CEB Press/Manufacturing Instructions/Hopper sheet metal

Jump to navigation

Jump to search

| |||||||||||||||||||||||||

Tools Required

- Torch

- Welder

- Hole punch with 3/4" dies

Materials Required

- Door Hinges (12)

- 1/2" x 1 1/2" bolts (12)

- 1/2" washers (12)

- 1/2" lockwashers (12)

- 1/2" nuts (12)

- one 5X10 or two 4X8 sheets of 1/8" steel

- 24' of 1/8" thick x 3" or 4" flatbar: Cut into 3' (8 total) pieces.

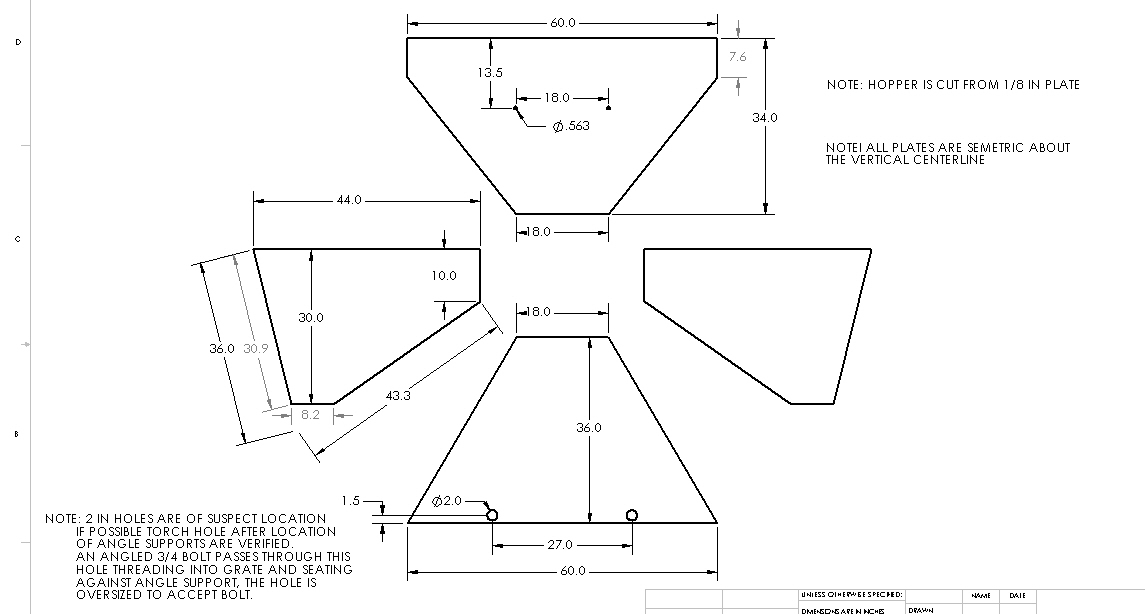

Diagrams

old design DXF File

Fabrication Steps

Note: there are holes in the above diagrams which won't be torched until the hopper installation.

Prepare the hinge plates

- Punch 3/4" holes in 4 of the hinge plates as shown. The hole locations are not critical.

- Place three hinges between one of the holey plates, and one without holes to weld.

- Make sure the plates are a 1/2" apart or more, otherwise the metal won't hinge enough to attach to the hopper.

- The pins inside the hinge should all be facing the same direction; these will need to be facing down when the hopper is erected so that the pins won't jiggle out over time.

- On two of the hinge plates, the pins should face right, and the other two, they should face left, for the reasons stated above.

- Make sure the side of the hinge that sticks out most is on the top; this way it won't interfere with the hopper metal below when installing the hopper.

- Plug weld thru the holes in the hinges to the plates below, joining all 3 hinges to each plate.

Mounting the hinge plates to the hopper metal

- Torch the hopper shapes. (See diagrams above)

- Get one of the side pieces and clamp the holey side of the hinge plate to one side of it.

- Make sure that when the side piece is in place and vertical, the hinge pins will be facing down (otherwise they could vibrate out).

- Clamp it so that it has just enough clearance for the other hopper metal, so there will be as small of a gap as possible once the hopper is assembled.

- Transfer punch thru the holes using a 1/2" transfer. Put the transfer in the bottom of the hole, near the edge of the hopper metal.

- Mark both pieces to ensure this exact plate goes back to this side.

- Repeat the above steps for the opposite side of the side piece, with a different hinge plate, Still insuring the pins will be facing down.

- Repeat steps 2-4 the same for the other side piece. Make sure that it will be a mirror image of this one, not oriented the same. In other words, prep the hinge plates on the opposite side as before.

- Punch all of the 1/2" holes where you center marked.

- Take one of the punched side pieces, and flip it over, so that the side with all the marks is touching the table.

- Place 1/2" bolts thru the holes and weld them.

- Do the same for the other side piece.

- Flip the side pieces over and match the put the corresponding hinge plates onto each set of bolts.

- Bolt them down tightly using a washer, lock washer, and nut on each bolt.

See Hopper Installation for how to mount it to the machine.