CEB Press/Manufacturing Instructions/Soil loading drawer: Difference between revisions

Jump to navigation

Jump to search

Hint: It might help to use angle iron tacked to your table and the sides, so it insures they are vertically square. This also makes it a bit easier to align everything else.

Hint: It might help to use angle iron tacked to your table and the sides, so it insures they are vertically square. This also makes it a bit easier to align everything else.

| Line 96: | Line 96: | ||

===Step 7: Grind the entire drawer flush=== | ===Step 7: Grind the entire drawer flush=== | ||

{{Warning|There cannot be any outstanding bumps or welds anywhere; the drawer will be sliding in and out of a tight spot and bumps will catch on the frame crossmembers.}} | {{Warning|There cannot be any outstanding bumps or welds anywhere; the drawer will be sliding in and out of a tight spot and bumps will catch on the frame crossmembers.}} | ||

*Make sure there's no welding spatter where the rollers will be rolling. Grind any off with a small grinder. | |||

===Step 8: Check the Rails=== | ===Step 8: Check the Rails=== | ||

Revision as of 21:26, 23 August 2011

| |||||||||||||||||||||||||

Tools Required

Materials Required

| ID | Quant | Type | Length | Total | Name | Detail |

Diagrams

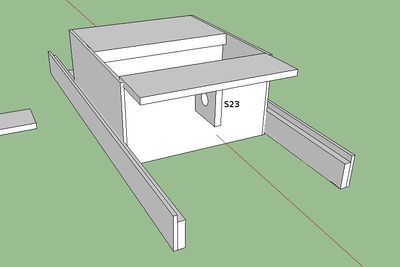

Drawer Parts

Drawer Assembly Step 1

Drawer Assembly Steps 2-3

Drawer Assembly Steps 4-5

Drawer Assembly Step 9

Fabrication Steps

(note: part numbers refer to the recently-published parts list on the Bill of Materials page)

Step 1: Weld Press Plate and Spacer Assembly:

- a) Lay the spacer tube(S24) on top of the press plate(S26), align the sides and make the back edge flush.

![]() Warning: Ensure all edges are tight and squared; this piece is critical, it must be a uniform height throughout the entire item. Grind off any imperfections.

Warning: Ensure all edges are tight and squared; this piece is critical, it must be a uniform height throughout the entire item. Grind off any imperfections.

- b) Tack weld the two together in many places (at least 3 on each side) to ensure nothing will warp.

- Double check everything for squareness!!

- c) Weld the two together on all edges where they touch.

![]() Hint: It is a good idea to weld in 1” or 2” increments, skipping around to different places to prevent warpage.

Hint: It is a good idea to weld in 1” or 2” increments, skipping around to different places to prevent warpage.

- You will need to weld multiple layers where the tubing is rounded.

- d) Grind off any weld which prevents the vertical support (S31) from being square and flush with both the spacer tube and the press plate.

- e) Weld the vertical support to the press plate and spacer tube assembly.

- f) Grind down the welds on the open end of the tube so they are flush with the rest of the tube.

Step 2: Tack Sides

- a) Lay the spacer/press plate assembly down so the press plate is touching the table.

- b) Align side pieces(S29) with spacer and press plate assembly. Insure the two are square vertically and horizontally with the spacer, and that everything is touching the table.

- Also, it may help to use paper shims between the sides and the tube to properly space them.

- c) Tack the sides to the tube on all sides in multiple places except where it is touching the table. Add a few 1" seams to prohibit them from moving.

Step 3: Tack back

- a) Place the back piece (S22).

- b) Tack the back piece in a few spots, with a 1" seam on each side.

Step 4: Tack Roof, Inner Rails

- a)Grind off the welds for the back and side pieces so that the entire drawer is flush.

- b)Flip the drawer over and tack the sides from the top.

- c) Place the roof(S25) and inner rails(S27) in their respective places. Ensure inner rails are perfectly parallel (varying no more than a 16th of an inch) and square throughout the entire length.

- d) Tack them in multiple places except where they are touching the table.

Step 5: Tack outer rails (S28)

![]() Warning: Ensure they are perfectly parallel; otherwise they will leave the roller guides. Insure it varies no more than 1/16" over the entire length.

Warning: Ensure they are perfectly parallel; otherwise they will leave the roller guides. Insure it varies no more than 1/16" over the entire length.

- Tack them in multiple places except where they are touching the table.

Step 6: Weld entire drawer

- All the seams should be completely welded except the difficult to reach places between the inner and outer rails, those can be welded about 50%.

- You may want to grind off the welds in between passes around the drawer to allow it to cool.

Step 7: Grind the entire drawer flush

![]() Warning: There cannot be any outstanding bumps or welds anywhere; the drawer will be sliding in and out of a tight spot and bumps will catch on the frame crossmembers.

Warning: There cannot be any outstanding bumps or welds anywhere; the drawer will be sliding in and out of a tight spot and bumps will catch on the frame crossmembers.

- Make sure there's no welding spatter where the rollers will be rolling. Grind any off with a small grinder.

Step 8: Check the Rails

- The rails likely got warped outwards on the side with the back while you were welding.

- If they are not still paralell, you will need to pinch them inwards so that they are. You can do so using two C-Clamps.