Sawmill/Development

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

Please answer any questions on the Sawmill_Questions page if you can. Thank you!

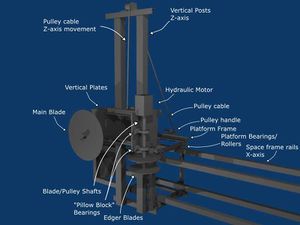

A sawmill enables custom lumber production on site using locally available timber. We are particularly interested in a dimensional sawmill. A dimensional sawmill is a circular blade sawmill for producing dimensional lumber. It consists of two blades attached at a right angle to one another, allowing the production of a dimensional member in one pass of the mill. Distributed sawmilling has the potential for distributing the production of dimensional lumber, thus creating less dependence on clear-cutting of lumber plantations. Wood construction is one of the earliest methods of building shelter. Current lumber production is highly concentrated industry save the specialty wood shops producing for novelty wood workers. Unsound harvesting practices and high transportation costs make commercial lumber environmentally costly. Timber can be locally harvested. With a simply designed, low cost sawmill we can produce fine quality lumber sustainably and economicaly.

Product Definition

Sawmill Design Rationale

Sawmill Research

Sawmill Development Plan

Overview

Design

Current phases in bold. Next phase in italic.

- With design rationale, put it up for review on Red Pages

* Design in 3d, go through cutting workflow, split up design into pieces and finish them one at a time

* Get feedback on sub-piece design, post on sawmilling forums

- Iterate design and feedback until design is finalised

- Make bill of materials for final design

Test Construction

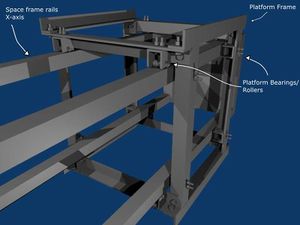

- Build space frame and platform frame as a first test, to test x axis motion

- Test x axis motion

Construction

- Purchase one blade, 30", 2 blades, 12"

- Build cutting head - gear up the blade

- Install all safety devices before operating

- Test sawmill operation without blades attached

Sawmill Design Log

See Sawmill Design Developments

Sawmill Design 1

Sawmill Design 2

Sawmill - Design Calculations

Sawmill - Current Work

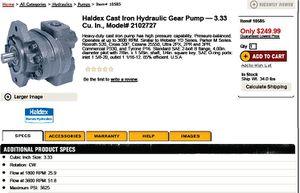

We have a hydraulically-driven PTO motor as a start. It will be powered by LifeTrac. LifeTrac has this pump from Northerntool - [1]:

All hoses are already available - it is part of our flexible open source tractor infrastructure. Here are the motor specifications, from Surpluscenter.com:

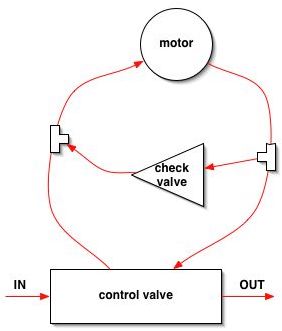

Here is the hookup diagram:

Note: Since we have 3600 PSI available, we can run 2 of these motors in series to match available power more closely.

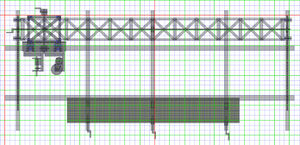

A very preliminary prototype drawing, top view:

3D CAD - Using Blender

Preliminary 3d pictures of the sawmill:

Bill of Materials

Collaboration

Current Steps

See Sawmill_Project_Status for detailed current status and past history actions.

Current Stage:

Developments Needed

Collaborators Sign-Up List

If you'd like to collaborate on this project please email the Project Lead listed below with the following

Subject: Name, email, and Skype are preferable.

Listed below are the collaborators on this project

- Temporary Project Lead - {Need Name of Lead} project lead's email dot com, phone xxx.

List of Prototyping Collaborators with Access to Fabrication Capacity

Resource Development

See Sawmill - Resource Development.

Documentation and Education

section unfinished (this section is dedicated to preparing and disseminating results, in the form of publications and technical reports.)