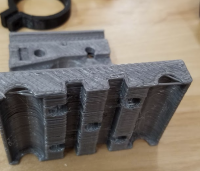

![]() Hint: Are you distilling best PPE to make? Let me know your progress - once I have the filament maker going, I plan on printing 24/7 with essentially free feedstock. -MJ

Hint: Are you distilling best PPE to make? Let me know your progress - once I have the filament maker going, I plan on printing 24/7 with essentially free feedstock. -MJ

Time Log

March 2020

ToDo

- Create v2 of pricing calc sheet

- Finish D3D Pro Hardware assembly

- Coffee with Mary for OSE - BMS collaboration and contact sharing

- Work out instructor coverage for April 25 to May 3 Camp

Someday/Maybe

Mon Mar 23:

Covid Mask Research and brief messages with Chris. Have many requests from local hospitals and nursing homes for masks, face shields and other ppe.

Fri Mar 20:

Weekly Call, Covid-19 thoughts and research.

Wed Mar 18:

Speculation on reuse of n95 masks: Can you heat treat the masks at 145 degrees for 30 minutes and then reuse them??? In milk production, 145F for 30 minutes basically kills everything. I don't know the heat tolerance of the mask materials, but 150F is not all that hot?

Tue Mar 17:

GcodePlot Install Instructions, milling toolchain research for KiCAD -> .gcode

Mon Mar 16:

File:Plottergcodesample-jeremy.ini, g-code plot install for Jessica, Work on Fablet case and File:BoardRiser1.fcstd File:BoardRiser2.fcstd, pi Fablet wiring and instructions Photos, Pi Fablet Working doc updates Slides 2 - 5

Sat Mar 14:

File:Jeremyplot+drill.ini, updated D3D Universal Build Manual- Reorganized slides to fit with index list, Added Drill and plot basic over view and curriculum Slides 4 to 16.

Fri Mar 13:

Packed tools, parts etc. Notified around 5pm that Adrian cannot make it. Cancelled our event at BMS.

Thur Mar 12:

Checked parts and repacked kits. Packing up tools and other items. Continue to print off parts for BMS printer.

Wed Mar 11:

Make backup plan for parts for BMS. Print control panel and rest of parts for D3D U. Emails. Moved Curriculum March 2020 STEAM Camp to OSE March STEAM Camp Curriculum - Working Doc. Updated PiFablet USB wiring plan and posted photo.

Tue Mar 10:

Plotting and drilling all afternoon. Photos of plotting and drilling. Fine point marker leaving large lines, will try ultra fine. Current Plan: Draw traces and pads with ultra fine tip, change offset and mill out holes. (Perhaps try Pica Brand Marking Tools expensive but altrafine, and grease pencil may be optimal for etchant protection? - User: Eric)

Mon Mar 09:

Emails and planning for upcoming events. Review Plotter and mill Curriculum - Collated links and learnings at STEAM_Camp_9_Day_Curriculum. Modified File:RouterToolhead.FCStd with additional pen holder, hoping to plot and then drill without tool change (was suggested by Belgium group I think?). Working price quote for shredder teeth.

Plot and Drill Plan: Use combined plotter/mill File:RouterToolhead.FCStd. Export gcode from Inkscape and open for manually editing. Edit:

;load gcode file into CURA - for access to gcode command-line during pauses M0; Pause after 0,0 for inserting pen ;move z zero up to avoid hitting mill bit on work surface - ;G00 F300.0 Z4.000; z down ;Insert pen then zero z here G92 Z0 ;z- set 4.00 to now be 0 to keep drill out of work area. G00 F300.0 Z5.000; pen up !!Zup G00 F300.0 Z0.000; pen down !!Zwork G00 F300.0 Z5.000; pen up !!Zup G00 F300.0 Z0.000; pen down !!Zwork G00 F300.0 Z5.000; pen up !!Zup M0 ;pause - verify correct marks at home zero - will use these to adjust offset of mill bit later. Do plotting gcode ;At end of file - back to x0,y0 G00 F2400.0 Y0.000; !!Ybottom G00 F2400.0 X0.000; !!Xleft G00 F300.0 Z20.000; pen up !! M0; Pause - remove/lift pen and add or adjust height of mill be sure NOT TO BUMP the bed. ;line up drill manually ;manually drill the alignment hole very slowly G92 Z0 ;set z zero once hole is sufficiently deep ;commence drilling - insert hole punching gcode following ;suggest drilling code have a higher z clearance - more vertical movement between x y moves ;the goal is to use one gcode file to plot all the traces, then adjust the xy zero so that the drill can hit the correct positions. Not removing the PCB during this operation should assure everything is aligned correctly. ;TODO-determine the X Y offset between pen and drill on a test plot of wood/cardboard, hard code into gcode file with pauses for verify and power up drill.

Save the file then load in CURA - Activate control window - M0 Pauses allow stops/resumes and injection of manual gcode via cmd line via CURA. (also get nice progress bar to help pass the waiting)

Sat Mar 07:

Bellingham Makerspace Meeting, D3D Pro Build Jeremy D3D Pro Current State, 120V Heater Coil Wrapping Process, STEAM Camp Emails

Fri Mar 06:

Weekly STEAM Call, D3D Pro Build.

Thur Mar 05:

google docified steam camp marketing page. USB Testing and research for Pi Power Packs [1], research heating profiles with latest pi firmware.

Wed Mar 04:

Slack -> Scrum integrations Browsing. Scrumy.com is back online, and should have an updated version in next month. Minor updates on several STEAM camp marketing pages. Phone call with Bellingham makerspace - Jason (our liaison).

Tue Mar 03:

Great phone call with Friday Harbor High School and Samuel_Garson. Mailchimp mailer finalized, verified and sent, STEAM Camp FinancesWorkshop price calculator/visualize, Brief discussion with principle at LC Middle School.

Embed Editable Google Doc + add "&rm=minimal" to the query string to remove tool bars and login info.

Mon Mar 02:

Changed TOC CSS for Jeremy Log. Canvas for more CTE email addresses in local area. Prepare MailChimp(freeversion) mailer for Tuesday. Phone call with Bellingham Makerspace re:hosting March workshop.

February 2020

February 29, 2020:

PiFablet Meeting, PiFablet Screen Testing

February 28, 2020:

Instructor call, Marketing emails, posted list of addresses and email templates

February 27, 2020:

Met with Lynden Christian School CTE Leadership to discuss camps/3d printers in classes. Email - Friday Harbor High School CTE re:3d printer workshops.

Email Assistance League of Bellingham [2]- Local summer program assistance fund, OSE workshops qualify for their funding (up to $900)... suspect other assistance groups around the country offer similar programs. Assistance League National Page

February 24, 2020:

Met at ReSources to put down $ for rental space for March workshop. This space is great and very reasonably priced + the ReStore is just awesome! Posted some flyers around town and pitched some influencers I had meetings with today.

Printed full Pi Front Bezel [3].

February 22, 2020:

D3D Pro axis, parts cleanup[4], 4 x 18650 battery holder w/ magnetic lid[5](FreeCAD learning and teaching to a friend). RAMPS 24v conversion on new board.

February 21, 2020:

Backup venue secured, returned completed contract Re-Sources.org. Planned visit to site Monday to assess. Posters printed for around town. FB[6] and LinkedIn[7] posts. FB Event [8] Reached out to 40 local career councilors, local politicians, friends and teachers asking for support and marketing.

February 20, 2020:

Marketing Emails and FB posts for March 14 to 17 camp

February 19, 2020:

D3D Pro bed modifications. Instructor planning call. Followup with venues... trying to secure a backup location.

February 18, 2020:

Continued call and emailed for a Bellingham/Seattle Venue - All day.

Finally heard back from Bellingham Makerspace at EOD, I think this is our location... waiting for 100% confirmation...

February 17, 2020:

Called and emailed for a Bellingham/Seattle Venue - All day.

February 16, 2020:

Compiled list of local career councilor email addresses. Spent time looking for a venue for the upcoming class. Contacted several local teachers I know re:workshop. Prepared emails scripts for sending once venue secured. Joined several Facebook groups where I can publicize the workshop. Started process of renewing my WWU system credentials to post events in WWU bulletin board system. Posted event in [WhatcomTalk page]. Looked up several "influencers" on Youtube, planning to ask them to plug us in the next week or two (we could even send them a kit and ask for a review!). Emailed two addresses associated with Adam Savage (wouldn't it be great if he started plugging for OSE).

Consulted friend who manages online marketing, for some very large companies, in regards to best strategies for drumming up workshop participants.

- If we have paid budget use it on FB or Twitter. If the event is in Bellingham, do a geo targeting around the area as I would assume most people that can fly would attend the other in person events as they seem to be larger. You should also look into LinkedIn.

- For free stuff, look to join groups and post mercilessly. Groups would be on Facebook and LinkedIn.

- In a general sense, see if you can find "influencers" in this area and ask if they would be willing to help promote. So look for people on YouTube, Twitter, Facebook, LinkedIn, etc who have larger or engaged audiences who focus on this kind of stuff and send them a note. It never hurts to ask!

- Lastly, going to high schools and colleges is not a bad idea at all. Specifically schools with technical clubs or programs. "

He offered to help out with our marketing in his spare time if he can have a printer... I offered to order everything at cost and help build. I think he'll help us out once his super busy next couple months blow by. Finally, I asked him to come to a workshop as a documenter, to get a feel for it and help with capturing what we do for instructionals and future marketing.

D3D-U Extruder jamb for second time today... think its the retract settings, but not really sure.

Pi Photo Gallery

- Great Link for embedding google photos galleries

February 15, 2020:

Instructor Material Review, Latest Instructor Call, D3D Pro 12" Bed Build Start

February 14, 2020:

Instructor Video2 + WL Part Library:

Test 1 - FreeCAD -File:JeremyTest5.fcstd

Test1 Merge - FreeCAD -File:JeremyTestMerge6.fcstd

February 13, 2020:

PiFablet Parts Library Updates, PiFablet Parts Merge, PiFablet Rear Cover, PiFablet Photo Archive

Updates and Edits on PiFablet Design Doc.

February 12, 2020:

Instructor Video first try + WL Part Library:

Continued to print off parts for D3D Pro. Worked on PiCase [9] Bezel is 90% complete... tested a partial print for fit.

February 11, 2020:

Modified Angle Corners with Fillet on interior corner to allow angle iron with radius interior corners. Right Corner Left Corner Angleconnector Cut, grind and paint 12 pieces of angle iron for D3D Pro build. [10]

February 10, 2020:

Printed off several more angle corners. Having issues with fit of angle iron - Printed parts with 1.2 nozzle and similiar Cura settings to the .ini files Marcin provided on the d3d parts catalog. Fit is too tight, using heat gun to give some room, may need to reprint the bottom corners.

February 9, 2020:

Quick updated to D3D-U BOM sources for loom.

12 inch heated bed FreeCAD added to 120V Heated Bed page.

Started printing Angled Corners for D3D Pro. Learned a bit about removing scaffold and bed adhesion on D3D-U - Good adhesion printing directly onto buildtak on steel plate (preheat steel plate with heater, brim =5. Had to put plate in freezer to get release as large hammer and all the scrapers not effective. Spring steel plate adhesion great, so much so that plate warps = parts warped.

These 2 files are cut plans for 12 Inch 120V Heated Bed. File:Dxf12inheatedbedtop.dxf File:Dxf12inheatedbedbottom.dxf

February 8, 2020:

D3D Pro Parts Ordering and Research. Planning to put together in the next few weeks. Ordering components from aliexpress, planning to pull parts from universal if they don't arrive in time. Walked thru wiring, current instructions, crossreference for D3D-U to D3D Pro to D3D 19.06 and hopefully have a complete list of what we need to order, print, and what we can steal from the D3D-U that we have on site.

Started printing corner brackets.

Reworked CAD for Fablet case. Hope to have something to post and print tomorrow.

February 7, 2020:

Work on Pi tablet design and assembly concept mockup. See Parts Library [11] or design Google Doc. These need to be redrawn to fit/scale exactly with Pi and screen. This served as a quick way to visualize how to print this in layers, hopefully will help others as well. The bezel needs to have screen mounting loops inset. Hoping to hold the entire case together with 6 or 8 screws externally.

Camera??? Also, where/how do we put the camera on? I thought it would nice to have it on a pivot/hinge at the "top", so it can be used for conferencing and as a hand held camera easily? Pivot up over the "top" to point at the user, pivot back and tuck into back side of screen for hand held camera mode. Need to come up with a printable hinge that a ribbon cable can run through.

February 4, 2020:

More work on bezel + test print for fit.

February 3, 2020:

https://www.jeffgeerling.com/blog/2019/raspberry-pi-4-might-not-need-fan-anymore

Drafted a bezel for testing screen fit. Updated size and fit for Piholder piece. Did some test prints for fit and alignment as initial draft did not account for pin height under the board.

February 2, 2020:

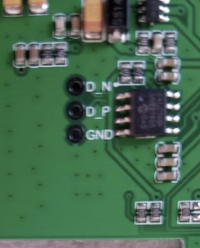

Power and USB alternate input to display on Pi Fablet attempted and verified. New Minor Problem: When Pi is shutdown from OS, Pin 4 still have 5v, so screen stays on until USB is powered off or disconnected. [Possible Work Around]

Uploaded a CAD mock-up for PiCase with notches/inset rear slots so that the important connectors can be accessed on the Pi. Mock-up includes an area for the forth coming OSE battery pack. Notes/thoughts in dev working document.

February 1, 2020:

Worked on Pi Power issues. Discovered that screen (powered from Pi via USB) and Pi (powered from wall) would not load or power up. If they are each powered from a wall adapter, they boot normally. Tried using power from the 5v (pin 4)on the GPIO rail to run screen. Made USB cable (only power wires) to 2 pin connector (stole connector off old GPU fan). Routed this to pins 4 and 6. Both Pi and screen boot up right away. This seems the only way to power the screen from the Pi and reduce the incoming power cables from wall to case to 1.

NOTE: The USB cannot power the screen during BOOT, but was able to power the screen if the USB to screen was switched to Pi after BOOT.

Could also use a battery pack like [Battery Bank] and leave the charging port exposed and then use normal USB wires inside the case to power screen and Pi. Might be possible to modify Pi boot up to keep the USB off until OS is loaded, would not rely on a hardware hack to complete.

TL;DR: Found workaround for power issues, will reduce case size as well.

- TODO: Explore sending power directly from GPIO pin 4 to the 5v solder pad/test point on back of screen. This could eliminate all need for a USB power Line.

- TODO: Explore/Test USB solder pad to USB connector, may provide touch screen interface and power without using any USB ports on PI, making it easy to leave them at the edge of case and accessible. (this would require soldering these lines directly to the underside of the PiBoard on the correct pins, and may be a more involved solution than we are looking for, but still worth investigating)

Installed raspbian OS. Had some issues getting correct resolution on display. Manually set resolution in /boot/config.txt to 1088 x 600 (its 600x something odd... don't remember exactly). Very odd, but the stated native resolution left back side bars.

Printed of "L" carriage bracket for z-axis on D3D-U. The initial bracket not square. Planning to try to straighten, but wanted spare on hand.

Ran multi-meter on solder pads(factory test locations?) on back of Pi display we have been working on. Confirmed that labels on board correspond to the correct pins on the USB circuit.

January 2020

January 31, 2020:

Reviewed Pi wiring and layout on bench. Researched Pi pinout. [12]

Pi placeholder CAD parts for helping to determine optimal part assembly to minimize form factor of table. Pi Part Library Screen, PiHolder.

Made a couple fun replacement parts for an RC car that has been broken on my bench for a couple weeks. Fun exercise in free CAD.

January 30, 2020:

Morning:

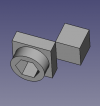

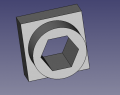

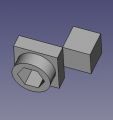

Worked on PiBase CAD. Not likely to be useful as some of the ports will be needed internally, but a good excercise in fully constrained drawings. ![]()

Researched Pi specs and screen interfaces and cabling.

Afternoon: Ran g-code generation in inkscape and sent to D3D. Printed updated fan/pen/prox holder for install at later date.

January 29, 2020:

Power Experiment Links: SlideDeck 1[13], wiki batterypack page[14], PowerPanel Wiki[15], Term. Block[16], Electrod Holder[17], Light Dimmer Slides [18] [19]

D3D Issue-O-Day:

Started printing plotter attachment and y-axis movement issues. Spend to long on troubleshoot. Ended up tweaking alignment of rails, and tracking down idler bearing not spinning freely. Also learned that the nozzle heat break fan is really good for ruining adhesion on the side of the bed its aimed at. Thinking future versions should move the air upwards, or possibly turn the fan off for the first few layers. Can we find a passive cooling solution?

Experiencing slight nozzle drag on nozzle moves. Is this an axis alignment issue, carriage free movement, or steps/mm? Read up on OS install to Pi, played with Pi parts like giant Legos... how best to fit together to achieve thin form factor.

January 28, 2020:

Researching wiki for current CNC mill progress, looking for previous CAD that is usable to attach to D3D-U. Found firmware info and spindle mount and Full working prototype from earlier D3D

Good Videos for FreeCad: Slicing parts from assemblies that are already created and have had their layers "flattened". FreeCad 0.18 PART WB using SLICE and SLICE APART FreeCAD of a simple screwdriver - drawn and printed.

Reviewed Arduino homemade documents and photos from Texas.

January 27, 2020:

Reviewed Wiki usage documents etc. Ran calibration prints and temp calibration print in D3D-U. Youtube tutorials on inkscape -> gcode. Pushed fresh install of mediawiki to sandbox server for learning purposes.

Sunday January 26:

Baby Step Calibration Procedure. D3D Universal Build Manual Calibration of D3D universal- Local. First Prints on FB Page