D3D

Development discussion takes place at the Development Group. Also, see D3D Log and D3D Performance Log and D3D Serial Numbers for the machines that were built. The Performance Log should track issues and be used in quality control.

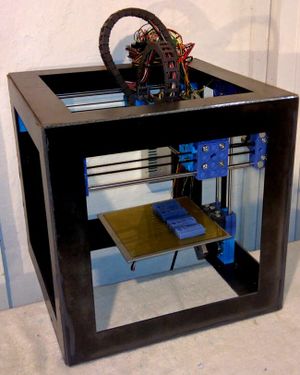

![]() Hint: The D3D 3D printer is a modular and scalable 3D printer. Different toolheads can be used via a magnetic tool mount.

Hint: The D3D 3D printer is a modular and scalable 3D printer. Different toolheads can be used via a magnetic tool mount.

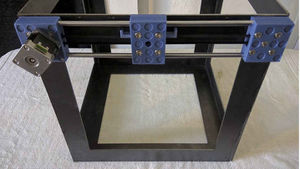

See Build Instructions. See D3D Genealogy. ![]()

![]() Hint: To join the working team, see how to apply as an OSE Developer. See the Development Group on the OSE Network.

Hint: To join the working team, see how to apply as an OSE Developer. See the Development Group on the OSE Network.

For information on how to build the most recent replications and on recent development effort, see: D3D Landing Page

Basics

- A 3D Printer that uses the Universal Axis

- It has a low part count compared to other 3D Printers

- It is also easier to build due to the identical axis' and the overall build modularity

- It can be converted to many other CNC Machienes due to the swappable tool head (See the Open Source Digital Fabrication Construction Set )

Active Team Members

See D3D Meeting Log for current team members.

Part Library

Versions

For a complete list of D3D version history, see 3D Printer Genealogy

v18.06

This printer was built on 2018-06-02 at a workshop. For more info on that build, see D3D_Workshop_2018-06-02.

Other Versions

CAD

Overall assembly. File:D3D CAD Assembly.fcstd. See D3D Part Library for spreadsheet of modules and list of 3d printed parts. Note also that the spreadsheet contains ~23kb axis files - which are simplified greatly while retaining onlly the critical design components.

Frame Build

Axis

See Universal Axis

Integration

Intro

D3D is a Distributive Enterprise 3D printer. If the plans are truly open source including the Extreme Manufacturing business model for replication - and if Viral Replicability Criteria are reached - we predict that this will become the most replicated 3D printer in the world within one year of the above criteria being reached. Join the effort as an OSE Developer to make this happen.

Modules

see D3D Modules

Critical Path

Meeting Log

- D3D Meeting Log - D3D Meeting Log

BOM

See BOM Template for more info on how to build a proper BOM.

See D3D BOM

Development Template

Product Ecology

- Grinder

- Extruder

- Filament maker

Enterprise

- 3D Printed Cordless Drill

- Filament Production

- XM Workshops

Distributive Enterprise

Working Doc

Replications

- D3D Hamburg

- Chile D3D

- D3D Australia

- D3D Joe Haas

- D3D_Ohio_v18.02 WIP 12" bed PVC

- D3D_@_Fontys_Sittard