CEB Press/Manufacturing Instructions/Soil Shaker motor unit: Difference between revisions

Jump to navigation

Jump to search

| Line 25: | Line 25: | ||

== Fabrication Steps == | == Fabrication Steps == | ||

[[Image:shakerhydvise.jpg|thumb| | [[Image:shakerhydvise.jpg|thumb|400px|How to clamp the motor and where to put needle valve assembly. Note:the needle valve should be attatched to the tee in this photo.]] | ||

[[Image:shakerdone.jpg|thumb|400px|The finished shaker Note:the needle valve should be attatched to the tee in this photo.]] | |||

*Thread tape is necessary between each connection unless otherwise stated. | *Thread tape is necessary between each connection unless otherwise stated. | ||

*Always wrap thread tape clockwise when facing the threaded portion. | *Always wrap thread tape clockwise when facing the threaded portion. | ||

Revision as of 00:41, 9 October 2011

| |||||||||||||||||||||||||

![]() Warning: The documentation for the CEB Press is undergoing a thorough overhaul. CAD models and written directions are presently obsolete. For more information, see Talk:CEB_Press#Documentation_overhaul_in_progress. When the models, specifications and text on this article have been thoroughly reviewed, updated when necessary, and confirmed as whole and accurate, this warning may be removed.

Warning: The documentation for the CEB Press is undergoing a thorough overhaul. CAD models and written directions are presently obsolete. For more information, see Talk:CEB_Press#Documentation_overhaul_in_progress. When the models, specifications and text on this article have been thoroughly reviewed, updated when necessary, and confirmed as whole and accurate, this warning may be removed.

Tools Required

- Various Wrenches

- Crescent Wrench

Materials Required

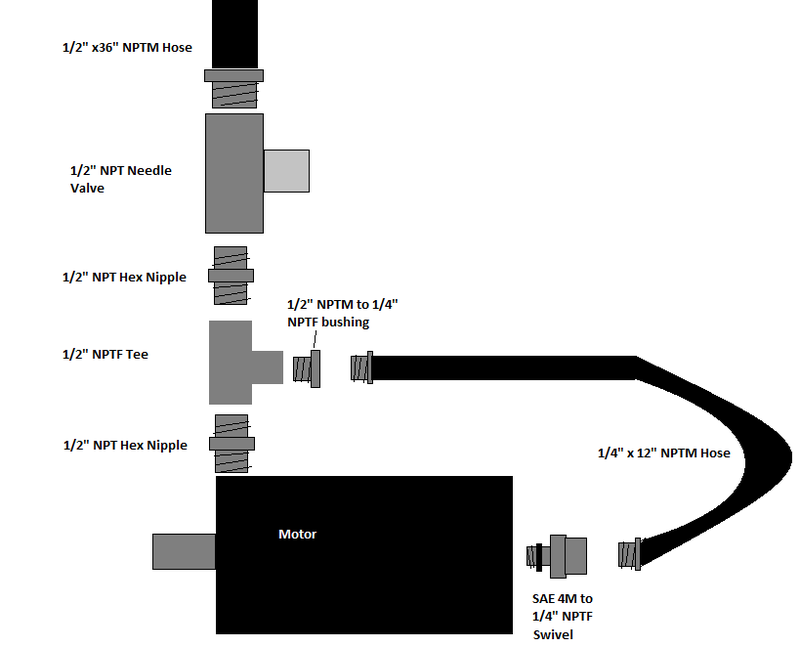

Note: NPT means national pipe thread, and refers to the interior diameter of the hoses. NPTM means a male end, and NPTF means a female end.

- Thread tape

- Shaker motor Buy

- 1/2" NPT Needle Valve (1)Buy

- 1/4"x12" NPTM Hydraulic hose (1)Buy

- 1/2"x36" NPTM Hydraulic hoses (2)

- SAE 4M to 1/4" NPTF Swivel (1)Buy

- 1/2" NPT Hex Nipple (2) Buy

- 1/2" NPTF Tee (1) Buy

- 1/2" NPTM to 1/4" NPTF bushing Buy

Diagrams

Fabrication Steps

- Thread tape is necessary between each connection unless otherwise stated.

- Always wrap thread tape clockwise when facing the threaded portion.

- Always keep the end caps on hoses and fittings until you need to take them off. They need to stay protected inside.

- Clamp the motor in a vise so that the side opposite the shaft is facing up.

- Remove the plug and install the SAE 4 adapter. This connection (and any others with an o-ring in general) doesn't need thread tape. Remove from vise.

- Your motor will probably have fluid in it, so take care that the fluid doesn't leak everywhere when you remove the plug.

- Clamp the needle valve in the vise and tighten a 1/2" nipple into it. Remove from vise.

- Clamp the Tee in the vise and tighten the other 1/2" nipple on one side of it then flip it over and tighten the needle valve/nipple to it.

- Rotate the tee in the vise and tighten the bushing and then the 1/4" hose into it. Remove from vise.

- Clamp the motor in the vise as shown in the photo.

- Remove the 2 plugs for the ports.

- Install the Tee/needle valve/ hose assembly in the left port when facing the SAE fitting. See photo.

- Get it tight, but make sure the hose is facing so you can get it to the SAE adapter.

- Tighten the 1/4" hose to the SAE adapter.

- Tighten one 36" hose into the needle valve, and the other into the other port.