Helical Pier Fabrication: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| (3 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

|titlestyle = | |titlestyle = | ||

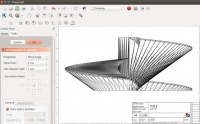

|image = [[File: | |image = [[File:helicalpier.jpg|200px|alt=Example alt text]] | ||

|imagestyle = | |imagestyle = | ||

|caption = Short description | |caption = Short description | ||

| Line 20: | Line 20: | ||

|header2 = | |header2 = | ||

|label2 = Product Ecology | |label2 = Product Ecology | ||

|data2 = | |data2 = Uses [[CNC Torch Table]] to cut the helix. Uses [[Welder]] to attach helix to shaft. Cuts shaft with [[CNC Multimachine]]. Uses [[3D Printing]] for wire arc additive manufacturing of joints. Uses [[Hot Dip Galvanizing]] for final coat (not included in the [[GVCS]]). Uses [[Universal Rotor]]-based helical pile driver with [[LifeTrac]] open source tractor, with [[Power Cube]] hydraulic takeoff. | ||

|header3 = | |header3 = | ||

|label3 = License | |label3 = License | ||

| Line 26: | Line 26: | ||

|header4 = | |header4 = | ||

|label4 = Module 1 | |label4 = Module 1 | ||

|data4 = | |data4 = Helix is CNC cut with 5 axis CNC torch table to get a leading edge. | ||

|header5 = | |header5 = | ||

|label5 = Module 2 | |label5 = Module 2 | ||

|data5 = | |data5 = Shaft is standard 2" pipe, 0.19" wall. | ||

|header6 = | |header6 = | ||

|label6 = Key Specification | |label6 = Key Specification | ||

|data6 = | |data6 = | ||

|header7 = | |header7 = | ||

|label7 = Construction | |label7 = Construction | ||

|data7 = | |data7 = Connector is [[WAAM]] 3D-Printed. | ||

|header8 = | |header8 = | ||

|label8 = Productivity | |label8 = Productivity | ||

|data8 = | |data8 = Allows for 1 day-builds of entire foundation systems, with 5 minute auger time per pile. | ||

|header9 = Completion Status | |header9 = Completion Status | ||

|label9 = | |label9 = | ||

| Line 44: | Line 44: | ||

|header10 = | |header10 = | ||

|label10 = | |label10 = | ||

|data10 = | |data10 = Design phase as of 9/16/20. See also [[Status of Completion]]. | ||

| Line 102: | Line 102: | ||

! scope=row | 9 | ! scope=row | 9 | ||

| [[Software]] || [[Open Source Helical Piers Software]] || 0 | | [[Software]] || [[Open Source Helical Piers Software]] || 0 | ||

|- | |||

! scope=row | 10 | |||

| [[Design Guide]] || [[Open Source Helical Piers Design Guide]] || 0 | |||

|- | |- | ||

Latest revision as of 16:50, 19 September 2020

| ||||||||||||||||||||||||

Development

Build Procedure

Steps:

- Get shaft

- Make sectional screw flight helix

- Weld on helix

- Make connector/driver attachment

- Weld on connector/driver attachment

- Hot dip galvanize the weldment

Making sectional screw flighting

Links

- Hot Dip Galvanizing - includes quotes