Sawmill: Difference between revisions

| Line 11: | Line 11: | ||

=Sawmill Research= | =Sawmill Research= | ||

[[Sawmill Research]] | |||

=Sawmill - Design Calculations= | =Sawmill - Design Calculations= | ||

Revision as of 03:13, 4 February 2009

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

Please answer any questions on the Sawmill_Questions page if you can. Thank you!

Product Definition

Sawmill Design Rationale

Sawmill Research

Sawmill - Design Calculations

Available Power

- Review of LifeTrac hydraulic power calculations - LifeTrac#Calculations - shows that we have total 29 gpm available at 3300 PSI, or a lower flow at 3600 PSI.

- Hydraulic power is defined as Flow x Pressure. The hydraulic power supplied by a pump: P in [bar] and Q in [lit/min] => (P x Q) / 600 [kW]. Ex. Pump delivers 180 [lit/min] and the P equals 250 [bar] => Pump power output = (180 x 250) / 600 = 75 [kW]. 75000W / 745.7 = 100.58hp

- LifeTrac has 91 l/min available from the auxiliary hydraulics, and 228 bar - 91x228/600/.746 = about 46 hp.

- 24 gallons/minute = 91 liters/minute (of 29 gpm total LifeTrac power, 5 is diverted into tractor steering)

- 1 bar = 14.5 psi, 3300 PSI = 228 Bar

- LifeTrac has 91 l/min available from the auxiliary hydraulics, and 228 bar - 91x228/600/.746 = about 46 hp.

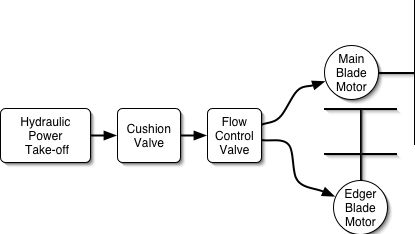

Power Distribution Between 2 Sets of Blades

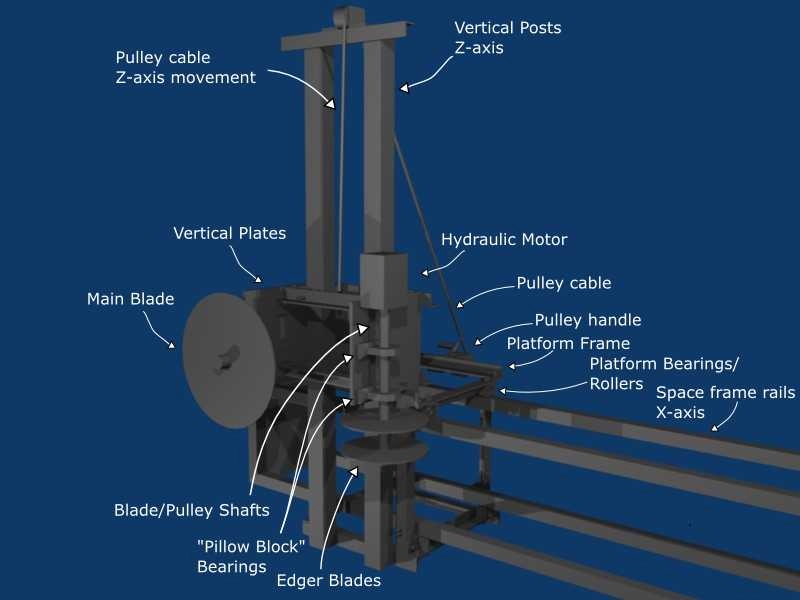

The sawmill has 2 sets of blades: the main blade and the edger blades - see 3d picture - #3D_CAD_-_Using_Blender. Hydraulic power must be distributed to both sets. One motor powers the 2 edger blades, and another motor powers the main blade. Power - or hydraulic fluid flow - must be distributed to both sets of motors to accommodate various cutting scenarios:

- Assume that main blade is 20 inches in diameter, and edger blades are 10"

- Square lumber profiles, such as 2x2s and 4x4s (size in inches)

- Rectangular lumber profiles - such as 2x4s, 4x8s, up to 1x9s

- The case where square profiles are cut requires one cut by the main blade, and equivalent cuts by the edger blades. Since there are 2 edger blades, this requires the condition where the edger blades require twice as much power as the main blade. The power distribution strategy and motor sizing should allow for this. Power ratio of main (Pm) to edger (Pe) blades: Pm/Pe = 1/2

- In the extreme opposite case, such as when cutting 1x10, the power ratio is Pm/Pe = 5

- The middle case exists for 2x4s, 4x8x - where Pm/Pe = 1

Hydraulics Design for 2 Sets of Blades

The point is that flow control must exist where the amount of power that goes to each blade can be varied. Power is controlled by fluid flow rate - or a flow control valve in practice:

Would this valve from Surpluscenter [1] do?:

Hydraulic Motors

Edger Blades - 10"

Main Blade - 20"

Sawmill Design developments

See Sawmill Design Developments

Sawmill - Current Work

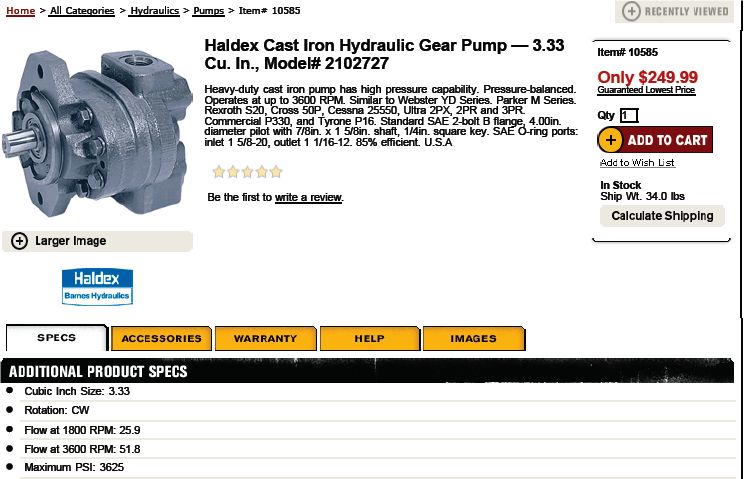

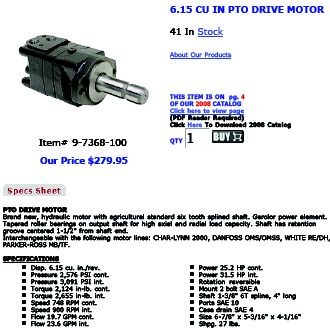

We have a hydraulically-driven PTO motor as a start. It will be powered by LifeTrac. LifeTrac has this pump from Northerntool - [2]:

All hoses are already available - it is part of our flexible open source tractor infrastructure. Here are the motor specifications, from Surpluscenter.com:

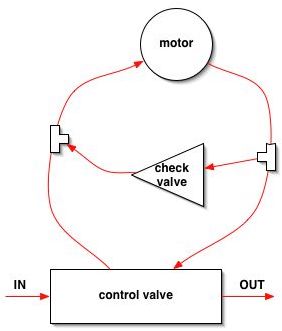

Here is the hookup diagram:

Note: Since we have 3600 PSI available, we can run 2 of these motors in series to match available power more closely.

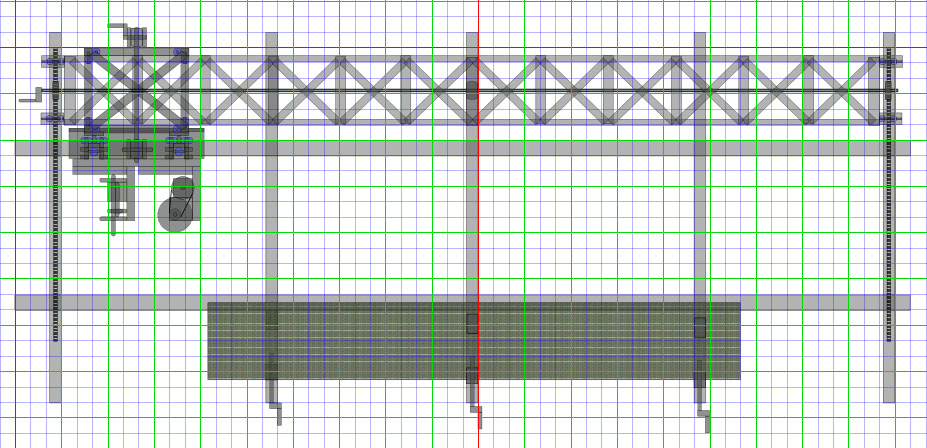

A very preliminary prototype drawing, top view:

3D CAD - Using Blender

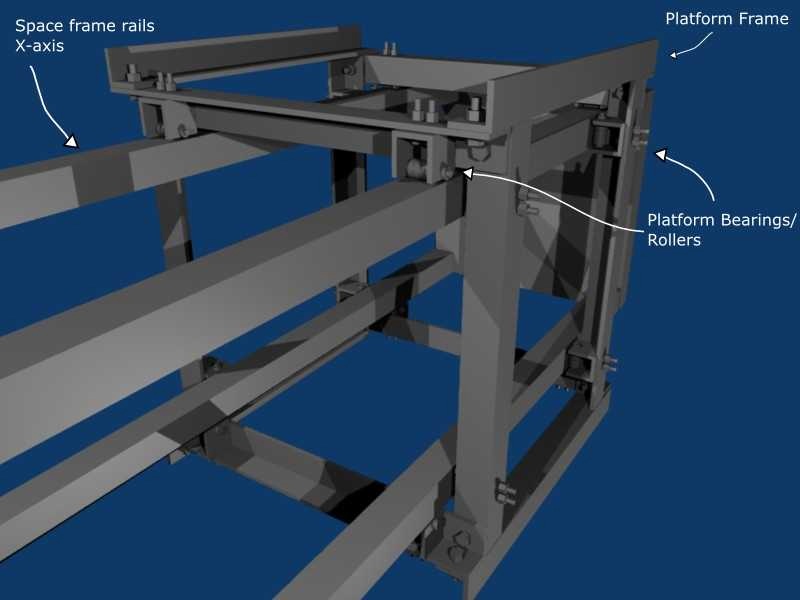

Preliminary 3d pictures of the sawmill:

Sawmill Deployment

Implementation

Design

- With design rationale, put it up for review on Red Pages

- Finish design in 3d, go through cutting process

- Get feedback on design, post on sawmilling forums

- Iterate design and feedback until design is finalised

- Make bill of materials for final design

Test Construction

- Build space frame and platform frame as a first test, to test x axis motion

- Test x axis motion

Construction

- Purchase one blade, 30", 2 blades, 12"

- Build cutting head - gear up the blade

- Install all safety devices before operating

- Test sawmill operation without blades attached

Bill of Materials

Development Work Template

- Sawmill - Product Definition

- Sawmill - Design Evolution

- Sawmill - Technical Design

- Sawmill - Deployment and Results

- Sawmill - Documentation and Education

- Sawmill - Resource Development

- Sawmill - Identifying Stakeholders

- Sawmill - Grantwriting

- Sawmill - Collaborative Stakeholder Funding

- Sawmill - Tool and Material Donations

- Sawmill - Charitable Contributions