Steam Engine Design: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| (5 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{ToolTemplate | ToolName=Steam Engine}} | |||

{{Category=Steam Engine}} | {{Category=Steam Engine}} | ||

| Line 16: | Line 17: | ||

** [[Steam Engine Design/Boiler]] | ** [[Steam Engine Design/Boiler]] | ||

See [[Steam Engine Reviews]] for design criticism and [[Steam Engine Design/Suggestions]]. | |||

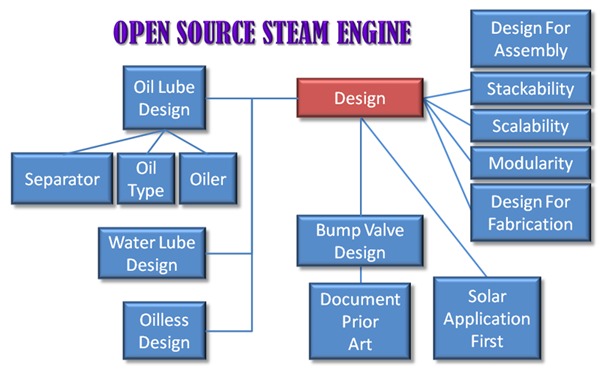

[[File:Design-Chart.png]] | [[File:Design-Chart.png]] | ||

| Line 31: | Line 33: | ||

* 5/11/11 - Rev. 5: Added mount brackets, pillow block, extended piston stem. | * 5/11/11 - Rev. 5: Added mount brackets, pillow block, extended piston stem. | ||

* 5/25/11 - Rev. 6: Widened cylinder flanges, dropped water vent, added sensor vent, cylinder liner to scale. | * 5/25/11 - Rev. 6: Widened cylinder flanges, dropped water vent, added sensor vent, cylinder liner to scale. | ||

* 7/20/11 - Rev. 7: Merged valve cover and mounting bracket. Added oiler. | |||

==1. Steam Fires== | ==1. Steam Fires== | ||

[[File:Design- | [[File:Design-7-A.png]] | ||

==2. Steam Expands== | ==2. Steam Expands== | ||

[[File:Design- | [[File:Design-7-B.png]] | ||

==3. Steam Vents== | ==3. Steam Vents== | ||

[[File:Design- | [[File:Design-7-C.png]] | ||

==Description== | ==Description== | ||

| Line 71: | Line 74: | ||

* [[Steam Engine Design/Piston Valve]] | * [[Steam Engine Design/Piston Valve]] | ||

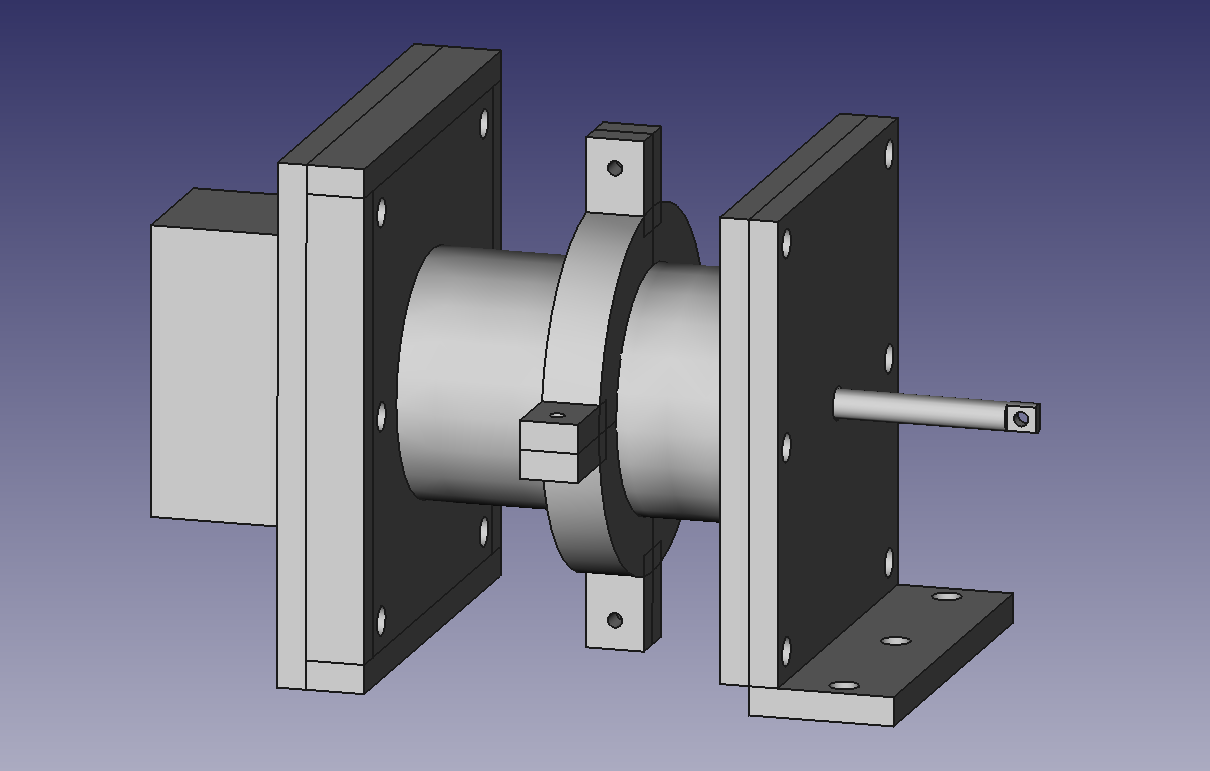

=CAD View= | |||

[[Image:Steam_Engine_CAD_Render.png]] | |||

Latest revision as of 02:20, 21 July 2011

| Steam Engine | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Main > Energy > Steam Engine

This page will be used to describe the OSE Open Source Steam Engine design, design issues, and completed drawings.

See bump valve prior art - http://www.rossen.ch/solar/wcengine.html

See also:

- Existing and Historic Designs

- Other Engine Designs

- Steam Generator Designs

See Steam Engine Reviews for design criticism and Steam Engine Design/Suggestions.

Bump Valve Engine Design

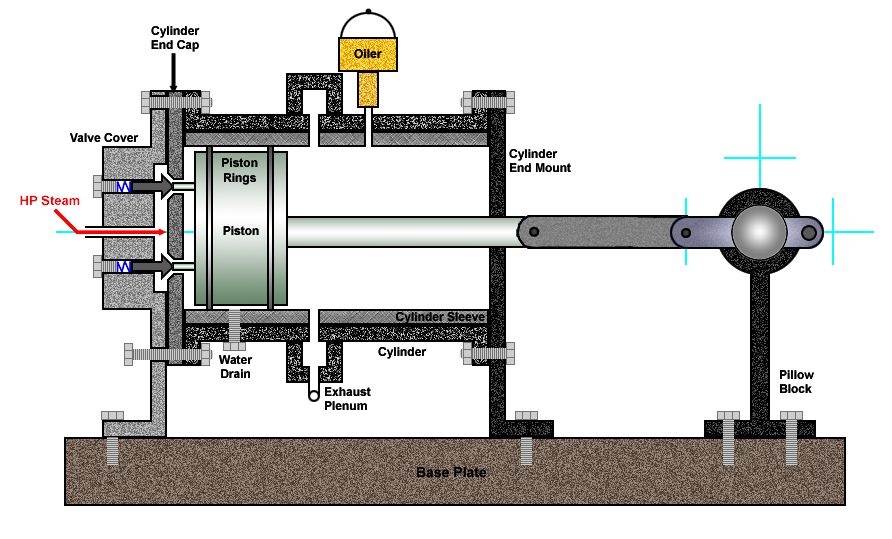

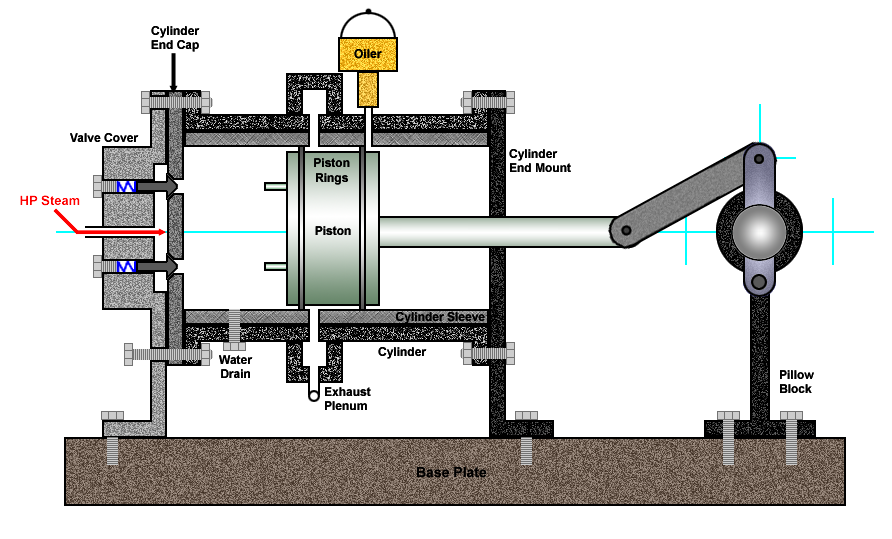

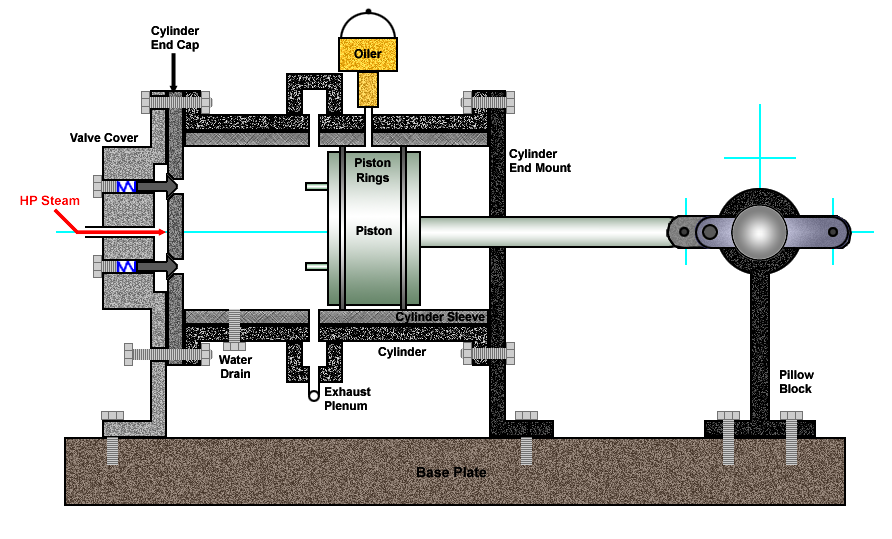

Three points in the steam cycle are shown.

Design Updates:

- 5/2/11 - Rev. 2: Initial bump valve design.

- 5/6/11 - Rev. 3: Added flange on crankshaft end of cylinder and exhaust plenum.

- 5/10/11 - Rev. 4: Improved bump valve added, cylinder liner is now thick.

- 5/11/11 - Rev. 5: Added mount brackets, pillow block, extended piston stem.

- 5/25/11 - Rev. 6: Widened cylinder flanges, dropped water vent, added sensor vent, cylinder liner to scale.

- 7/20/11 - Rev. 7: Merged valve cover and mounting bracket. Added oiler.

1. Steam Fires

2. Steam Expands

3. Steam Vents

Description

This is a single-action uniflow steam engine that uses a bump valve to admit steam and an exhaust vent to emit cooled steam.

Design Features:

- Simple design with a mix of fabricated and off-the-shelf parts.

- Modular and stackable - cylinders can be ganged together to increase power.

- Easy assembly - minimal welding

- Repairable - comes apart for cleaning, maintenance, and repair.

- Easy fabrication - lathing, milling, cutting, and drilling.

- Self-lubricating - oil sprays.

- Crank shaft can be configured for multiple cylinders.

Sub-assembly Designs:

- Steam Engine Design/Bump Valve

- Steam Engine Design/Cylinder

- Steam Engine Design/Crank Shaft

- Steam Engine Design/Piston

- Steam Engine Design/Lubrication

- Steam Engine Design/Exhaust

Alternative Designs: