D3D v20.04: Difference between revisions

(→3D CAD) |

|||

| (8 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=Summary= | |||

D3D printer with 12", insulated heatbed. This is the next to last iteration of build prior to upgrading to the single-piece 3D printed axis pieces. | |||

=Developent Template= | =Developent Template= | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 126: | Line 129: | ||

=3D CAD= | =3D CAD= | ||

[[File:d3d_v2004.png|100px]][[File:withsidehole.png|100px]][[File:fattened.png|100px]][[File:autop.png|100px]][[File:newbedholder.png|100px]][[File:newbedholder2.png|100px]][[File:newbedholder3.png|100px]][[File:panelholder.png|100px]][[File:endstopstopcombo.png|100px]][[File:extendedpanelholder.png|100px]][[File:bespacer.png|100px]][[File:transversebedholder.png|100px]][[File:transversebedholder2.png|100px]] | [[File:d3d_v2004.png|100px]][[File:withsidehole.png|100px]][[File:fattened.png|100px]][[File:autop.png|100px]][[File:newbedholder.png|100px]][[File:newbedholder2.png|100px]][[File:newbedholder3.png|100px]][[File:panelholder.png|100px]][[File:endstopstopcombo.png|100px]][[File:extendedpanelholder.png|100px]][[File:bespacer.png|100px]][[File:transversebedholder.png|100px]][[File:transversebedholder2.png|100px]][[File:counterweightconcept.png|100px]][[File:autoparallelredone.png|100px]][[File:idlermountnew.png|100px]] | ||

<gallery perrow=6> | <gallery perrow=6> | ||

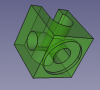

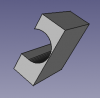

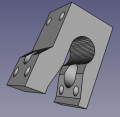

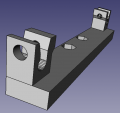

File:idlermountnew.png|'''New idler mount''' - FreeCAD -[[File:newidlermount.fcstd]] | |||

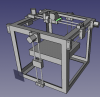

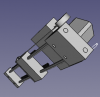

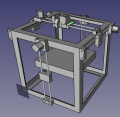

File:d3d_v2004.png|'''D3D v2004 Assembly''' - FreeCAD -[[File:d3d_v2004.fcstd]] | File:d3d_v2004.png|'''D3D v2004 Assembly''' - FreeCAD -[[File:d3d_v2004.fcstd]] | ||

File: | |||

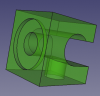

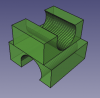

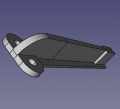

File:autoparallelredone.png|'''Auto parallel piece.''' Can be used on Y for auto parallel, Z for equal bottoming. File: [[File:autoparallel.fcstd]] [[File:autoparallel.stl]] | |||

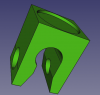

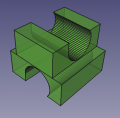

File:newbedholder3.png|'''New bed holder.''' File: [[File:newbedholder.fcstd]] [[File:newbedholder.stl]] | File:newbedholder3.png|'''New bed holder.''' File: [[File:newbedholder.fcstd]] [[File:newbedholder.stl]] | ||

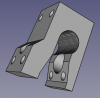

File:extendedpanelholder.png|'''Panel holder.''' File: [[File:panelholder.fcstd]] [[File:panelholder.stl]] | File:extendedpanelholder.png|'''Panel holder.''' File: [[File:panelholder.fcstd]] [[File:panelholder.stl]] | ||

| Line 138: | Line 146: | ||

File:transversebedholder2.png|'''Transverse bed holder.''' File: [[File:transversebedholder.fcstd]] [[File:transversebedholder.stl]] | File:transversebedholder2.png|'''Transverse bed holder.''' File: [[File:transversebedholder.fcstd]] [[File:transversebedholder.stl]] | ||

File:counterweightconcept.png|'''Counterweight.''' File: [[File:counterweightconcept.fcstd]] [[File:counterweightconcept.stl]] | |||

</gallery> | </gallery> | ||

| Line 143: | Line 154: | ||

Using [[3D Printer Workbench 2020]]: | Using [[3D Printer Workbench 2020]]: | ||

# | #[2] 22” - X | ||

# | #[4] 21” - Y | ||

#Z, bed, spool holder | #[9] 17” Z, bed, spool holder | ||

=Heater Element Wrapping Procedure= | =Heater Element Wrapping Procedure= | ||

Latest revision as of 01:52, 17 September 2020

Summary

D3D printer with 12", insulated heatbed. This is the next to last iteration of build prior to upgrading to the single-piece 3D printed axis pieces.

Developent Template

Working Doc

3D CAD

New idler mount - FreeCAD -File:Newidlermount.fcstd

D3D v2004 Assembly - FreeCAD -File:D3d v2004.fcstd

Auto parallel piece. Can be used on Y for auto parallel, Z for equal bottoming. File: File:Autoparallel.fcstd File:Autoparallel.stl

New bed holder. File: File:Newbedholder.fcstd File:Newbedholder.stl

Panel holder. File: File:Panelholder.fcstd File:Panelholder.stl

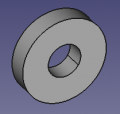

Bed spacer. File: File:Bedspacer.fcstd File:Bedspacer.stl

Transverse bed holder. File: File:Transversebedholder.fcstd File:Transversebedholder.stl

Counterweight. File: File:Counterweightconcept.fcstd File:Counterweightconcept.stl

Cut List

Using 3D Printer Workbench 2020:

- [2] 22” - X

- [4] 21” - Y

- [9] 17” Z, bed, spool holder

Heater Element Wrapping Procedure

- Cut 14' of ga 24 nichrome

- Cut 5' of tight 2 mm fiberglass sleeve

- start the wrap of nichrome on one end of sleeve

- Attach other end of sleeve to a free-spinning rotor

- Once enough to go inside a cordless drill chuck - grab the nichrome wrap and turn on the drill in reverse to start wrapping. Tension the sleeve against the rotor

- Wrap away! A person should be able to wrap 4 feet long just by holding a cordless drill

Questions

-Back to working some on PVC 12" - was there enough torque to lift that bed with 2 Z steppers? I don't seem to have enough with properly tightened axis.