Steam Engine Intro: Difference between revisions

(Moved letters and emails to Steam Engine/Correspondence) |

m (Text replace - "openfarmtech.org/weblog" to "blog.opensourceecology.org") |

||

| (64 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{breadcrumb|Energy|Steam Engine}} | ||

see {{Steam Engine}} | |||

=Description= | = Description = | ||

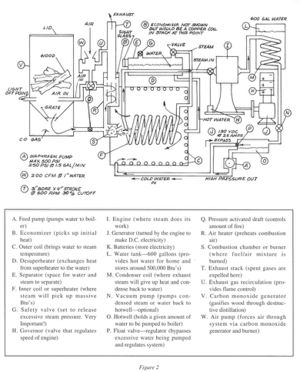

We are proposing an open source steam engine project, to deliver | [[Image:Integrated_Energy_System.jpeg|thumb|Complete steam engine system.]] | ||

We are proposing an open-source steam engine project, to deliver a highly-efficient modern steam engine with the following features: | |||

* Scalable power from 5 to 100 horsepower | * Scalable power from 5 to 100 horsepower | ||

* Modular design for easy building, maintenance, and repair | * Modular design for easy building, maintenance, and repair | ||

* Simple | * Simple uniflow design - steam flows in a single direction from input valves to exhaust port(s) | ||

* Modular crankshaft design to allow additional units to be added | * Modular crankshaft design to allow additional units to be added | ||

| Line 19: | Line 21: | ||

* Easy to troubleshoot and repair | * Easy to troubleshoot and repair | ||

'''Reading About Steam Engines''' | |||

Steam power is not taught in general. To master this topic, you should consider having a look at the information in [[Steam Engine Research/Books]] Tom Kimmel, of Kimmel Steam Power has some good material [http://www.kimmelsteampower.com/] as does Mike Brown in a reading list [http://www.mikebrownsolutions.com/order.htm]. Description of this system by author and excellent background info on home power steam [http://www.fastonline.org/CD3WD_40/JF/JF_OTHER/BIG/Reciprocating%20Steam%20Engine.pdf]. Skip Goebel has thoughts on an electronically controlled steam engine taken from [http://www.mail-archive.com/sustainablelorgbiofuel@sustainablelists.org/msg01818.html]. | |||

= | == Additional Information == | ||

* '''[[:Category: Steam Engine]]''' | |||

* '''[[Steam Engine/Index]]''' - steam engine pages organized by topic. | |||

* '''[http://blog.opensourceecology.org/category/global-village-construction-set/steam-engine-construction-set/ Blog post and interview with Harry Schoell]''' | |||

* '''[http://blog.opensourceecology.org/forum/steam-engine-construction-set/ Related Forum]''' - discussion forum. | |||

* '''[[Steam Engine/Correspondence]]''' - reviews, messages, letters,etc. | |||

* '''[[Steam Engine/Terminology]]''' - terms, jargon, abbreviations, etc. | |||

* '''[[Steam Engine/Things To Do]]''' | |||

* '''[[Steam Engine/Others]]''' - Links to commercially available steam engines, plans, other projects, etc. | |||

= Project Team = | |||

OSE: | |||

* Marcin Jakubowski, Visionary | |||

* Mark Norton, Project Manager | |||

* Andrew Buck, Simulations, CAD | |||

* Josh Jordan, Electronics and Sensors | |||

Design Reviewers: | |||

* Tom Kimmel, SACA | |||

* Ken Helmick, SACA | |||

* Harry Schoell, Cyclone Tech. ?? | |||

Additional Input: | |||

* Ron Whaley, PKI Alumnus (White Cliffs Solar Project) | |||

== Joining the Steam Engine Team== | |||

OSE policies on GVCS projects specify that only active, contributing people are considered part of the project team. While we are always looking for people to help out, we need people who are committed to making real contributions. We do not need people who want to talk about building steam engines, we need people who want to design and actually build them. If you are such a person, please fill out the [[Team Culturing Survey]] and get yourself set up with accounts on the forum and wiki. All Steam Engine documentation is publicly posted on the OSE wiki. | |||

After joining OSE, have a look at [[Steam Engine/Things To Do]] and the Steam Engine Pivotal Project [https://www.pivotaltracker.com/projects/300681#]. Pivotal is a project management tool that allows us to track tasks that need to be done. Figure out what you are interested and what matches your skills and experiences. Then get in touch with the Steam Engine Project Manager (Mark Norton - markjnorton (at) earthlink (dot) net). | |||

You will be given one or two tasks to complete before being invited as a full project participant. To some degree, this is a test of your commitment. More than that, it is a way of building trust in your ability to make a meaningful contribution. OSE GVCS Project teams are deliberately lean and agile. The pace can be fast at times and we need you to adapt to the current rate of development. | |||

= Design Rationale = | |||

[ | Although it is a matter of some debate, there are many who feel that our global civilization has past the (so called) point of peak oil. Peak oil [http://en.wikipedia.org/wiki/Peak_oil] refers to the point in time when easy sources of petroleum have been exhausted. Past that point, demand continues to rise (largely pegged to global population growth) but production rolls off. If we accept that we have past the point of peak oil, then how will we maintain civilization's need for energy? While part of the answer lies in reducing consumption, a bigger part lies in alternative sources of energy. The Open Source Ecology project is exploring a number of [[:Category:Energy | alternative energy sources]]. Given reliable energy sources, the Open Source Steam engine can be used to convert steam energy into motion (and thence into electricity, etc). | ||

Steam engines have a number of benefits over other kinds of motive power: | |||

* Relatively uncomplicated, few moving parts (compared to other engines) | |||

* Driven by steam, produced in a variety of ways (boiler, solar concentrator, geothermal, etc.) | |||

* Can be made modular: steam source, controller, cylinder, crankshaft | |||

* Scalable power: connect more steam engine units onto a common crankshaft | |||

* Easy to build: most parts can be fabricated from stock materials | |||

Additional reasons to design and build an open source steam engine include: | |||

* Relevant as an appropriate technology choice in both poor and rich countries when coupled to flash steam generators | |||

* Basis for another kind of [[Power Cube]] | |||

* May be coupled directly to linear hydraulic pump (feasibility study required) | |||

* | |||

* | |||

= Design = | |||

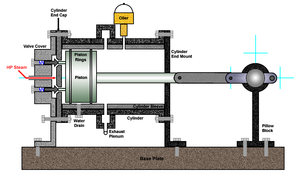

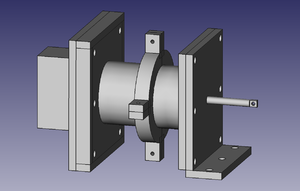

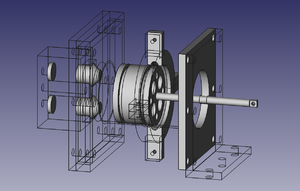

[[Image: | [[Image:Design-7-A.png|thumb|right|Current Design]] | ||

[[Image:Steam Engine CAD Render.png|thumb|right|Current Design - CAD Model]] | |||

[[Image:Steam Engine CAD Render (Cutaway).png|thumb|right|Current Design - CAD Model, internal components.]] | |||

Overall design of the Open Source Steam Engine breaks down like this: | |||

* Existing and Historic Designs | |||

** [[Steam Engine Design/Historic]] | |||

** [[Steam Engine Design/White Cliffs]] | |||

** [[Steam Engine Design/White Cliffs Report]] | |||

* OSE Engine Designs | |||

** [[Steam Engine Design/2009]] - an older design attempt | |||

** [[Steam Engine Design]] - current design description | |||

** [[Steam Engine Design/Solenoid]] - a future design | |||

** [[Steam Engine Design/Valves]] - notes on different kinds of valves | |||

* Steam Generator Designs | |||

** [[Steam Engine Design/Boiler]] | |||

** [[Solar Fire]] | |||

= | == Summary of Proposed Design == | ||

The current OSE Modern Steam Engine is based on design developed for the White Cliffs solar power station in NSW, Australia (see [[Steam Engine Design/White Cliffs]]). While the White Cliffs engine used a converted diesel engine, the essential concept is the same: a uniflow steam engine using a bump valve control mechanism. Our engine is greatly simplified from the White Cliffs design. Initially, it will be a single cylinder (scalable by adding more to a common crankshaft) driven by steam from a boiler or solar concentrator (such as [[Solar Fire]]). Two bump valves are activated by valve pins mounted on the face of the piston head. Just before top dead center of the cycle, the bump the steam valves open, letting new steam into the cylinder. A flywheel carries the piston past top dead center and at the cut-off point, the steam valves close. Expanding pressure causes the piston to move down the cylinder until it nears bottom dead center, at which point the piston uncovers four exhaust vents allows steam (any any condensed water) to escape the engine. An exhaust plenum is provided to capture spent steam so that it might be used for other purposes (like heating). | |||

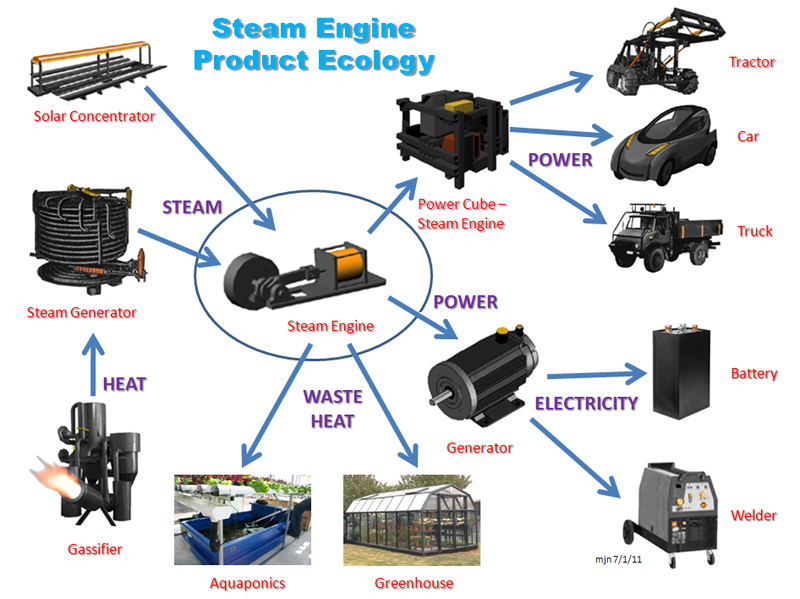

= Product Ecology = | |||

[[Image:Steam-Engine-Product-Ecology.png]] | |||

The steam engine gets inputs from: | |||

* [[Solar Concentrator]], [[Solar Fire]] | |||

* [[Steam Generator]] | |||

* Gassifier | |||

and provides power to: | |||

* [[Power Cube]] - Steam Engine version | |||

* [[Tractor]] | |||

* [[Open Source Car]] | |||

* Truck | |||

* [[Electric Generator]] | |||

* [[Open Source Welder]] | |||

* [[Aquaponics]] | |||

* [[Greenhouse]] | |||

= Specifications = | |||

Inch to millimeter conversion chart [http://mdmetric.com/tech/cvtcht.htm]. | |||

Specifications including dimensions are provided in [[Steam Engine Specifications]] and complete building instructions are given in [[Steam Engine Build Instructions]]. Sourcing of parts is specified in [[Steam Engine Bill of Materials]]. | |||

= Costs = | |||

(Cost estimates go here) | |||

= Additional Links = | |||

* Biomass CHP with steam engine - [http://www.pritchardpower.com.au/] | |||

* 60% vapor cycle efficiency in steam engine power plant? - [[http://www.lesa-maschinen.de/cms/index.php?page=technologie&hl=en_EN]] | |||

* $300/hp steam engines in production, Peru - [http://www.sensiblesteamperu.com/index_archivos/Page581.htm] | |||

== Steam Engine History == | |||

Steam Engine | * [http://www.egr.msu.edu/~lira/supp/steam/ Brief History of the Steam Engine] | ||

* [http://campus.udayton.edu/~hume/Steam/steam.htm The Steam Engine] | |||

* A History of the Growth of the Steam Engine: [http://books.google.com/books?hl=en&id=YiNMAAAAMAAJ&dq=steam+engine&printsec=frontcover&source=web&ots=upjyQA2XIn&sig=gBtrUy-6kRF-HaMr8T2FXppi4KY&sa=X&oi=book_result&resnum=2&ct=result] | |||

* A Catechism of the Steam Engine:[http://www.gutenberg.org/etext/10998] | |||

== Steam Engine Primers/Groups == | |||

'''Primers''' | |||

*http://www.pioneer.net/~carlich/RSE/ | * http://www.pioneer.net/~carlich/RSE/RSEprimer.html | ||

*http://www. | * http://www.the-nerds.org/Steam-101.html | ||

* Promising forum with large library of working steam engine plans: http://www.paddleducks.co.uk/ | |||

* | |||

'''Groups''' | |||

* | * [[Steam Automobile Club of America]] | ||

* | * [[The Only Production Steam Engine in the World]] | ||

* [[Tinytech]] | |||

* | |||

==See Also== | |||

{{Steam Engine}} | |||

Latest revision as of 17:31, 2 July 2013

Main > Energy > Steam Engine

see  Steam Engine

Steam Engine

Description

We are proposing an open-source steam engine project, to deliver a highly-efficient modern steam engine with the following features:

- Scalable power from 5 to 100 horsepower

- Modular design for easy building, maintenance, and repair

- Simple uniflow design - steam flows in a single direction from input valves to exhaust port(s)

- Modular crankshaft design to allow additional units to be added

Project goals include:

- Minimize expensive off-the-shelf components

- Minimize fabrication costs

- Easy to assemble and disassemble

- Easy to troubleshoot and repair

Reading About Steam Engines

Steam power is not taught in general. To master this topic, you should consider having a look at the information in Steam Engine Research/Books Tom Kimmel, of Kimmel Steam Power has some good material [1] as does Mike Brown in a reading list [2]. Description of this system by author and excellent background info on home power steam [3]. Skip Goebel has thoughts on an electronically controlled steam engine taken from [4].

Additional Information

- Category: Steam Engine

- Steam Engine/Index - steam engine pages organized by topic.

- Blog post and interview with Harry Schoell

- Related Forum - discussion forum.

- Steam Engine/Correspondence - reviews, messages, letters,etc.

- Steam Engine/Terminology - terms, jargon, abbreviations, etc.

- Steam Engine/Things To Do

- Steam Engine/Others - Links to commercially available steam engines, plans, other projects, etc.

Project Team

OSE:

- Marcin Jakubowski, Visionary

- Mark Norton, Project Manager

- Andrew Buck, Simulations, CAD

- Josh Jordan, Electronics and Sensors

Design Reviewers:

- Tom Kimmel, SACA

- Ken Helmick, SACA

- Harry Schoell, Cyclone Tech. ??

Additional Input:

- Ron Whaley, PKI Alumnus (White Cliffs Solar Project)

Joining the Steam Engine Team

OSE policies on GVCS projects specify that only active, contributing people are considered part of the project team. While we are always looking for people to help out, we need people who are committed to making real contributions. We do not need people who want to talk about building steam engines, we need people who want to design and actually build them. If you are such a person, please fill out the Team Culturing Survey and get yourself set up with accounts on the forum and wiki. All Steam Engine documentation is publicly posted on the OSE wiki.

After joining OSE, have a look at Steam Engine/Things To Do and the Steam Engine Pivotal Project [5]. Pivotal is a project management tool that allows us to track tasks that need to be done. Figure out what you are interested and what matches your skills and experiences. Then get in touch with the Steam Engine Project Manager (Mark Norton - markjnorton (at) earthlink (dot) net).

You will be given one or two tasks to complete before being invited as a full project participant. To some degree, this is a test of your commitment. More than that, it is a way of building trust in your ability to make a meaningful contribution. OSE GVCS Project teams are deliberately lean and agile. The pace can be fast at times and we need you to adapt to the current rate of development.

Design Rationale

Although it is a matter of some debate, there are many who feel that our global civilization has past the (so called) point of peak oil. Peak oil [6] refers to the point in time when easy sources of petroleum have been exhausted. Past that point, demand continues to rise (largely pegged to global population growth) but production rolls off. If we accept that we have past the point of peak oil, then how will we maintain civilization's need for energy? While part of the answer lies in reducing consumption, a bigger part lies in alternative sources of energy. The Open Source Ecology project is exploring a number of alternative energy sources. Given reliable energy sources, the Open Source Steam engine can be used to convert steam energy into motion (and thence into electricity, etc).

Steam engines have a number of benefits over other kinds of motive power:

- Relatively uncomplicated, few moving parts (compared to other engines)

- Driven by steam, produced in a variety of ways (boiler, solar concentrator, geothermal, etc.)

- Can be made modular: steam source, controller, cylinder, crankshaft

- Scalable power: connect more steam engine units onto a common crankshaft

- Easy to build: most parts can be fabricated from stock materials

Additional reasons to design and build an open source steam engine include:

- Relevant as an appropriate technology choice in both poor and rich countries when coupled to flash steam generators

- Basis for another kind of Power Cube

- May be coupled directly to linear hydraulic pump (feasibility study required)

Design

Overall design of the Open Source Steam Engine breaks down like this:

- Existing and Historic Designs

- OSE Engine Designs

- Steam Engine Design/2009 - an older design attempt

- Steam Engine Design - current design description

- Steam Engine Design/Solenoid - a future design

- Steam Engine Design/Valves - notes on different kinds of valves

- Steam Generator Designs

Summary of Proposed Design

The current OSE Modern Steam Engine is based on design developed for the White Cliffs solar power station in NSW, Australia (see Steam Engine Design/White Cliffs). While the White Cliffs engine used a converted diesel engine, the essential concept is the same: a uniflow steam engine using a bump valve control mechanism. Our engine is greatly simplified from the White Cliffs design. Initially, it will be a single cylinder (scalable by adding more to a common crankshaft) driven by steam from a boiler or solar concentrator (such as Solar Fire). Two bump valves are activated by valve pins mounted on the face of the piston head. Just before top dead center of the cycle, the bump the steam valves open, letting new steam into the cylinder. A flywheel carries the piston past top dead center and at the cut-off point, the steam valves close. Expanding pressure causes the piston to move down the cylinder until it nears bottom dead center, at which point the piston uncovers four exhaust vents allows steam (any any condensed water) to escape the engine. An exhaust plenum is provided to capture spent steam so that it might be used for other purposes (like heating).

Product Ecology

The steam engine gets inputs from:

- Solar Concentrator, Solar Fire

- Steam Generator

- Gassifier

and provides power to:

- Power Cube - Steam Engine version

- Tractor

- Open Source Car

- Truck

- Electric Generator

- Open Source Welder

- Aquaponics

- Greenhouse

Specifications

Inch to millimeter conversion chart [7].

Specifications including dimensions are provided in Steam Engine Specifications and complete building instructions are given in Steam Engine Build Instructions. Sourcing of parts is specified in Steam Engine Bill of Materials.

Costs

(Cost estimates go here)

Additional Links

- Biomass CHP with steam engine - [8]

- 60% vapor cycle efficiency in steam engine power plant? - [[9]]

- $300/hp steam engines in production, Peru - [10]

Steam Engine History

- Brief History of the Steam Engine

- The Steam Engine

- A History of the Growth of the Steam Engine: [11]

- A Catechism of the Steam Engine:[12]

Steam Engine Primers/Groups

Primers

- http://www.pioneer.net/~carlich/RSE/RSEprimer.html

- http://www.the-nerds.org/Steam-101.html

- Promising forum with large library of working steam engine plans: http://www.paddleducks.co.uk/

Groups