German Log

![]() Status - Done: Note also Felix Makori Log To Do: Blocks:

Status - Done: Note also Felix Makori Log To Do: Blocks:

Tractor Construction Set 2017. Power Cube v17.08. Development Team Log.

OSE Hangout Jitsi Meetup. OSE Network.

Wiki Instructions. Wiki Formatting Help.

German's User Page

Fundamentals

Timesheet

3D Printer: all links

- 3D Printer Genealogy

- D3D Australia

- Chile D3D

- D3D v19.04

- D3D

- D3D BOM

- D3D Part Library

- D3D Performance Log

- D3D Integration

- 3D Printer Construction Set Workshop

- D3D Instructional videos for April, 29th,2017 Workshop

- 3D Printer Construction Set Workshop August 12, 2017

- Design sprint from August 2017

- D3D Controller (RAMPS wiring, code, machine control)

- D3D Language Agnostic Instructionals

- 3D Printer Bed Leveling

- 3D Printer Development

- D3D 1612 Product Testing

- Differentially_Heated_HBP

Other links of interest

Slides twelve-week plan D3D Printer

BOM D3D Australia

BOM D3D Argentina

Log

Sun Feb 11, 2018

- Printed the first set of short idler side parts for the D3D printer. Prints are aesthetically acceptable and the dimensions are accurate.

- Worked on D3D Australia log.

See D3D Australia for more details.

3 Hours

Fri Feb 09, 2018

- Printed a few more test models. Prints are of acceptable quality. Dimensions are accurate. Some more refining can be achieved.

- I had to reinstall Cura LulzBot Edition but only managed to find Version 2.6.66 which has a different interface to the version I had become familiar with, although it offers a wider variety of options to tweak the prints.

- Solved issues with squashed bottom layers.

- There is a fair bit of shadow/ripple/ghosting on the printed pieces that need to be reduced.

See D3D Australia for more details.

6 Hours

Tue Feb 06, 2018

- Finished geometry rearrangement on D3D printer.

- Printed test models.

- Worked on resolving some issues.

See D3D Australia for more details.

5 Hours

Sun Feb 04, 2018

- Worked on D3D Australia log.

2 Hours

Fri Feb 02, 2018

- 3d printer assembly. Rearranged X-axis, PSU, HBP and control board to suit OSE's standard geometry for D3D 3D printer.

I would recommend placing the installation of the Z-axis and HBP as the absolute last step in the assembly process. This at least until an accurate, standardized, position for the holes on the frame can be established.

6 Hours

Tue Jan 30, 2018

- Test printing. Changed the steps per millimeter configuration on the z-axis.

- Printed a quick fix to add mechanical strength to the HBP support and keep the sandwich closed tight around the rods.

See D3D Australia

4 Hours

Wed Jan 24, 2018

- First day of test-printing and the machine performs very well considering where we come from. A few details need attention to improve the quality of the prints.

- Solved yesterday's issue with three-point probing. For some reason, the GCode in Cura had changed.

- Worked on D3D Australia log.

See D3D Australia

6 Hours

Tue Jan 23, 2018

- Worked on Marlin firmware values for probing points, travel limits after homing and extruder offset. I struggled to find a physical reference to match with what the values in the firmware where indication. The imaginary +X of the cartesian coordinates on the HBP is inverted, that is, it increases in value to the left. See details on D3D Australia

6 Hours

Mon Jan 22, 2018

- Worked on Marlin firmware. Half-succeeded at getting the Z-probe to stay within the boundaries of the HBP.

- Set the machine to print a cube in mid-air, without filament. It worked twice, then I had issues that I believe are related to the firmware. I must have accidentally changed something.

- Worked on D3D Australia log and the Troubleshooting section of the Product Manual where I added a table.

5 Hours

Fri Jan 19, 2018

- Troubleshooting yesterday's problems. All day.

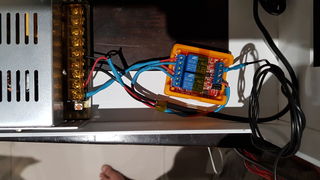

- Issues getting the motors to move. After exchanging some emails with Roberto and Marcin, and a fair bit of googling, some of these problems where solved. A couple of things remain unresolved. Heating of HBP is one of them. Relay module is on standby but there seems to be an issue with the activation signal from RAMPS.

- Worked on D3D Australia.

Working on the Troubleshooting section of the Product Manual page.

6 Hours

Thu Jan 18, 2018

- Finished design and printed alternative to cable chain.

- Finished routing wires.

- Watched Devs meeting video from Tuesday, Jan 9.

- Worked on uploading Marlin firmware to Arduino and tried to set up the printer. Issues arose:

- X and Y axes move freely by hand but are not working when powered using the control panel in Cura. The motors receive power but instead of moving one way or another they are locked in place.

- There is a lot of vibration on the belt of the Z-axis on the side where the peg holds the belt to the carriage. One can also hear a noise. This happens while manually operating the axis using the printer control panel in Cura. The interesting thing is that if I use the bed leveling function from the top menu, the noise and vibration disappear. Also, the actual range of movement of the bed is much larger than the indicated values on the screen: if I send a signal to move it by 0.2mm, it actually moves like 5 whole millimeters instead.

- The relay module is being constantly powered by the RAMPS and the heated bed heats up to max temp all the time. I tried swapping the cable to the minus (-) connector on D8 but both terminals (+ and -) seem to be powered all the time.

Followed guidelines from Product Testing in this wiki.

6 Hours

Wed Jan 17, 2018

- Routing wires in the machine.

- Design of alternative to cable chain for X-axis wiring

- Read about connections on RAMPS and Arduino.

- Visited some local shops searching for a missing heatsink for one of the Pololu drivers. Purchased 1.5 meters of plastic spiral wrap.

6 Hours

Fri Jan 12, 2018

- Glued heated bed to the holder and attached it to the carriage on the Z-axis.

- Routed HBP power wires to relay module and PSU.

- Wired and installed relay module.

- Designed and printed insulating box for relay module.

- Edited D3D Australia log.

5 Hours

Tue Jan 09, 2018

- Glued rubber spacers to HBP.

- Glued PEI film to HBP.

- Glued magnets to PSU and intalled it on the frame.

- Studied details concerning the wiring

- Started the design of an insulating box for the relay moduke.

5 Hours

Mon Jan 08, 2018

- Cut heat-resistant rubber to use as a spacer between heated bed and bed rods.

- Rearranged end stops to shorten the length of travel on Y and lengthen it on X.

- Installed step motor controllers on RAMPS board.

- Adjusted X-axis so it is parallel to frame.

3 Hours

Sat Jan 06, 2018

- Grouped the controller-end of the extruder and heated bed termistors in a single PHR-4 connector.

- Installed sensor holder on extruder.

- Marked on the frame the range of movement available on the X and Y axes to have an idea of the printable area's size and position.

- Worked on D3D Australia Log

4 Hours

Wed Jan 03, 2018

- Trimmed 2mm from M6x30 SS screws.

- Generated .stl and .gcode files and printed belt pegs.

- Finished the assembly and attached X and Y axes to frame.

Belt tensioning mechanism works great.

Issues to resolve

- With the current configuration, the X axis has a total travel of 191mm (7 1/2 in). Moving the end stop further towards Y2 on the X axis could increase this travel by 12mm (1/2 in).

- At the moment, the Z-axis sits 20mm offset towards Y2 in relation to the center of travel of the carriage on the X-axis' (center of bed on X).

3 Hours

Tue Jan 02, 218

- Affixed stepper motors to axes assemblies.

- Bought the twelve M6x30mm screws that needed to affix the axes to the frame and attached the Z-axis.

- Looked for references on the orientation of the motor terminals. I will go with the Y-axes diagonally down and back, X-axis and Z-axis diagonally up and left (towards Y1).

- Cut belts lengths.

I think that the instructions for the assembly of the axes can be made simpler in writing. Also, I need to work on a checklist for each step of the assembly.

3 Hours

Mon Jan 01, 2018

- Worked on the wiring of the controller. Changed the sequence of the wires on a PHR-4 terminal and soldered the wires of the Dupont connector from the extra end stop to the inductive sensor's wires. Connected the cables for all the axes, end stops, Z probe and extruder motor to the controller,

- Looked for details on setting up the relay module for the HBP.

- Worked on D3D Australia Log.

Some doubts

Tried to figure out some details about the wiring of the relay to feed power to the HBP. After a few hours of watching videos and reading some specifications about relays and MOSFETs, this is part of what I believe is correct:

- What I have is a 2 channel relay module, which is not the same than a MOSFET.

- I will split the positive wire going to the HBP and connect it to one of the relays. Let's say relay 1. I will connect one of the split ends of the wire to the NO1 position and the other one to the COM1. This means that while the coil of the relay is not energized, there will be no power going to the HBP.

- I will connect a pair of wires carrying 12V, coming directly from the PSU, to the DC+ and DC- terminals of the relay module.

Questions are:

- Where am I getting the signal to activate the relay from? I believe that I have to connect whatever single wire coming in from somewhere to the IN1 terminal of the module. Is that one wire coming from one of the terminals on the D8 position of the controller? Is it the + or - wire? And,

- Do I need to reset the jumpers on S1 and S2. At the moment the configuration is High-Com for both.

- On the extruder motor, the PHR-6 connector: Is the color sequence of the wires the same than for the rest of the stepper motors?

5 Hours

Sun Dec 31, 2017

- Worked on D3D Australia log.

- Worked on the wiring of the controller.

2 Hours

Sat Dec 30, 2017

- Soldered wires to HBP. This took some time since the 25-watt soldering iron that I have was not powerful enough to do the job. Tested the heated bed by connecting it directly to the power supply. The maximum temperature reached was 105 deg centigrades.

- Deburred some of the 3D printed parts (bridged filaments from magnet and nut/screw sockets) and assembled axes y and x.

- Installed pulleys on stepper motors.

- Worked on D3D Australia log.

5 Hours

Thu Dec 28, 2017

- Modified the .stl, created .gcode and printed: sensor holder, end stop interfaces and flanges for idler bearings.

- Glued magnets to x-axis carriage and extruder motor interface.

- Worked on some ideas for the HBP. I am not going to be using a second z-axis at this stage.

3 Hours

Wed Dec 27, 2017

- Drilled and redrilled holes in the metal frame.

- Put together one of the axes assemblies and test fitted it to the z-axis and y-axes holes to check for alignment, spacing and freedom of movement of the carriage.

- The bearings for the idlers that I received do not have flanges. I will 3D print a set of washers that will reduce the friction of the belt against the sides of the bearings' receptacle on the short idler side.

- Worked on D3D Australia log.

4 Hours

Tue Dec 26, 2017

- Modified the template to place the holes on the frame and created spacers to separate the axes assemblies from the frame. Inbuild separation is 2mm. Printed and test fitted.

- Worked on D3D Australia log.

4 Hours

Sat Dec 23, 2017

- Assembled the carriages for the four axes (15 min per carriage). Glued magnets to x-axis carriage.

- Finished holes-template and tried it on frame. It is a perfect fit but, unfortunately, I miscalculated the position of the holes. I will have to modify it and print it again. See the images of the printed template at D3D Australia.

4 Hours

Fri Dec 22, 2017

Started working on a printable template to mark the placement of the holes on the metal frame of OSE's printer.

4 Hours

Wed Dec 20, 2017

- Finished welding frame and painted it (3.5 hours). Uploaded photos to D3D Australia.

- Created and embedded the following video:

4.5 Hours

Tue Dec 19, 2017

The 3D printed parts with the brim are pretty much perfect. Removed brim and assembled two carriages. They slide with no resistance on the shafts. Started cleaning the frame for painting and the epoxy glue started cracking in parts and separating from the frame in others. Used a ZAP brand clear epoxy. I am not sure about the reasons but it could be a combination of factors. I disassembled the cube and started from scratch. This time I decided to weld it with a TIG machine. Only tack weld it at this point.

4 Hours

Mon Dec 18, 2017

Due diligence. D3D Australia Log. First set of Carriage Side Parts was printed. Lots of warping due to printer settings. Assembled and tried the parts. I will need to print them again. Created new .gcode file and started printing another set. More details here D3D Australia

2 Hours.

Sun Dec 17, 2017

Due diligence. Logs. Started D3D Australia log.

2 Hours

Sat Dec 16, 2017

Glued the last square to the frame and trimmed excess epoxy (+-1 hour). Printed second set of Motor Side assembly. Due diligence: watched Devs meeting video from Nov 14th.

3 Hours

Fri Dec 15, 2017

Short Iddler Side printed successfully. Created .gcode file and started printing another set of parts (Motor Side). Preparing (straightening bows, sanding of edges, degreasing), squaring and gluing of 16" D3D frame (+-4 hours). Put together some of axes parts to check the squareness of the 8mm rods. Prints are very precise. Rods are parallel across all planes. Assembled HBP support. Possible issues could be sagging of the far end of the heated bed after some use and jittering of bed if Z-axis needs to work too hard for the auto leveling during the printing. br> 5 Hours

Thu Dec 14, 2017

First set of parts printed with a fault (shift on Y-axis position halfway through the printing process). Checked motor driver. Swapped X-axis driver with Y-axis driver. The problem seems to be solved. Probably just a bad contact in the driver's connection. Created .gcode file for Extruder Holder. Extruder holder printed successfully. Created .gcode file for Short Idler Side. And started the printing process. Revisited some links that relate to the final assembly of the axes and printer. Looked at details for HBP holder.

5 Hours.

Wed Dec 13, 2017

Received 3D printer, assembled it and started the process of familiarization. Due diligence. Solved some issues (bed leveling and Y-axis motor driver). Familiarization with Cura, .gcode files and setting up printer parameters for PLA plastic. Printed test model and started first set of parts for OSE's D3D.

5 Hours

Tue Dec 12, 2017

Due diligence. Familiarization with HBP. Levelling and heating systems. Read through details on D3D Marlin, slides and associated links.

Completed order for new frames.

2 Hours

Mond Dec 11, 2017

Tried different positions for each cut frame to see if I could get a reasonable square cube but I am not happy with the gaps along edges. I have returned the cuts to the engineering shop and re-ordered the frames from another place that uses a laser CNC table. Hope to have the parts by next week. I am now a week behind schedule on the 12-week plan.

3 Hours

Sun Dec 10, 2017

Created hole templates to drill 3D printer frames. Made squaring aids with 30mmx30mm square box profile and worked on assembling the 3D printer's frame, but fail to glue the parts together. The cuts made by the plasma CNC machine at the engineering shop had to much angular error and the frames were not square.

5 Hours

Mon Nov 27, 2017

Due diligence. More reading. Purchased epoxy glue from a local store. Ordered relay for HBP.

2 Hours.

Sun Nov 26, 2017

Due diligence. Tracking the 3D printer parts that are still missing (bearings). Work on slides. Familiarization with heated bed specs and different ways of leveling. Ordered stepper motor cables from local supplier.

4 Hours

Thu Nov 23, 2017

Due diligence. Watched OSE Dev meeting video from this week. 1 Hour

Wed Nov 22, 2017

Due diligence. There are two or three friends that might give me a hand putting together a BOM in Argentina. I have embedded the spreadsheet in this log. Parts keep arriving.

2 Hours

Mon Nov 20, 2017

Due diligence. Edited twelve-week plan slide. Found more links related to D3D in the Wiki.

2 Hours

Sun Nov 19, 2017

Due diligence. Edited twelve-week plan slide. Updated Australian BOM.

2 Hours

Tue Nov 14, 2017

Due diligence. Watched developers meeting from Nov 7th. Parts for the printer are trickling in. Received power supply but it arrived damaged (from Australian supplier). Trying to get in touch to swap for a good one. More quotes requests sent and received for 3D printed parts; prices are too high. More reading about defects during printing of parts.

Start of stage 2 of the twelve-week plan: "Week 4 to 6. Building the printer and completing CBM (Complete Build Manual)."

4 Hours

Mon Nov 13, 2017

End of stage 1 of the twelve-week plan: "Week 1 to 3. Familiarization with concepts and model. Order materials. Update BOM for local vendors. Work on a Complete Build Manual."

On track.

Sun Nov 12, 2017

Due diligence. Familiarization with printing materials and print defects during the printing process. Watched part of some of the developer's meetings videos from earlier this year looking for references with details about the D3D printer model.

4 Hours

Sat Nov 11, 2017

Due diligence. Familiarization with the generation of .stl files and handling of the same files in slicing software (Cura). Sent quote requests to several 3D-printed parts providers.

4 Hours

Thu Nov 09, 2017

Cut 8mm rods to length, squared the ends with a lathe and straighten a very small curve that formed in them probably due to transportation. Updated Australian BOM.

2 Hours

Wed Nov 08, 2017

Toured the town searching for some of the last items on the list. Updated Australian BOM.

3.5 Hours

Tue Nov 07, 2017

Unable to download or share .dxf file File:D3dframe layout.dxf. Created FreeCAD 3D model of one side of the main frame and generated a basic dimensional drawing. Sent emails to get quotes for the 16" frame. Ten emails were sent, including to three local engineering shops.

File:Frame16Single.fcstd

File:Frame16Single.pdf

3 Hours

Sun Nov 05, 2017

More work on Australian BOM for D3D Printer. Ordering parts. I would like to test the magnets when they arrive to have a precise idea of the weight they can actually carry. Watched developers meeting from Oct 24th.

4 Hours

Sat Nov 04, 2017

Looking for local vendors, Australian BOM for D3D Printer. Ordering parts. Due diligence: understanding specifications of parts to order the correct ones from alternative sources. Compromise between prices, shipping costs and shipping times. The paradox of choice.

5 Hours

Sun Oct 29, 2017

As I read through the piled up information related to the D3D printer, I keep drifting away from the main objective of this twelve-weeks plan, this mainly due to the lack of knowledge on the subject. The learning process consumes most of my time at the moment.

Embedded a copy of the August 12, 2017: RAMPS version of BOM to this log. I haven't yet made changes to it.

5 Hours

Sat Oct 28, 2017

Twelve-week D3D build plan.

4 Hours

Fri Oct 27, 2017

Working on finding local vendors in Australia for the parts in the BOM. I think that many of the parts will be sourced from current vendor links since most of these parts are substantially more expensive here.

4 Hours

Tue Oct 24, 2017

Kept at chasing links related to D3D printing development. List of parts, assembly, BOM, etc. Worked on a slide to outline a 12-week plan to put together a prototype here in Australia and evaluate the chances of at least gathering the parts in Argentina to build another machine over there.

See slides under title: 3D Printer: all links.

3 Hours

Sun Oct 22, 2017

Made an attempt to track all links related to D3D printing spread around OSE Wiki. I found this to be a time-consuming task, in part because I did not participate in the R&D process. Nevertheless, I believe that this information should be better organized to facilitate accessibility to all newcomers and those wanting to learn the basis of each development. This could also be related to my lack of overall familiarity with the way logs are kept. This exercise was still useful to learn several details associated to the D3D printing project.

2 Hours

Thu Oct 19, 2017

Watched some more free CAD tutorials and revisited Roberto's video several times. Phone talk with Marcin. Started putting together a twelve-week plan to build the 16" 3D printer here in Australia.

2 Hours

Wed Oct 18, 2017

Went through some more of the meetings and added minutes in a comment for the meeting of Wed Sep 27, 2017. Just by accident learned that YouTube automatically creates links for the time format 00:00:00 so one can create a sort of time index where different topics can be easily found within the video. This was a personal exercise in an attempt to keep track of the topics being discussed, but I think we should look at making it a standard addition to the videos. e.g.

3 Hours

Mon Oct 16, 2017

I've been catching up with what has been going on in the past four weeks. Watched recorded meetings and have a read throughout the slides and notes.

Ran new Linux live version (0.45) on an older computer. Everything seems to be in order. Booting up takes a long time, between 6 and 6.5 minutes.

5 Hours

Fri Sep 08, 2017

- Watched Aug 29 meeting video once again. Watched Sep 05 meeting video. I'm starting to find my bearings.

Important information from meetings is easy to overlook when one is not familiar with the details of what is going on and have to deal with many new concepts and tools.

Going to the supermarket to buy a notepad (handy for when I watch the videos on devices other than my laptop).

Left the Sep 05 meeting video halfway through thinking that I knew where to go and that it was going to be easy to find, but encountered the same issue as I did many times before: got lost in the Wiki. It reminds me, somehow, to those neighborhoods where the streets are not straight and one ends many times in some cul de sac.

- Added a link to the Tractor Construction Set 2017 and to the Power Cube v17.08 to this log.

- Started working on the Master CAD file for the Micro Tractor this evening. I managed to put the four holes to support the motors on the brackets but I think the large bore has to be reduced in order to have more material between the edge of the bore and the orifices for the bolts.

- Uploaded a new file for the motor brackets with the four holes to attach the motor. Not sure whether that is ok but I put it there just in case.

- I struggle with the constraint of parts in the assembly 2 workbench. I still don't know how to get one part or the other to stay in its place.

- I cannot preview my edits in the Wiki. I always have to save in order to view changes.

5 Hours

Wed Aug 30, 2017

Watched this week's meeting video and read notes.

Burned new ISO file to USB but still unable to run Ubuntu from it. See previous log entry. IT suggests that this issue is associated with a safety feature in the BIOS configuration when using some versions of Windows OS. Mine is Win 10 Home.

1.5 Hours

Mon Aug 28, 2017

Google Hangouts 101

Another Failed attempt to run Ubuntu from USB drive.

- Version of the OSE Linux ose0.4.3.iso [1]

- Metabox Laptop

- Intel Core i7-6700HQ Processor (6M Cache up to 3.50 GHz)

- 32GB DDR4 2400MHZ (2 x 16GB)

- Windows 10 Home

1.5 Hours

Sun Aug 27, 2017

Finished new developer to-do list.

OSE crash course.

Went through Wiki instructions and daily log of tasks.

Watched some of the proyects short videos.

4.5 Hours

Sat Aug 26, 2017

New developer to-do list.

2.5 Hours

Fri Aug 25, 2017

Continued New Developer Orientation

0.5 Hours

Thu Aug 24, 2017

Started New Developer Orientation

Familiarization with Wiki

2.7 Hours

Sun Aug 20, 2017

Uploaded the FreeCAD file and embedded the cube video to the work log.

1.5 Hours

Sat Aug 19, 2017

Managed to produce 30-second video with Kdenlive.

5 Hours.

Fri Aug 18, 2017

Still fighting Kdenlive. Cannot figure out how to speed up video to such a short length. Tried several methods but the rendering of the file produces an undesired outcome.

4 Hours

Thu Aug 17, 2017

Finished cube and Vokoscreen capture.

0.75 Hours

First attempt at understanding Kdenlive. Struggle.

3 Hours.

Wed Aug 16, 2017

First attempt to record the whole process of building the cube. Computer froze two hours into the work. Had not been saving the progress. Vokoscreen video and cube file lost. Started over and got to the stage of sketching my initials. Saved and closed files to continue following day.

3.5 Hours.

Tue Aug 15, 2017

Still trying to piece this cube together

3 Hours

First try at recording with Vokoscreen.

0.25 Hours

Mon Aug 14, 2017

FreeCAD

2 Hours

Sun Aug 13, 2017

FreeCAD Encountered some troubles trying to fit the nut to the bolt. Not familiar with what ISOs are a match between the fasteners. Also, the Screw Hole Calculator says that a M30 screw should fit a hole of 26.5 mm but if I measure the M30 bolt with the ruler it says 29.91 mm approx. I do not know how to understand this discrepancy at the moment.

6 Hours

Sat Aug 12, 2017

Another long afternoon in front of the computer with FreeCAD. It has been very frustrating at times. It reminds me of the days in which I wanted to format a letter in MSWord and had no clue on how to do it. Things are intuitive, but not so.

- Learned some characteristics of the Sketcher workbench and how to toggle between workbenches to access the tools needed for differents parts of the job.

- Encountered a problem that I have not been able to solve yet. When I try to sink or stretch my sketch on the face of one of the tubes a dialog box appears saying that the shape is not perfect or that it's not closed (need to investigate). The program also freezes for a couple of minutes.

5 Hours

Fri Aug 11, 2017

FreeCAD

- Spend many hours in the afternoon of this day trying to find my way around different commands of the software.

- Imported the eight hole tubes from the library. Learned to copy and paste the eight hole tubes and how to move them away from the original so they are visible.

- Learned to activate the different objects (layers) and in which order to apply some of the commands.

6 Hours

Sun Aug 06, 2017

Created work log page.

1 Hour

- Downloaded .iso file 04-28-17ose0.42

- Burned ISO to USB drive using Rufus. Booting successful but after selecting "Try Ubuntu without installing" or any other command the machine froze on a black screen. Burned a second time but still no luck.

- Burned ISO using YUMI. Booting successful but after selecting "Try Ubuntu without installing" or any other command the machine froze on a black screen.

- Burned ISo using Universal USB installer. Booting successful but after selecting "Try Ubuntu without installing" or any other command the machine froze on a black screen.

- Installed Virtual Box and created a virtual machine. Ubuntu runs now, apparently seamlessly, in parallel with Windows 10.

6 Hours

Tue Aug 01, 2017

- Account request approved.

- Accessed account to check log in process.

Sun Jul 30, 2017

- OSE account request.

- Email address confirmation.