D3D Universal: Difference between revisions

No edit summary |

|||

| Line 12: | Line 12: | ||

{{Hint|Stable version uses MK7 drive gear (1.75 mm version) and Volcono nozzle (0.6mm tested) and 3 mm heat break and a half nut (6 mm) under the heat sink but above the thin break section. Filament is not constrained for 4 mm prior to heat break, but works great with PLA. Doesn't work with TPU.}}. | {{Hint|Stable version uses MK7 drive gear (1.75 mm version) and Volcono nozzle (0.6mm tested) and 3 mm heat break and a half nut (6 mm) under the heat sink but above the thin break section. Filament is not constrained for 4 mm prior to heat break, but works great with PLA. Doesn't work with TPU.}}. | ||

[[File:earlymodel.png|100px]][[File:extruderspring.png|100px]][[File:volcanoheaterblock.png|100px]] [[File:Cc_heat_sink_block_jig_03NOV2019.png|100px]][[File:dynamicblower.jpg|100px]][[File:withsensor.png|100px]][[File:steppermotor.png|100px]][[File:steppermotor2.png|100px]][[File:extruderwithmotorandsensor.png|100px]][[File:drivegear.png|100px]][[File:Cc_bearing_hobbolt_04NOV2019.png|100px]][[File:ChrisStartupCampFinal.png|100px]][[File:RecessedAndOversizedHoles.png|100px]] | [[File:earlymodel.png|100px]][[File:extruderspring.png|100px]][[File:volcanoheaterblock.png|100px]] [[File:Cc_heat_sink_block_jig_03NOV2019.png|100px]][[File:dynamicblower.jpg|100px]][[File:withsensor.png|100px]][[File:steppermotor.png|100px]][[File:steppermotor2.png|100px]][[File:extruderwithmotorandsensor.png|100px]][[File:drivegear.png|100px]][[File:Cc_bearing_hobbolt_04NOV2019.png|100px]][[File:ChrisStartupCampFinal.png|100px]][[File:RecessedAndOversizedHoles.png|100px]][[File:3heatbreak.png|100px]] | ||

<gallery perrow=6> | <gallery perrow=6> | ||

| Line 50: | Line 50: | ||

File:drivegear.png| '''Drive Gear'''[[File:drivegear.fcstd]] | File:drivegear.png| '''Drive Gear'''[[File:drivegear.fcstd]] | ||

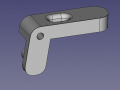

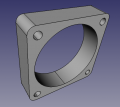

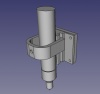

File:3heatbreak.png| '''3 mm heat break.'''[[File:3heatbreak.fcstd]] | |||

</gallery> | </gallery> | ||

Revision as of 06:10, 25 November 2019

3D Printer

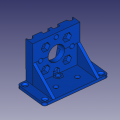

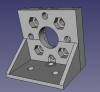

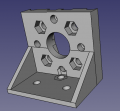

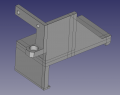

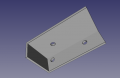

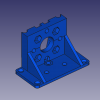

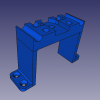

Mount of Z motor to base plate. File:D3DS motor bracket x axis.fcstd

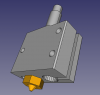

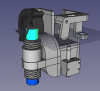

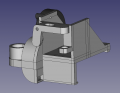

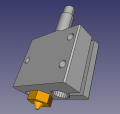

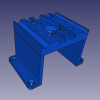

CAD - 3D Printer Extruder

![]() Hint: Note the small extruder gear shown is MK8- we are using an MK7. Note: Supervolacon nozzle has heat transfer issues, so we are using a 3 mm E3D v6 heat break with success (6mm threads on both sides - note that E3D v6 has 6 mm on the nozzle side, 7 mm on the cold side. Can also test Titan Aero v6 1.75 mm - which appears to have 6 mm thread on both sides. 3mm titan aero is definitely 6 mm thread on each side: see E3D_Titan_Aero_Extruder#CAD

Hint: Note the small extruder gear shown is MK8- we are using an MK7. Note: Supervolacon nozzle has heat transfer issues, so we are using a 3 mm E3D v6 heat break with success (6mm threads on both sides - note that E3D v6 has 6 mm on the nozzle side, 7 mm on the cold side. Can also test Titan Aero v6 1.75 mm - which appears to have 6 mm thread on both sides. 3mm titan aero is definitely 6 mm thread on each side: see E3D_Titan_Aero_Extruder#CAD

![]() Hint: Stable version uses MK7 drive gear (1.75 mm version) and Volcono nozzle (0.6mm tested) and 3 mm heat break and a half nut (6 mm) under the heat sink but above the thin break section. Filament is not constrained for 4 mm prior to heat break, but works great with PLA. Doesn't work with TPU.

Hint: Stable version uses MK7 drive gear (1.75 mm version) and Volcono nozzle (0.6mm tested) and 3 mm heat break and a half nut (6 mm) under the heat sink but above the thin break section. Filament is not constrained for 4 mm prior to heat break, but works great with PLA. Doesn't work with TPU.

.

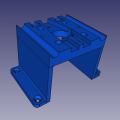

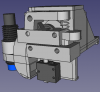

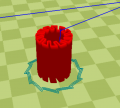

Simple Extruder WIP. Github - [1]. Gitlab - [https://gitlab.com/marcin_ose/d3d-universal.

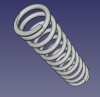

Extruder Spring for Simple Extruder. Buy + spec - [2]. FreeCAD file - File:Extruderspring.fcstd

Extruder assembly - https://gitlab.com/marcin_ose/d3d-universal/blob/master/SimpleExtruder.FCStd

Extruder motor bracket - https://gitlab.com/marcin_ose/d3d-universal/blob/master/ExtruderMotorBracket.FCStd

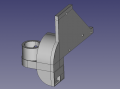

Extruder Active Cooling and Sensor Mount File:ExtruderActiveCoolingAndSensor.FCStd

Spring tensioner -File:SpringTensioner.FCStd

Jig to cut the heat sink -File:HeaterSinkJig.FCStd

heat sink -File:HeatSink.FCStd

Spiral linear bearing - parametric, but parameters set up for D3D -File:SpiralLinearBearing.zip

Volcano heater block. File:Volcanoheaterblock.fcstd.

File:5015blower.fcstd 5015 Blower - positionally correct for D3D Universal.

8 mm sensor. Download - File:8mmsensor.fcstd

608 skateboard 8x22x7 mm Bearing. Download - File:608Bearing.FCStd

40x10mm fan File:40x10fan.fcstd

Stepper MotorFile:Steppermotor.fcstd

Stepper Motor from FaceplateFile:Nema17face.fcstd

Super Volcano NozzleFile:SuperVolcanoNozzle.fcstd

Drive GearFile:Drivegear.fcstd

3 mm heat break.File:3heatbreak.fcstd

BOM

- Spring - [7]

Working Doc

Includes Review and Data Collection

| Description | Link to Work Product | % | |

|---|---|---|---|

| DESIGN | |||

| 1 | Requirements + Value Proposition | [[{{{0}}} Requirements + Value Proposition]] | {{{1}}} |

| 2 | Industry_Standards | [[{{{0}}} Industry Standards]] | 50 |

| 3 | Conceptual Design | [[{{{0}}} Conceptual Design]] | {{{3}}} |

| 4 | Module Breakdown | [[{{{0}}} Module Breakdown]] | {{{4}}} |

| 5 | 3D CAD | [[{{{0}}} 3D CAD]] | {{{5}}} |

| 6 | Calculations | [[{{{0}}} Calculations]] | {{{6}}} |

| 7 | Electronics Design | [[{{{0}}} Electronics Design]] | {{{7}}} |

| 8 | Wiring and Plumbing | [[{{{0}}} Wiring and Plumbing]] | {{{8}}} |

| 9 | Software | [[{{{0}}} Software]] | {{{9}}} |

| BILL OF MATERIALS | |||

| 10 | BOM | [[{{{0}}} BOM]] | 50 |

| 11 | vBOM | [[{{{0}}} vBOM]] | {{{11}}} |

| 12 | CAM Files | [[{{{0}}} CAM Files]] | {{{12}}} |

| 13 | Cut List | [[{{{0}}} Cut List]] | {{{13}}} |

| BUILD | |||

| 14 | Build Instructions | [[{{{0}}} Build Instructions]] | 20 |

| 15 | Fabrication Drawings | [[{{{0}}} Fabrication Drawings]] | {{{15}}} |

| 16 | Exploded Part Diagram | [[{{{0}}} Exploded Part Diagram]] | {{{16}}} |

| 17 | Production Engineering | [[{{{0}}} Production Engineering]] | {{{17}}} |

| DATA COLLECTION | |||

| 18 | Build Pictures and Video | [[{{{0}}} Build Pictures and Video]] | {{{18}}} |

| 19 | Data Collection | [[{{{0}}} Data Collection]] | {{{19}}} |

| 20 | Future Work | [[{{{0}}} Future Work]] | {{{20}}} |

Build

D3D Universal Axis

Platform on stilts so extruder reaches bed:

Nozzle does not reach bed:

Extruder

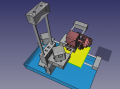

3-in-1 Machine

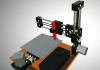

D3D Universal with 3D printer motor functioning as a CNC mill. - FreeCAD -[3] or Michel's repo.

D3D Simple Working Copy by Marcin - FreeCAD -File:D3Dsimple.fcstd

D3D Universal with plotter attachment. - See D3D Universal Plotter by Ferdi Meier. Gitlab - [4]

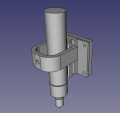

Plotter Pen Attachment. - File:Plotterpen.fcstd. From Ferdi Log.

Simple extruder for 1.75 mm filament. - By London International Academy team. From Simple Extruder.

Simple spindle - By John Stager team. See Simple Spindle.

Arduino Uno for motor power supply. See Emmanuel Log.

D3DS motor piece with bracket for x and z-axis

FreeCAD file -File:D3DS motor bracket.fcstd

STL file -File:D3DS motor bracket.stlD3DS elevated idler side piece for Y-axis

FreeCAD file -File:D3DS idler high screwdown.fcstd

STL file -File:D3DS idler high screwdown.stlD3DS elevated motor side piece for Y-axis

FreeCAD file -File:D3DS motor side high screwdown.fcstd

STL file -File:D3DS motor side high screwdown.stl

Design Concepts

Plotter

embedded my website on wiki https://feadi.github.io/OSE/.

Played with gtlf-viewer

Wiring

Code

- Marling - File:Marlin Universal.zip

Links

- D3D Simple - build from 2019

![Simple Extruder WIP. Github - [1]. Gitlab - [https://gitlab.com/marcin_ose/d3d-universal.](/images/thumb/5/59/CC_simple_extruder_dev_03NOV2019.png/120px-CC_simple_extruder_dev_03NOV2019.png)

![Extruder Spring for Simple Extruder. Buy + spec - [2]. FreeCAD file - File:Extruderspring.fcstd](/images/thumb/7/79/Extruderspring.png/120px-Extruderspring.png)

![D3D Universal with 3D printer motor functioning as a CNC mill. - FreeCAD -[3] or Michel's repo.](/images/thumb/6/6e/D3duniversalmill.png/120px-D3duniversalmill.png)

![D3D Universal with plotter attachment. - See D3D Universal Plotter by Ferdi Meier. Gitlab - [4]](/images/thumb/8/88/D3Duniversalplotter1.jpg/120px-D3Duniversalplotter1.jpg)

![Electric Motor. Michel Repo - [5]. Assembly in FreeCAD, Marcin's Repo - [6]](/images/thumb/5/58/Electricmotor.png/120px-Electricmotor.png)