D3D v19.04

Overview

- Builds on the D3D v19.02 3D printer.

Features

- Eco edition - insulated heatbed for 30%-60% lower energy consumption while printing with heated bed

- Upgraded to 24V control system

- Silent stepper drivers - uses TMC2208 in legacy mode instead of A4988

- 500W heatbed for 1 minute bed heatup time

- Added built-in GFCI electrical safety breaker as a standard feature

- Still uses the Titan Aero extruder with 3 mm nozzle

- Auto bed leveling with babystepping correction

Future Work

- Dual extruders borrowed from LulzBot TAZ Pro

- Supervolcano Nozzle add-on

- Rubber optimized extruder - see Rubber Extruder

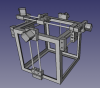

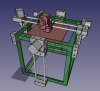

CAD

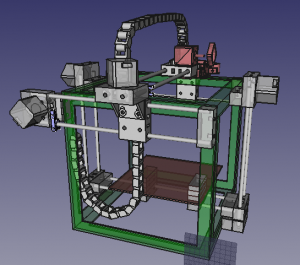

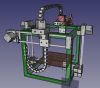

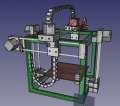

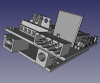

![]() Hint: Tasks: (1) Updating Y axis holding bracket including 3D printed Corner Fit. (2) New insulated bed. (3) 3D Printed Control Panel. (4) Offset cable chain start piece.

Hint: Tasks: (1) Updating Y axis holding bracket including 3D printed Corner Fit. (2) New insulated bed. (3) 3D Printed Control Panel. (4) Offset cable chain start piece.

CAD - Part Library

Printer

D3D v19.02 Final Assembly - size:nullkb - FreeCAD -File:D3Dfinalassemblyv1902.fcstd

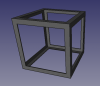

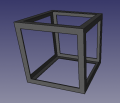

12" Frame - size:nullkb - FreeCAD -File:Frame1902.fcstd

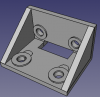

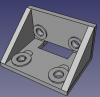

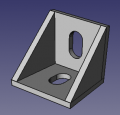

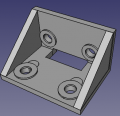

Bracket for bonding frame together without welding. - FreeCAD -File:Framebracket.fcstd. STL - File:Framebracket.stl

Z1 axis - size:nullkb - FreeCAD -File:Z1D3Dv1902.fcstd

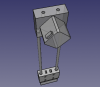

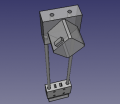

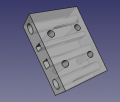

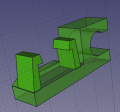

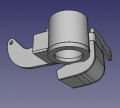

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

Universal axis carriage: File:Universal axis carriage side.fcstd. STL - File:Universal axis carriage side.stl

Half carriage: File:Axis half carriage.fcstd. STL - File:Axis half carriage.stl

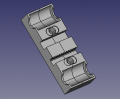

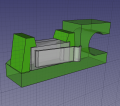

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

X cable chain - FreeCAD - File:X cable chain.fcstd.

X cable chain - FreeCAD - File:X cable chain.fcstd.

Y cable chain - FreeCAD - File:Y cable chain.fcstd.

Y cable chain - FreeCAD - File:Y cable chain.fcstd.

Cable chain bracket - FreeCAD - File:Cable chain bracket.fcstd.

Cable chain bracket - FreeCAD - File:Cable chain bracket.fcstd.

XY Bracket - FreeCAD - File:Xy bracket.fcstd. STL - File:Xy bracket.stl.

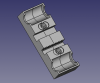

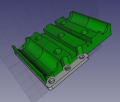

Cable Chain Main Link. File:Link.fcstd. STL - File:Link.stl

Cable Chain Main Link. File:Link.fcstd. STL - File:Link.stl

Beginning Cable Piece - File:D3dcablechain beginning.stl.

Beginning Cable Piece - File:D3dcablechain beginning.stl.

End Cable Piece - File:D3dcablechain end.fcstd. File:D3dcablechain end.stl.

End Cable Piece - File:D3dcablechain end.fcstd. File:D3dcablechain end.stl.

Endstop holder. - File:Endstopholder2.fcstd. File:Endstopholder2.stl. See Open Source Endstop Holder

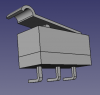

Generic limit switch. - File:Limitswitch.fcstd. Source: [1]

Endstop holder assembly. - File:Endstop assy.fcstd.

Y Cable Chain Mounting Bracket. - File:Cablechainbracket.fcstd. File:Cablechainbracket.stl.

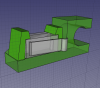

E3D Titan Bracket. - File:E3dtitanbracket.fcstd. File:E3dtitanbracket.stl.Source - [2]

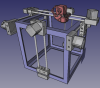

LFX_24V Power Supply - size:nullkb - FreeCAD -File:LFX 24V Power Supply.fcstd

Itemized:

- Frame

- Carriage

- Motor piece

- Idler piece

- Half-carriage with regular bearings

- Rods

- Extruder

- Endstop

- Heated Bed

- Cable chain start, simplified

- Cable chain end, simplified

- Cable chain link, simplified

- 18 mm bolt

- 30 mm bolt

- Angle for holding X to Y axis

- Controller - power supply - borrow from Lyman Filament Extruder

- Controller - Arduino

- Controller - RAMPS

- Controller - LCD screen - reverse engineer from drawing?

- Controller - MOSFET

Extruder

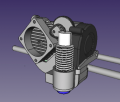

OSE Extruder v19.02 - File:Oseextruder1902.fcstd. Volcano version, tighter fit on carriage, auto Y alignment.

OSE Extruder nozzle assemby. Holds fan and sensor. File:Nozzleassembly.fcstd. STL - File:Nozzleassembly.stl

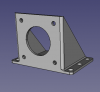

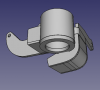

Stock Titan Aero mount bracket. See [3]. Bracket - [4] - STEP + STL. Check out drawings from E3D - [5]. STEP of Bracket - File:Bracket.fcstd

Titan Aero with motor - [6]

Titan Aero mount top plate. File:Brackettop.fcstd. STL - File:Brackettop.stl

Simplified carriage: File:Universal axis carriage side.fcstd. (From D3D Part Library)

8 mm sensor. Download - File:8mmsensor.fcstd

File:5015blower.fcstd 5015 Blower

File:40x10fan.fcstd 40x10mm fan

Control Panel

See more at 3D Printer Control Panel

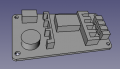

D3D v19.04 Power Supply - FreeCAD -File:Powersupply v1904.fcstd

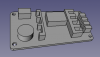

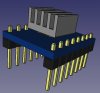

RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [7]

Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [8]

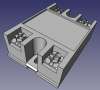

Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [9]. See Fotek SSR. Dimensions verified with Amazon source.

Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [10].

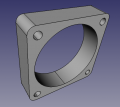

Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. Source at McMaster Carr: [11].

- Plug v1904.png

AC 2 prong plug - FreeCAD -File:Plug v1904.fcstd. Source -

- Legrand® Pass & Seymour® 15-Amp 125-Volt Black Plug

Working Doc

![[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl](/images/thumb/4/45/Motorside.jpg/120px-Motorside.jpg)

![[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.](/images/thumb/a/ae/Idlershort.jpg/120px-Idlershort.jpg)

![Generic limit switch. - File:Limitswitch.fcstd. Source: [1]](/images/thumb/2/2e/Limitswitch.png/120px-Limitswitch.png)

![E3D Titan Bracket. - File:E3dtitanbracket.fcstd. File:E3dtitanbracket.stl.Source - [2]](/images/thumb/7/79/E3dtitanbracket.png/120px-E3dtitanbracket.png)

![Stock Titan Aero mount bracket. See [3]. Bracket - [4] - STEP + STL. Check out drawings from E3D - [5]. STEP of Bracket - File:Bracket.fcstd](/images/thumb/5/51/Titanstockholder.jpg/120px-Titanstockholder.jpg)

![Titan Aero with motor - [6]](/images/thumb/7/78/Titanwithmotor.png/120px-Titanwithmotor.png)

![RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [7]](/images/thumb/a/a5/RAMPS14_v1904.png/120px-RAMPS14_v1904.png)

![Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [8]](/images/thumb/a/a8/Stepperdriver_v1904.png/120px-Stepperdriver_v1904.png)

![Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [9]. See Fotek SSR. Dimensions verified with Amazon source.](/images/thumb/b/ba/Ssr_v1904.png/120px-Ssr_v1904.png)

![Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [10].](/images/thumb/f/fe/Smartcontroller_v1904.png/120px-Smartcontroller_v1904.png)

![Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. Source at McMaster Carr: [11].](/images/thumb/5/50/Gfci_v1904.png/117px-Gfci_v1904.png)