CEB Press/Manufacturing Instructions/Hopper supports: Difference between revisions

Jump to navigation

Jump to search

| Line 22: | Line 22: | ||

[[Image:cutaway.jpg|thumb|The cutaway at the top of the hopper supports.]] | [[Image:cutaway.jpg|thumb|The cutaway at the top of the hopper supports.]] | ||

[[Image:supportbolts.jpg|thumb|200px|The shaker in place, ready to weld.]] | [[Image:supportbolts.jpg|thumb|200px|The shaker in place, ready to weld.]] | ||

#Torch the necessary areas on the supports. | #Torch the necessary areas on the supports (see diagram). | ||

#*The holes for the hopper mounting need to be 30" away from the bottom side. Mark 30" on the opposite tubing walls and torch 1/2" holes. Insure a 1/2" bolt goes all the way thru. | #*The holes for the hopper mounting need to be 30" away from the bottom side. Mark 30" on the opposite tubing walls and torch 1/2" holes. Insure a 1/2" bolt goes all the way thru. | ||

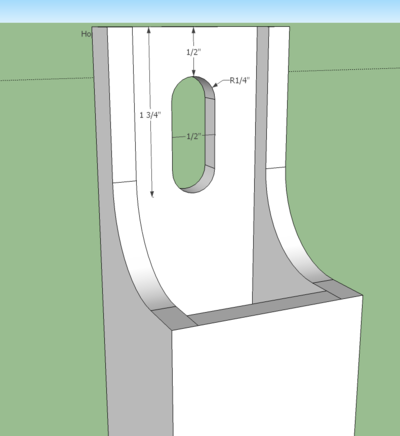

#*The hole for the grate mount needs only be on one side, make it a slot, about 1 1/4" long, 1/2" wide. Torch away the opposite wall to make it easier to access the bolt. See diagram. | #*The hole for the grate mount needs only be on one side, make it a slot, about 1 1/4" long, 1/2" wide. Torch away the opposite wall to make it easier to access the bolt. See diagram. | ||

| Line 29: | Line 29: | ||

#Tighten 3/4" bolts with nuts to the [[CEB Press/Manufacturing Instructions/Soil Shaker|Soil Shaker]] so the bolt head is where the hammer will be. | #Tighten 3/4" bolts with nuts to the [[CEB Press/Manufacturing Instructions/Soil Shaker|Soil Shaker]] so the bolt head is where the hammer will be. | ||

#Prop this up on the leg, so the shaker mount is high enough above the 30" hole that a washer and bolt can be there, and both bolts are touching the support. | #Prop this up on the leg, so the shaker mount is high enough above the 30" hole that a washer and bolt can be there, and both bolts are touching the support. | ||

#Mark which side of the shaker you welded the bolts for. | |||

#Tack the bolts in place, remove the nuts and dismount the shaker. | #Tack the bolts in place, remove the nuts and dismount the shaker. | ||

#Protect the threads, and finish welding to the support. | #Protect the threads, and finish welding to the support. | ||

#*You are only doing this on one of the supports, the other side, you will do in place, so the spacing is correct. | #*You are only doing this on one of the supports, the other side, you will do in place, so the spacing is correct. | ||

Revision as of 03:15, 24 October 2011

| |||||||||||||||||||||||||

![]() Warning: The documentation for the CEB Press is undergoing a thorough overhaul. CAD models and written directions are presently obsolete. For more information, see Talk:CEB_Press#Documentation_overhaul_in_progress. When the models, specifications and text on this article have been thoroughly reviewed, updated when necessary, and confirmed as whole and accurate, this warning may be removed.

Warning: The documentation for the CEB Press is undergoing a thorough overhaul. CAD models and written directions are presently obsolete. For more information, see Talk:CEB_Press#Documentation_overhaul_in_progress. When the models, specifications and text on this article have been thoroughly reviewed, updated when necessary, and confirmed as whole and accurate, this warning may be removed.

The hopper supports attach to the hopper, and attaches to the main frame via leg holders. They also hold the Soil Shaker

Tools Required

- Torch

- Welder

Materials Required

- 2 pieces 48" long - 1/4”x2”x2” tubing

- Soil Shaker (this should be dis-assembled, although you can do it assembled, its just heavier and more difficult to manouver.)

- 3/4"x1 1/2" bolts (4)

Diagrams

Wanted: fix this to show cut away at top, and bolt locations.

Fabrication Steps

- Torch the necessary areas on the supports (see diagram).

- The holes for the hopper mounting need to be 30" away from the bottom side. Mark 30" on the opposite tubing walls and torch 1/2" holes. Insure a 1/2" bolt goes all the way thru.

- The hole for the grate mount needs only be on one side, make it a slot, about 1 1/4" long, 1/2" wide. Torch away the opposite wall to make it easier to access the bolt. See diagram.

- Grind away any slag.

- Lay one support on the table, with the grate mount hole touching the table.

- Tighten 3/4" bolts with nuts to the Soil Shaker so the bolt head is where the hammer will be.

- Prop this up on the leg, so the shaker mount is high enough above the 30" hole that a washer and bolt can be there, and both bolts are touching the support.

- Mark which side of the shaker you welded the bolts for.

- Tack the bolts in place, remove the nuts and dismount the shaker.

- Protect the threads, and finish welding to the support.

- You are only doing this on one of the supports, the other side, you will do in place, so the spacing is correct.