LifeTrac Construction Set: Difference between revisions

| Line 20: | Line 20: | ||

Image:Power_Cube_7s.png|Stable version of the Structural Power Cube from 2015 - [[Power Cube v15.6]]. See [[Power Cube Genealogy]] for all prior versions. | Image:Power_Cube_7s.png|Stable version of the Structural Power Cube from 2015 - [[Power Cube v15.6]]. See [[Power Cube Genealogy]] for all prior versions. | ||

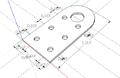

Image:Bondplate.png|[[Stock Bonding Plate]], 2013. | Image:Bondplate.png|[[Stock Bonding Plate]], 2013. | ||

Image:Ltframe6.jpg|Modular Wheel Unit, 2012. | Image:Ltframe6.jpg|[[Modular Wheel Unit]], 2012. | ||

Image:SPP-0709.png|Stock pivot plate, 1/2" steel. | Image:SPP-0709.png|[[Stock pivot plate]], 1/2" steel. | ||

Image:Lifetrac6cab.jpg|Frame Module, LifeTrac 6, 2013. This is an example of a typical frame that can be built from our stock tubing. See [[ | Image:Lifetrac6cab.jpg|Frame Module, LifeTrac 6, 2013. This is an example of a typical frame that can be built from our stock tubing. See [[LifeTrac 6]] for details | ||

File:Backhoe.jpg|Backhoe prototype 1. It was built as a front attachment for [[LifeTrac 1]], and side to side motion was obtained via articulation of the tractor. | File:Backhoe.jpg|Backhoe prototype 1. It was built as a front attachment for [[LifeTrac 1]], and side to side motion was obtained via articulation of the tractor. | ||

</gallery> | </gallery> | ||

Revision as of 03:27, 24 January 2016

Requirements - 2015

Modules

This page has been updated last on: Jan 23, 2016

Introduction: After 7 years of prototyping (see Prototypes Built and Cost), about 50 different primitive modules have been designed, built, and tested. These serve as the building blocks in OSE's Construction Set Approach. The goal of the following gallery is to provide an overview of the scope of what has been accomplished, with a focus on explaining the ecology of modules that are being created. These modules fit together and can be mashed up to form an unlimited number of machines. Ie, after years of builds, we are observing that an ecology of modules is emerging in a coherent way, and initial results indicate that a veritable Construction Set for all kinds of machines can be created. This brings to life the identity of OSE's work as a Life-Size Lego Set for production tools. We have shown both Intensive Scalability and Extensive Scalability, have stacked up to 3 Power Cubes for 75 hp, and have gone through more than 6 iterations on the Power Cube, CEB Press, and Tractor.

LifeTrac Primitives

We are listing all the modules here for porting to FreeCAD format.

LifeTrac Construction Set Primitive Modules. These modules are parts that go into a tractor, and can be used to build various other machines of a similar nature.

Stable version of the Structural Power Cube from 2015 - Power Cube v15.6. See Power Cube Genealogy for all prior versions.

Stock Bonding Plate, 2013.

Modular Wheel Unit, 2012.

Stock pivot plate, 1/2" steel.

Frame Module, LifeTrac 6, 2013. This is an example of a typical frame that can be built from our stock tubing. See LifeTrac 6 for details

Backhoe prototype 1. It was built as a front attachment for LifeTrac 1, and side to side motion was obtained via articulation of the tractor.

Other Machines

Other Construction Set Style Machines that were built:

Other Machines, Not Built

Other Construction Set Style Machines, not built:

See Pelletizer Log for files.

LifeTrac Construction Set Design Guidelines - 2013

- Mechanical: Use 4”x4” tubing, Stock Pivot Plates, and Stock Bonding Plates

- Custom plates are used whenever stock plates do not have the required geometry.

- Use Power Beyond Sleeve for power downstream

General Quality Control

- Minimize parts count

- Calculate overall cost and minimize parts count by smart design

- Minimize the amount of material used by simplifying design

- Minimize hose lengths

See 3 Month Prototyping Plan 2013 for prototyping plan of Q2, 2013.

Overview of Need

Affordable, user-centred equipment that can be manufactured wherever stock steel and parts can be obtained. The goal is to produce industrial machinery - such as tractors - which can be used to produce hundreds of thousands of horsepower hours per year at an operating cost of $500 per year, Fuel Included.*

Technology Concept

We are using square tubing and various plates as a route to creating a Universal Construction Set for heavy machinery. Together with interchangeable power units, wheel modules, and other modules - and by adding certain dedicated components - one can build just about any heavy machine. Conceptual examples are shown below.

We are transitioning the build of LifeTrac and related machines to fabrication with the CNC Torch Table to allow for 1-day builds of each machine. This utilizes primarily 1/2" steel and 4"x4" steel tubing for building out modular components. Allows for similarity in build out of tractor and variants, micro-tractor, bulldozer, truck, backhoe, power unit, hammer-mill, sawmill, iron-worker machine, micro-combine modules, backhoe with 360 degree rotation, pelletizer, car, trencher, universal rotor, universal seeder (with plow/disc/cultivator modules/rotary cutter (hay cutter), hay rake), well drilling rig, and CNC torch table/large Gantry Mill.

Rollout Sequence

The roll out sequencing for the Tractor Construction Set looks like this:

Module Based Design

For the above, the Module Based Design strategy looks like this:

Vehicle Frames

Frames Allow Various Attachments

Power Cube Construction Set

Steps

- Build XYZ structure Power Cube, Prototype VIII

- Add wheels and control.

- Add Quick Attach module

- Add equipment modules

Stiff Joints

Pivoting Joints

Pivoting Joints 2

Scalable, Open Source Car

Strategy:

- Utilize suspension module from Team Wikispeed Car

- Build upon specs of 0.19 coefficient of drag 260 mpg Car

Pivot Joint Scalability

Scalable Ironworker Machine

Hydraulic Quick Couplers

Resource Allocation

Machine Rollout and Budget rationale is such:

Economic Analysis

Strategic Partnerships

- iF Foundation - tractor pilot in Haiti

- College Catts Pressoir - tractor pilot in Haiti

- Guatemala Log - tractor pilot

- Berea College - tractor pilot for 500 acre farm

- Cornell University - agriculture equipment pilot; leader in agriculture on the East Coast, USA

- Olin College - engineering development; radical engineering school

- Global TIES - U.C. San Diego - on machine development

- Adabio - Universal Implement Mount, tractor drawn implements

Implementation Priorities

- Establish Communication Channels - IRC, email, stack overflow, Twitter handle, Facebook group, wiki team page, CiviCRM contact base, True Fans Network? Invite LifeTrac Construction Set moderator.

- Establish Technical Review Team

OSE intends to build out a 50 hp 1.6 Liter Air Cooled VW engine-based Power Cube, followed by either Joe's 150hp PowerCube with the most efficient Honda engine - but that engine is $8k with radiator - or a Modern Steam Engine powered Power Cube. We need up to 300 hp for larger power machines like bulldozer, or for 200kW of electrical power generation for producing local steel with a 200 kW Induction Furnace.

Tehnical Strategies

I have been thinking about 4x4 tubing as the industry standard for OSE, in 3/16-1/2" wall thickness. This allows us to do everything from microtractor to tractor to bulldozer frames, backhoes + truck bodies + CNC Torch Table frame + Power Cube frames. For the latter, the power cube itself become highly structural and you can use the Power Cube itself as part of the vehicle frame. To do this, I am considering welded nuts inside the frame member so one could impact wrench the corners quickly and easily, or we can do metal connectors.