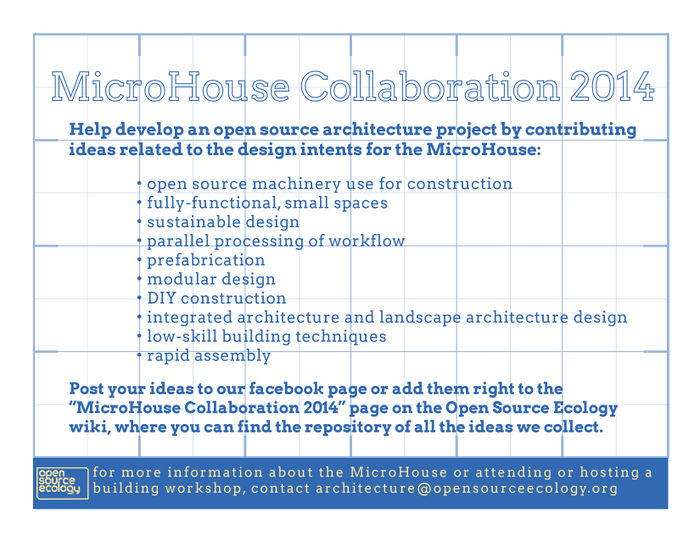

MicroHouse Collaboration 2014

Welcome to the MH Collaboration 2014

Message from Architectural Lead and Construction Manager

Thank you for visiting the repository of ideas for MicroHouse development in 2014. We are casting the net wide and gathering as many ideas as possible for the next iterations of the MicroHouse. Feel free to post items directly in the appropriate categories on this page. If one does not exist, go ahead and create it. I will manage the page to ensure consistent formatting and filing of information. Also, you can post your ideas to our facebook page if you are not comfortable editing a wiki.

Background: MicroHouse 1 Development

Overview

The MicroHouse 1 was constructed at Factor e Farm in the fall of 2013. There were several ambitious goals for the project:

- use open source equipment

- DIY construction

- fully functional space for two people with 12'x12' interior dimensions with a partial loft

- parallel process prefabrication with site-building: swarming construction

- rapid assembly - with the ultimate target of a one-day build

- sustainable design, including passive heating and cooling

- design for tolerancing - i.e. make construction methods suitable for those without experience

- modular components for easy expansion and remodeling

Links

The MicroHouse 1 Development Board: http://opensourceecology.org/wiki/Microhouse_1_Development_Board

Architectural Lead and Construction Manager Personal Work Log: http://opensourceecology.org/wiki/Chris_Reinhart_Log

General Comments, Observations, Requests, Critiques, etc

- Spencer Christopherson says, "I would love to see an earth sheltered version of micro house."

- Rose Mills-Arabia says, "I would love to see a small fireplace built into the MicroHouse. Maybe with the top sticking out and an opening directly above where you can cook food."

Small Spaces Design Ideas

This is the category for general ideas on small houses, including those designed by collaborators or other precedents that have been collected.

Macy Miller's $11,000 House

Shared by Rob Kirk on December 19, 2013

Macy Miller is a 30-year-old architect that designed and built this beautiful small home on a trailer frame. It looks incredible!

Here's a link to an article about the project: http://homes.yahoo.com/blogs/spaces/architect-s-big-idea--tiny---11-000-house-200544175.html

Belgian Egg-House

Added by Chris on Nov 30, 2013

Catherine Austin Fitts sent me this link to an interesting egg-shaped design for a tiny home, by firm dmVA: http://www.designboom.com/architecture/dmva-blob-vb3/

Here's another link to a different article on the home: http://www.theverge.com/2013/10/6/4809670/belgian-egg-house-combines-bed-bath-and-kitchen-in-self-contained-unit

Images from the first link listed above.

Link to dmVA home page: http://www.dmva-architecten.be/v2/index.php

Nomad Micro Homes

Added by Chris on Nov 25, 2013

Rob Beddingfield posted a link to Nomad Micro Homes with this comment, "This microhouse makes there whole bathroom into a shower stall, it looks like that allows them to put a sink in there."

He was referencing this picture:

You can check out Nomad Micro Homes here: http://www.nomadmicrohomes.com/

I think this fits right in to the modular component design. We could make the whole unit and move it into place with stub-outs, utility module style. Pop on the fixtures once it's in place, unless we can effectively deal with the weight issue. What's the lifting power on the LifeTrac? We could easily calculate the weight of a given design. What I like about the idea, especially if we include the utility module as part of it, is that we have just a single component for the downstairs. Would be tough with human power, though. It took three of us to move the Utility Module around. If it was a single module, it would have to go in first and be built around. That's not necessarily a problem. Anyway, this is a very compelling suggestion. -Chris

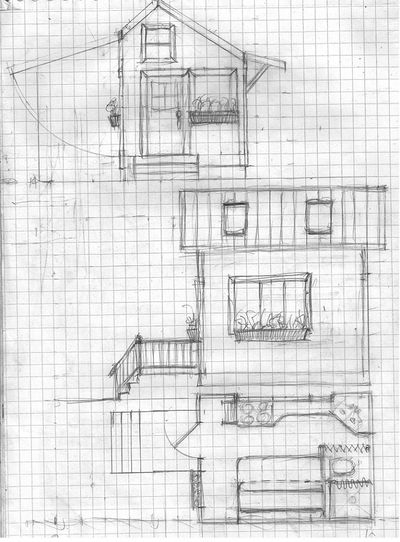

Tom Mallard's Small Home Idea

Added by Chris on Nov 25, 2013

Thanks, Tom, for posting these ideas to the OSE facebook page in response to the MicroHouse infographic. Your design is very cool!

Here's what Tom had to say about it:

"This is a 10ft x14ft tiny home with a loft that's active solar-thermal using the roof as the heat-cold source and water thermal-mass in pipes below the floor & in the high wall, toilet & gray water on separate piping and drinking water collection from rain to a cistern.

A patio roof folds down in winter on the north side, floor plan has built-ins a lot of shelving the table drop to a dbl bed, room for another in the loft that has a lot of drawer storage, ladder to it not shown."

Earth Block Construction

Auroville Earth Institute: Arches, Vaults, and Domes

This link was posted to the page by Micah Chiri, with the following comment: "I've suggested this before and will again. With this implementation, the whole MicroHouse could be constructed with earth material."

Auroville website: http://www.earth-auroville.com/compressed_stabilised_earth_block_en.php

DIY Construction

This category includes ideas of DIY processes.

Open Source Equipment

This category is for ideas about creative ways to use open source equipment in the construction process.

Parallel Processing

This category is a repository for ideas about workflows that parallel process components that later come together in assembly.

Prefabrication and Rapid Construction

Here is place for ideas and precedents on prefabricated projects and other rapidly built projects.

Jean Prouve'

Jean Prouve'. Metalworker. Self-taught architect. He made serious explorations into prefabrication that I have just become aware of. It's a great story.

Modular Library Studio by 3rd Space

Thanks, Catarina, for sharing this prefabricated project by 3rdSpace.

Image from http://design-milk.com/modular-library-studio-3rdspace/modular-library-studio-3rdspace-3a-empty/ Image from http://design-milk.com/modular-library-studio-3rdspace/modular-library-studio-3rdspace-1/

Article on the project on Design Milk: http://design-milk.com/modular-library-studio-3rdspace/

3rdSpace architects website: http://www.3rdspace.co.uk/

Sustainable Design

Ideas on sustainable design for the MicroHouse are found in this category.

Low-Skill Techniques

Ideas on how to creative an inclusive process for those that have little or no construction experience.

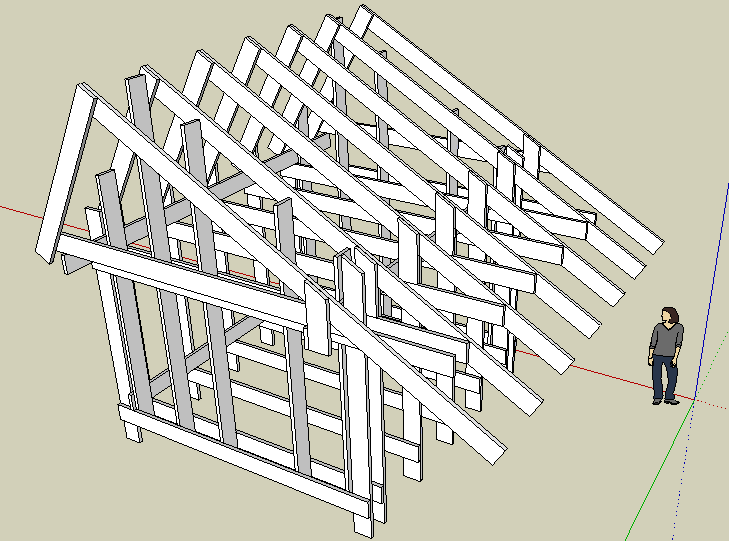

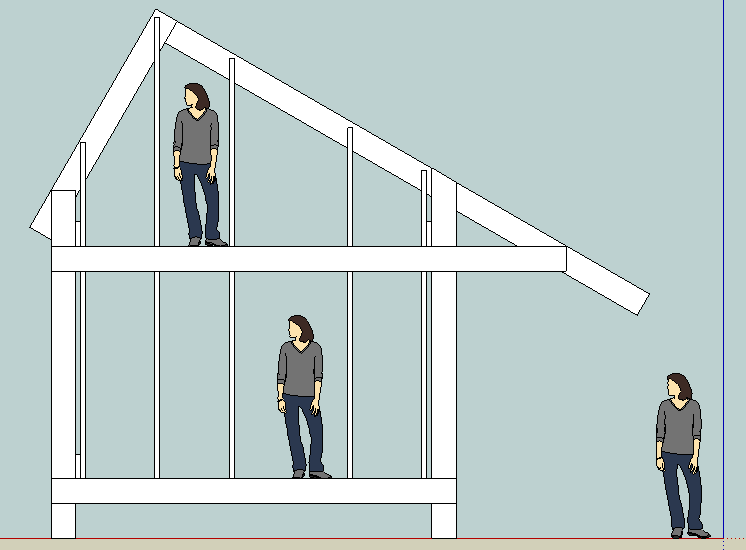

MicroHouse + WikiHouse

Marcin and I had talked about this, and Alan Hynek made the suggestion on the facebook page. What are the possibilities with a mash-up of the MH + WH?

WikiHouse webpage: http://www.wikihouse.cc/

Simpler WikiHouse - basic frame structure impression (by Alan Hynek):

- 12' x 12' interior size

- easy DIY, no CNC milling just cutting to length and angle

- Barn Rising style of constructing, but way much easier measuring and cutting (no complicated joints) and light to raise

- 2x10 timber would be strong, but also quite heavy to lift. 1x10 could possibly do quite well and one frame section would weight about 90 kg (dry pine construction wood)

- possible fastening methods: nails and hammers (cheap, fast and accessible), wood screws and impact driver (more expensive, easier, probably stronger)

- roofed area for small porch

- usable loft (bedroom)

- suitable for light roofing (boarding + shingles, corrugated steel)

- walls could be insulated between boards with different materials

- possibility of scaling by adding frames in the middle and separating rooms (making house longer)

SketchUp file - File:MH-WK-0.1beta.skp

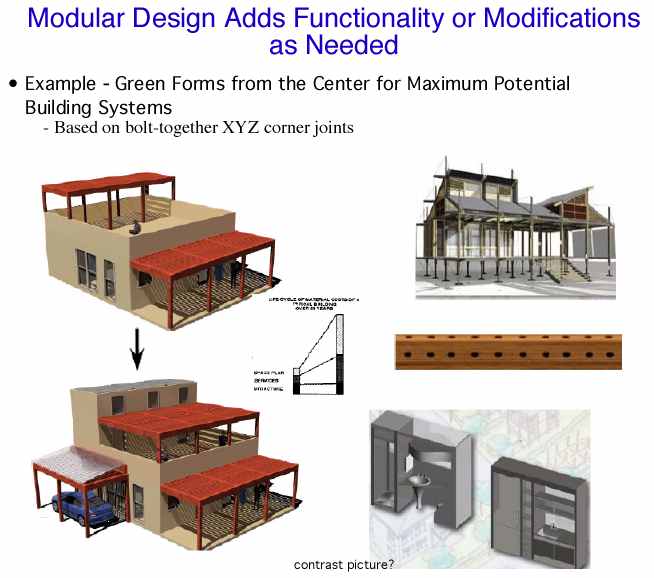

Center for Maximum Potential Building Systems

(By Marcin from a 2010 presentation)

Slide 1 - Slide 2 - Slide 3 - Slide 4 - Slide 5 - Slide 6 - Slide 7 - Slide 8 - Slide 9 - Slide 10 - Slide 11 - Slide 12 - Slide 13 - Slide 14 - Slide 15 - Slide 16 - Slide 17 - Slide 18 - Slide 19 - Slide 20 - Slide 21 - Slide 22 - Slide 23 - Slide 24 - Slide 25 - Slide 26 - Slide 27 - Slide 28 - Slide 29 - Slide 30 - Slide 31 - Slide 32 - Slide 33

Modular design is the second desirable feature of sound, lifetime design. Modular means that the object can be modified. This is particularly desirable, as needs change over a lifetime. The Center for Maximum Potential Building Systems in Texas has designed Green Forms – a modular building system based on xyz-corner bolted post and beam construction. A sample building beam with predrilled holes is shown. There are functional indoor modules, such as a bathroom or entertainment module, that can be fitted into the rooms.

It is important to note that lifecycle costs of products, such as buildings, occur mostly not in the original purchase price, but all the modifications that are made over the lifetime, as shown in the illegible graph in the middle. The up-front cost is about one third of the lifecycle cost. To keep the lifecycle costs down, modular design is desirable.

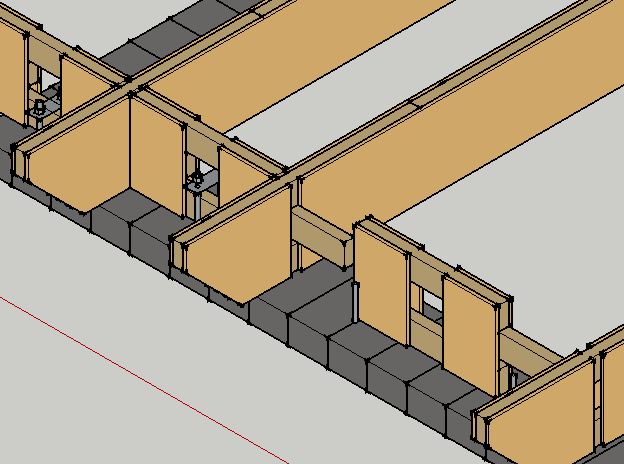

Modular CEB Construction OSE 2010

Modular truss design for CEB walls

Inspired mainly by Modular CEB Construction 2010 (where it could be used), but also on the constructed Microhouse 2013.

A modified version of 2010 OSE truss design (http://opensourceecology.org/wiki/Trusses#2010).

Basic materials needed are 2x4s, OSB sheets and nails.

The idea is to create easily extendible roof construction. In 2010 Modular CEB Construction the building could be extended by adding columns and then adding trusses one by one which would be much lighter than whole 32'x32' or 16'x16' module. If covered with corrugated steel it would require only to add next steel sheets.

This roof can be built on top of CEB walls as well as CEB columns and (with small modifications of strut) on wooden frame.

The idea is to make the assembly easy by fixing struts to joists and placing next truss and next struts. That would require no heavy equipment for lifting parts. The struts would be joined together by nailing trough OSB of one strut and 2x4 of the other (previous) strut.

The strut acts as a wall plate.

On the SketchUp drawing the roof is flat, but it can be easily tilted just as it is, or redesigned for certain roof angle. Current design is meant to be extendible only in length (roof width 16') but possibly also in width.

Sketchup file - File:OSE truss strut and wall plate in one.skp

./by Alan Hynek