Steam Engine Intro: Difference between revisions

(→Design) |

|||

| Line 118: | Line 118: | ||

*Marcin says: I looked at this in detail 2 years ago, and purchased plans. When I asked for references of people who built this engine, the inventor did not provide me with any. I became suspicious about the effectiveness of the engine. Since then, I've heard reports from several sources that longevity and performance are questionable. In summary, if this worked as stated, we would see a large number of implementations on the internet. Since these are not to be seen, it does not appear to be a promising design. | *Marcin says: I looked at this in detail 2 years ago, and purchased plans. When I asked for references of people who built this engine, the inventor did not provide me with any. I became suspicious about the effectiveness of the engine. Since then, I've heard reports from several sources that longevity and performance are questionable. In summary, if this worked as stated, we would see a large number of implementations on the internet. Since these are not to be seen, it does not appear to be a promising design. | ||

= Product Ecology = | = Product Ecology = | ||

| Line 129: | Line 130: | ||

* Steam Powered Cars and Trucks | * Steam Powered Cars and Trucks | ||

* Solar Concentrator, [[Solar Fire]] | * Solar Concentrator, [[Solar Fire]] | ||

= Specifications = | = Specifications = | ||

Revision as of 02:46, 30 May 2011

Main > Energy > Steam Engine

| Steam Engine | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Description

We are proposing an open-source steam engine project, to deliver a highly-efficient modern steam engine with the following features:

- Scalable power from 5 to 100 horsepower

- Modular design for easy building, maintenance, and repair

- Simple uniflow design - steam flows in a single direction from input valves to exhaust port(s)

- Modular crankshaft design to allow additional units to be added

Project goals include:

- Minimize expensive off-the-shelf components

- Minimize fabrication costs

- Easy to assemble and disassemble

- Easy to troubleshoot and repair

Steam power is not taught in general. For mastering this topic, we need a Steam Power Reading List.

I have some of this material from Tom Kimmel, of Kimmel Steam Power

Mike Brown offers a reading list here

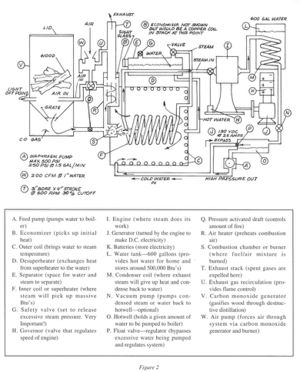

Description of this system by author and excellent background info on home power steam [1]

Apparently Skip Goebel thinks similar to me about electronically controlled steam engines taken from [2]

Additional Information

- Category: Steam Engine

- Blog post and interview with Harry Schoell

- Related Forum - discussion forum.

- Steam Engine/Correspondence - reviews, messages, letters,etc.

- Steam Engine/Terminology - terms, jargon, abbreviations, etc.

- Steam Engine/Index - steam engine pages organized by topic.

Project Team

OSE:

- Marcin Jakubowski, Visionary

- Mark Norton, Project Manager

- Andrew Buck, Simulations, CAD

Design Reviewers:

- Tom Kimmel, SACA

- Ken Helmick, SACA

- Harry Schoell, Cyclone Tech. ??

Design Rationale

Although it is a matter of some debate, there are many who feel that our global civilization has past the (so called) point of peak oil. | Peak oil refers to the point in time when easy sources of petroleum have been exhausted. Past that point, demand continues to rise (largely pegged to global population growth) but production rolls off. If we accept that we have past the point of peak oil, then how will we maintain civilization's need for energy? While part of the answer lies in reducing consumption, a bigger part lies in alternative sources of energy. The Open Source Ecology project is exploring a number of alternative energy sources, the Open Source Steam engine is the focus of this OSE project.

Steam engines have a number of benefits over other kinds of motive power:

- Relatively uncomplicated, few moving parts (compared to other engines)

- Driven by steam, produce in a variety of ways (boiler, solar concentrator, etc.)

- Can be made modular: steam source, controller, cylinder, crankshaft

- Scalable power: connect more steam engine units onto a common crankshaft

- Easy to build: most parts can be fabricated from stock materials

Additional reasons to design and build an open source steam engine include:

- Relevant as an appropriate technology choice in both poor and rich countries, when coupled to flash steam generators

- Basis for another kind of Power Cube

- May be coupled directly to linear hydraulic pump (feasibility study required)

Design

Overall design of the Open Source Steam Engine breaks down like this:

- Existing and Historic Designs

- OSE Engine Designs

- Steam Engine Design/2009 - an older design attempt

- Steam Engine Design - current design description

- Steam Engine Design/Solenoid - a future design

- Steam Engine Design/Valves - notes on different kinds of valves

- Steam Generator Designs

Summary of Proposed Design

The current OSE Modern Steam Engine is based on design developed for the White Cliffs solar power station in NSW, Australia (see Steam Engine Design/White Cliffs). While the White Cliffs engine used a converted diesel engine, the essential concept is the same: a uniflow steam engine using a bump valve control mechanism. Our engine is greatly simplified from the White Cliffs design. Initially, it will be a single cylinder (scalable by adding more to a common crankshaft) driven by steam from a boiler or solar concentrator (such as Solar Fire). Two bump valves are activated by valve pins mounted on the face of the piston head. Just before top dead center of the cycle, the bump the steam valves open, letting new steam into the cylinder. A flywheel carries the piston past top dead center and at the cut-off point, the steam valves close. Expanding pressure causes the piston to move down the cylinder until it nears bottom dead center, at which point the piston uncovers four exhaust vents allows steam (any any condensed water) to escape the engine. An exhaust plenum is provided to capture spent steam so that it might be used for other purposes (like heating).

Typical Engines

Typical steam engine cylinders are made from cast iron. (What is the best metal to use for a steam engine?) Given that water is the working fluid, lubrication is required in the cylinder. (Is there any way to prevent corrosion otherwise?)

- Cylinder - cylinder is made from cast iron.

- To cast this cylinder from scrap iron, use a (how many?) pound melt, and use a simple melting furnace such as (here?)

The simplest way to cast a cylinder

Azuredu 03:43, 27 February 2009 (PST) Suggestion. To start with, why not try to adapt a recovered moto engine.

skaar: try iron gas pipe?

jerryshaw: it may not be fully feasible yet, or maybe it already is, but high temperature plastics may actually be usable. Temperature and pressure is well below an internal combustion engine, and there are no plastic IC engines but we already have plastic intake manifolds right next to very hot components, say 400 degrees in the intake of some supercharged engines. If plastic works it would make for very inexpensive steam engines, as well as fairly light weight ones, making it easy to motorize things everywhere. They could be cheaply manufactured from a cooperative owned plant, or perhaps the plastic formulations could be tweaked over time to even eventually use bioplastic and be printed in your own RepRap machine! http://reprap.org/bin/view/Main/RepRap But until then don't entirely rule out plastic. It should at least work with basic steam, maybe not superheated steam. I have even heard of wood(!) being used to make a working steam engine (though I think it used iron piston rings, the piston and cylender and head were wood) although I wouldn't expect life to be terribly long.

- I think an aluminum/silicon alloy would be worth considering. It does not shrink much as it solidifies, and can be cast at a reasonable temperature, using plaster molds (lost wax or, when scaled up, a re-usable polyurethane master). It's also fairly strong, reasonably corrosion-resistant, can be used to make heat exchangers, and is widely available as scrap, e.g. aluminum engine blocks are made from a suitable alloy. David Gingery wrote some books that might be helpful.

Green Steam Engine

An alternative engine design that may be worthy of further evaluation can be found [3] here. It looks as though o-rings are used in place of traditional tight tolerance cast iron cylinder boring. Presumably this method is only good for low pressure and temperature steam. The linkage and valve system is highly innovated and would require no precision machining.

- Discussion of the Green steam engine:http://www.alternative-energy-news.info/green-steam-energy/ It does indeed seem that the o-ring method of sealing is incapable of handling high steam temps and pressures and the design is therefore inherently inefficient.

- Marcin says: I looked at this in detail 2 years ago, and purchased plans. When I asked for references of people who built this engine, the inventor did not provide me with any. I became suspicious about the effectiveness of the engine. Since then, I've heard reports from several sources that longevity and performance are questionable. In summary, if this worked as stated, we would see a large number of implementations on the internet. Since these are not to be seen, it does not appear to be a promising design.

Product Ecology

Describe relationship to:

- Steam Generator

- Solar Turbine - by concentrating sunlight onto a narrow pipe, we can boil water to drive a steam engine. Using a steam engine to make electricity from sunlight yields much more energy than using photovoltaic cells.

- Electric Generator

- Power Cube

- Steam Powered Cars and Trucks

- Solar Concentrator, Solar Fire

Specifications

Inch to millimeter conversion chart [4].

Specifications including dimensions are provided in Steam Engine Specifications and complete building instructions are given in Steam Engine Build Instructions. Sourcing of parts is specified in Steam Engine Bill of Materials.

Costs

(Cost estimates go here)

Additional Links

- Biomass CHP with steam engine - [5]

- 60% vapor cycle efficiency in steam engine power plant? - [[6]]

- $300/hp steam engines in production, Peru - [7]

Steam Engine History

- Brief History of the Steam Engine

- The Steam Engine

- A History of the Growth of the Steam Engine: [8]

- A Catechism of the Steam Engine:[9]

Steam Engine Primers/Groups

Primers

- http://www.pioneer.net/~carlich/RSE/RSEprimer.html

- http://www.the-nerds.org/Steam-101.html

- Promising forum with large library of working steam engine plans: http://www.paddleducks.co.uk/

Groups

Engine Plans/Products

- http://www.pioneer.net/~carlich/RSE/RSEengines.html

- http://www.nearfutures.com/products.htm

- http://www.greensteamengine.com/products.htm

- Triple Expansion Steam Engine Prints: http://www.carferries.com/triple/

- Lindsey Publications:http://www.lindsaybks.com/prod/sub/engines.html

- http://www.grahamind.com/

- http://quasiturbine.promci.qc.ca/Presse/SteamMuller050721.pdf

- These guys claim 30% efficiency on their non compunding multi cylinder steam engine http://www.energiprojekt.com/?product

- 3kW steam engine for $1375: http://www.thesustainablevillage.com/servlet/display/products/byCat/71/441/2557/

- Lots of Plans: http://www.john-tom.com/html/SteamPlans.html

- A nice simple double engine plan: http://openfarmtech.org/images/e/e0/MichelNiggelTwin.pdf

Misc

- Green wood chip burner: [10]

- Steam engine from scrap - http://www.btinternet.com/~jhpart/steam2.htm

- Vegetable Oil Based Lubricant:http://www.steamenginelube.com/chelesic.htm

- Homebrew Steam Engine Generator:http://www.otherpower.com/steamengine.shtml

- Steam Engine Manuf. Links: http://cedesign.net/steam/steam-links1.htm

- Harry Schoell's Cyclone Power http://www.popsci.com/scitech/article/2008-05/steam-under-hood http://www.cyclonepower.com/

- Oil Free Steam Engine Design for Vehicles: http://six6.region-stuttgart.de/sixcms/media.php/773/23_Platell_P.pdf

- Flash Steam Engine, Could this be advantageous http://www.huzar-power.com/steam_engines/revival/flash_steam.htm

Nick R. says, what are the limits to lathe boring diameters in cast iron? This [11] method of construction looks simple and attractive if it could be scaled up enough?