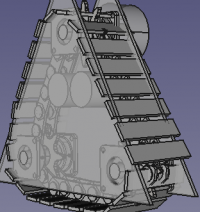

Short description |

| Specifications |

|---|

| Product Ecology |

To be built with the D3D CNC Torch Table |

|---|

| License |

OSHWA and OSI compliant. CC-BY-SA-4.0 International, GPLv3, DIN SPEC 3105. |

|---|

| Motor |

Can use a small hydraulic motor with 3-4 geardown. |

|---|

| Track Tensioners |

2 Identical track tensioners tensions motor and track independently |

|---|

| Key Specification |

Scalable to multiple motors, different geardown ratios, and capable of being stacked in dually configuration. Maximum design drive is 13,000 lb potential drawbar pull per track unit. |

|---|

| Key Specification |

Drive system applicable to traction machines with each track unit ranging from 1400 lb at 4 mph and 10 gpm (20 hp) at 3x geardown, to 1400 lb and 8 mph at 20 gpm (40 hp) and single motor, to 2800 lb at 4 mph and 20 gpm with dual drive motor (40 hp), to 5600 lb power operation with dual motors at 40 gpm at 4 mph (80 hp) and 6x geardown. |

|---|

| Construction |

CNC cut steel, stock steel, and off-the-shelf bearings + motors. 300-600 lb each Universal Track Unit. |

|---|

| Productivity |

Practical range from 10-80 hp per drive unit using the same parts, for applications from small walk-behind tractors to small bulldozers. |

|---|

| Cost |

$300 for Slow Solar version - $600 for standard power |

|---|

| Completion Status |

|---|

|

Describe whether built, prototyped, etc. Link to relevant Genealogy and Status of Completion. |

| Do you want more of this? Get Involved |

| v · d · e |