Global Village Construction Set: Difference between revisions

No edit summary |

No edit summary |

||

| Line 13: | Line 13: | ||

The ideas that guide the GVCS are: | The ideas that guide the GVCS are: | ||

'''Open Source''' - we freely publish our 3d designs, schematics, instructional videos, budgets, and product manuals on our open source wiki and we harness open collaboration with technical contributors. | '''Open Source''' - we freely publish our 3d designs, schematics, instructional videos, budgets, and product manuals on our open source wiki and we harness open collaboration with technical contributors. | ||

Revision as of 17:20, 6 May 2011

![]() It has been suggested that the text on [[::GVCS tools|GVCS tools]] be merged into (added to) this page or section. (Discuss)

It has been suggested that the text on [[::GVCS tools|GVCS tools]] be merged into (added to) this page or section. (Discuss)

![]() It has been suggested that the text on [[::Template:GVCS List|Template:GVCS List]] be merged into (added to) this page or section. (Discuss)

It has been suggested that the text on [[::Template:GVCS List|Template:GVCS List]] be merged into (added to) this page or section. (Discuss)

uid="marcin_ose" title="Global Village Construction Set" description="The GVCS is a set of 50 tools / technologies for building post-scarcity, resilient communities." category="text" language="en_GB" button="compact"/>

The GVCS is a set of 50 tools / technologies for building post-scarcity, resilient communities.

The ideas that guide the GVCS are:

Open Source - we freely publish our 3d designs, schematics, instructional videos, budgets, and product manuals on our open source wiki and we harness open collaboration with technical contributors.

Low-Cost - The cost of making or buying our machines are, on average, 8x cheaper than buying from an Industrial Manufacturer, including an average labor cost of $15 hour for a GVCS fabricator.

Modular - Motors, parts, assemblies, and power units can interchange, where units can be grouped together to diversify the functionality that is achievable from a small set of units.

User-Serviceable - Design-for-disassembly allows the user to take apart, maintain, and fix tools readily without the need to rely on expensive repairmen.

DIY - (do-it-yourself) The user gains control of designing, producing, and modifying the GVCS tool set.

Closed Loop Manufacturing - Metal is an essential component of advanced civilization, and our platform allows for recycling metal into virgin feedstock for producing further GVCS technologies - thereby allowing for cradle-to-cradle manufacturing cycles

High Performance - Performance standards must match or exceed those of industrial counterparts for the GVCS to be viable.

Flexible Fabrication - It has been demonstrated that the flexible use of generalized machinery in appropriate-scale production is a viable alternative to centralized production.

Distributive Economics - We encourage the replication of enterprises that derive from the GVCS platform as a route to truly free enterprise - along the ideals of Jeffersonian democracy.

Industrial Efficiency - In order to provide a viable choice for a resilient lifestyle, the GVCS platform matches or exceeds productivity standards of industrial counterparts.

The tools

| CEB Press | A high-performance Compresssed Earth Block press. Compresssed Earth Block building is the highest quality natural building method. The page CEB intro contains introductory information on compressed earth blocks | http://openfarmtech.org/temp-gvcs-icons/compressed-earth-brick-press.png | COMPLETE AND TESTED! |

|---|---|---|---|

| Tractor | A versatile, 4-wheel drive, hydraulically-driven, skid-steering tractor with 18 to 200 horsepower capacity for agriculture, construction and other utility duties. | http://openfarmtech.org/temp-gvcs-icons/lifetrac.png | PROTOTYPE COMPLETE! |

| Microtractor | a small, 18 hp version of the full-sized tractor for powering a wide range of implements in agricultural and utility duties | http://openfarmtech.org/temp-gvcs-icons/microtrac.png | PROTOTYPE COMPLETE! |

| Bulldozer | A high-traction, heavy earth-moving machine indispensible for building ponds, berms, and other permacultural earthforms, as well as for other tasks such as building roads or clearing land | http://openfarmtech.org/temp-gvcs-icons/bulldozer.png | STATUS |

| Power Cube | A multipurpose, self-contained, hydraulic power power unit that consisting of an engine coupled to a hydraulic pump | http://openfarmtech.org/temp-gvcs-icons/powercube.png | PROTOTYPE COMPLETE! |

| CNC Precision Multimachine | A multipurpose, precision CNC machining and metal cutting device for milling, lathing, drilling to make precision parts; includes surface grinding and cold-cut metal sawing | http://openfarmtech.org/temp-gvcs-icons/multimachine.png | STATUS |

| Ironworker Machine | A device that can instantly cut steel and punch holes in metal one inch thick | http://openfarmtech.org/temp-gvcs-icons/ironworker.png | STATUS |

| CNC Torch/Router Table | A computer-controlled cutting table for metal where a moving torch head is used to produce precision metal parts in a fraction of the time that it takes to do so manually | http://openfarmtech.org/temp-gvcs-icons/torch-table.png | PROTOTYPE COMPLETE!

|

| 3D Printer | An additive manufacturing technology where a three dimensional object is printed by laying down successive layers of material, just like a printer except in 3D | http://openfarmtech.org/temp-gvcs-icons/3d-printer.png | COMPLETE AND TESTED!

|

| 3D Scanner | A device that can generate a 3D digital scan from a real-life object, where the file can be used to reproduce the object in 3D with a device such as the 3D printer or CNC Precision Multimachine | http://openfarmtech.org/temp-gvcs-icons/3d-scanner.png | STATUS |

| CNC Circuit Mill | A computer-controlled device that can produce electrical circuits by milling and drilling on copper-clad circuit boards | http://openfarmtech.org/temp-gvcs-icons/circuit-mill.png | STATUS |

| Industrial Robot | A robotic arm which can perform certain human tasks - such as welding or milling – for performing tasks that are not better done by humans | http://openfarmtech.org/temp-gvcs-icons/robotic-arm.png | STATUS

|

| Laser Cutter | An industrial machine that can make precision, finish cuts in a wide array of substrates, such as metal, wood, or plastic | http://openfarmtech.org/temp-gvcs-icons/laser-cutter.png | STATUS |

| Open Source Welder | A device used to make strong, permanent bonds in metal by melting and fusing the metal | http://openfarmtech.org/temp-gvcs-icons/mig-welder.png | STATUS |

| Plasma Cutter | A device to cut metal using a plasma torch | http://openfarmtech.org/temp-gvcs-icons/plasma-cutter.png | STATUS |

| Induction Furnace | An electrical furnace in which the heat is applied by induction heating of metal, providing clean, versatile, compact, energy-efficient, and well-controlled melting compared to flame furnaces | http://openfarmtech.org/temp-gvcs-icons/induction-furnace.png | STATUS |

| Metal Rolling | A metal forming process in which metal stock is passed through a pair of rolls to produce a desired shape, such as flat bar, angle, or u-channel | http://openfarmtech.org/temp-gvcs-icons/metal-rolling-machine.png | STATUS |

| Rod and Wire Mill | A subset of metal rolling, used to make shafts, rebar, thin rods, and down to wire. | http://openfarmtech.org/temp-gvcs-icons/wire-n-rod-mill.png | STATUS |

| Press Forge | A device for shaping metal by the application of a shaping die and a continuous pressure or force. | http://openfarmtech.org/temp-gvcs-icons/forge.png | STATUS |

| Modern Steam Engine | A modern engine where an external heat source is used to turn water into steam, and the steam in turn moves reciprocating pistons to provide shaft power | http://openfarmtech.org/temp-gvcs-icons/steam-engine.png | STATUS |

| Gasifier burner | A clean and efficient burner that gasifies the material that is being burned prior to combustion | http://openfarmtech.org/temp-gvcs-icons/gasifier-burner.png | STATUS |

| Steam Generator | A device that generates steam from water that is passed through externally-heated coils | http://openfarmtech.org/temp-gvcs-icons/steam-generator.png | STATUS |

| Linear Solar Concentrator | An infinitely-scalable, linear device which concentrates solar radiation onto a linear target for generating heat or steam to produce electricity | http://openfarmtech.org/temp-gvcs-icons/solar-concentrator.png | STATUS |

| Fifty kilowatt Wind Turbine | A device that produces electrical power from wind energy, scalable in units of 50kW | http://openfarmtech.org/temp-gvcs-icons/wind-turbine.png | STATUS |

| Aluminum Extractor from Clay | Adevice that produces aluminum from clay by dissolving the aluminum from aluminosilicate (clay), and then electrolyzing the resulting compound to form pure aluminum | http://openfarmtech.org/temp-gvcs-icons/alluminum-extractor.png | |

| Pelletizer | A device that compresses shredded pieces of biomass or other substances to compact, flowable pellets | http://openfarmtech.org/temp-gvcs-icons/pelletizer.png | |

| Universal Seeder | A tractor-pulled seeder than can plant any seed, from small seeds like clover to large seeds such as potatoes | http://openfarmtech.org/temp-gvcs-icons/universal-seeder.png | |

| Rototiller and Soil Pulverizer | A tractor implement that tills soil with blades via rotary action | http://openfarmtech.org/temp-gvcs-icons/pulverizer-tiller.png | |

| Spader | A set of mechanical shovels that prepare soil for planting without causing a hardpan typical of rototiller tilling | http://openfarmtech.org/temp-gvcs-icons/spader.png | |

| Microcombine | A small-scale harvester-thresher for mechanical harvesting of any grain crops, with a cutting swath of about 3 feet in width | http://openfarmtech.org/temp-gvcs-icons/microcombine.png | |

| Universal Rotor | A tractor-mounted rotor that can be fitted with a wide array of toolheads, such as string trimmer, posthole digger, tree planting auger, slurry mixer, and many others | http://openfarmtech.org/temp-gvcs-icons/universal-rotor.png | |

| Baler | A device that compresses hay and other light and dispersed materials into more compact bales | http://openfarmtech.org/temp-gvcs-icons/baler.png | |

| Hay Rake | A mechanical implement for a tractor that rakes hay or other light materials into windrows or other formations for drying or baling | http://openfarmtech.org/temp-gvcs-icons/hay-rake.png | |

| Hay Cutter | A device that cuts grass, hay, straw, or other light biomass for haying, baling, or combining | http://openfarmtech.org/temp-gvcs-icons/hay-cutter.png | |

| Backhoe | A piece of excavating equipment or digger consisting of a digging bucket on the end of a two-part articulated arm for digging trenches or large holes | http://openfarmtech.org/temp-gvcs-icons/backhoe.png | |

| Chipper/Hammermill | A machine used for reducing wood or other materials into smaller parts, such as chips or shreds | http://openfarmtech.org/temp-gvcs-icons/chipper-hammermill.png | |

| Trencher | A piece of construction equipment that uses a cutting wheel for digging trenches, laying pipe, cable, or drainage | http://openfarmtech.org/temp-gvcs-icons/trencher.png | |

| Open Source Automobile | A wheeled motor vehicle for transporting people | http://openfarmtech.org/temp-gvcs-icons/automobile.png | |

| Open Source Truck | A larger version of an automobile with a bed for trasporting loads | http://openfarmtech.org/temp-gvcs-icons/truck.png | |

| Dimensional Sawmill | A dimensional sawmill is a circular blade sawmill with 2 blades that is used for producing dimensional lumber in one pass | http://openfarmtech.org/temp-gvcs-icons/sawmill.png | |

| Cement Mixer | A device that homogeneously combines cement, aggregate such as sand or gravel, and water to form concrete | http://openfarmtech.org/temp-gvcs-icons/cement-mixer.png | |

| Well-Drilling Rig | A device for digging deep water wells | http://openfarmtech.org/temp-gvcs-icons/well-drilling-rig.png | |

| Bakery Oven | A device for heating various forms of dough into breads and other baked goods | http://openfarmtech.org/temp-gvcs-icons/industrial-bread-oven.png | |

| Dairy Milker | A device which harvests milk automatically from milk-producing livestock | http://openfarmtech.org/temp-gvcs-icons/milking-machine.png | |

| Electric Motor/Generator | A device that functions as a motor when energized with a voltage, which can also function as an electrical generator when it is spun. | http://openfarmtech.org/temp-gvcs-icons/electric-motor-generator.png | |

| Hydraulic Motors | A mechanical actuator that converts high-pressure fluid flow into rotation | http://openfarmtech.org/temp-gvcs-icons/hydraulic-motor.png | |

| Bioplastic Extruder | An extruder takes a charge of plastic and extrudes a sheet or other profile of useful form, such as greenhouse glazing or water tubing | http://openfarmtech.org/temp-gvcs-icons/plastic-extruder.png | |

| Universal Power Supply | This is a combination power supply for applications from off-grid power to supplying power to welders, induction furnaces, and plasma cutters. | http://openfarmtech.org/temp-gvcs-icons/universal-power-supply.png | |

| Nickel Iron Batteries | Long-life batteries that have a track record of lasting 50 or more years | http://openfarmtech.org/temp-gvcs-icons/nickel-iron-batteries.png |

Other proposed tools

- Loader - an attachment for the LifeTrac tractor

- Village-scale washing machine - powered by the universal rotor

- Fridge - see the page on refrigeration

- Reversible heat pump - for controlling the temperature of homes and greenhouses, refrigerating food and medicine, harnessing solar and geothermal heat

- Stirling engine - transforms heat into mechanical energy

Videos

See a 2 minute video explainer about the GVCS:

Global Village Construction Set in 2 Minutes from Marcin Jakubowski on Vimeo.

This page is about the Global Village Construction Set (GVCS) and the plan for how it will be built by Open Source Ecology. See also:

- H+ Presentation

- Overview presentation at Linz Slides

See latest presentation on the GVCS (as of June, 2010)

Marcin Jakubowski - part 1 from East Bay Pictures on Vimeo.

Economy creates culture and culture creates politics. The politics we seek are freedom, voluntary contract, and human evolution in harmony with life support systems. Note that resource conflicts and overpopulation are eliminated by design. We are after the creation of new society, one which has learned from the past and moves forward with ancient wisdom and modern technology.

This is a real experiment, and product selection is based on us living with the given technologies. First, it is the development of real, economically significant hardware, product, and engineering. Second, this entire set is being compiled into one setting, and land is being populated with the respective productive agents. The aim is to define a new form of social organization where it is possible to create advanced culture, thriving in abundance and largely autonomous, on the scale of a village, not nation or state.

Here is a talk by Marcin Jakubowski on the GVCS at the 4th Oekonux Conference. You can download the slides and see a transcript here.

First is an introduction by Franz Nahrada, leader of the Globally Integrated Village Environment:

Move on to the video on our CEB Story (from the Distillations series):

And here is the main body of the presentation.

The Distillations videos below explain the GVCS and review the progress of 2008-2009.

Click the arrows on the sides to see other videos.

A video presentation on the first year at Factor e Farm and the GVCS from 2007-2008 here.

And you can also view a GVCS slide show presentation for more information.

Collaborative Development Process

The open development process involves global contributions of content to a rigorously defined process for developing, deploying, and improving the Global Village Construction Set. The rigor lies in a template that guides the development through all the necessary theoretical and practical aspects of deploying a given product. The same template, or process, is adapted to deliver all the products of the Construction Set. The template starts with product definition and ends with economically significant models of production.

If you are interested in contributing to this wiki, your first step is a quick debriefing on the issues we are trying to solve. Please bring yourself up to speed with the background, project status, and action items as described in the Development Strategy. Once you read up on the current work and key issues being considered, you are in a position to make meaningful contributions consistent with the goals and progress of the overall project.

With a sufficient pool of technically-skilled collaborators, we aim to deploy the complete Global Village Construction Set in 3 years, starting at the latter part of 2007. The result is a formula for building your own village - whether you pursue our open source designs and business models yourself or with a group, or buy infrastructure components from providers, or buy an entire turnkey village infrastructure according to proven specifications. From that point, all you need is land and people to populate your village, and you are on your way to freedom.

Product Selection Criteria

The selection of 28 products is based on

- Availability of a land or facility base

- Essential contribution to an infrastructure for living and working

- Essential goods and services of wide use and large markets

- Provision of a robust village economy and sufficient surplus for further developments

- Generative nature of the product, thus promoting self-replication of the village

- Selection of a widely applicable and sufficient, but not complete, range of economic activity to support a community

- Viability of a community on a village scale, perhaps 100 people, but as few as 2 or as many as sustained by the land base

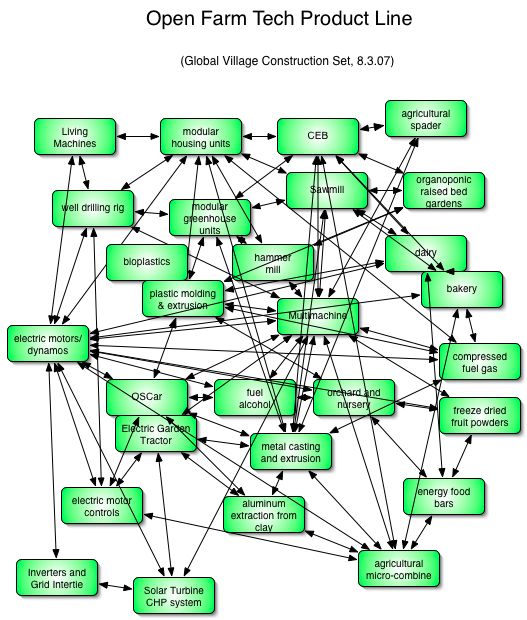

Product Line

Enterprise Community Contract

We are proposing the formation of Global Villages in the form of productive enterprise communities that strive for unprecedented quality of life:

- material abundance

- freedom from bureacracy and unnecessary activity

- total focus on one's true interests

For our particular OSE prototype implementation, we are interested in the following general essence of an Enterprise Community Contract:

- 2 hours of productive activity daily, such that 100% of the community's food, energy, housing, transportation, and technology essentials are produced for subsistence, with surplus production for market

- Agriculture base follows permaculture design, and includes production of water soluble organic fertilizer, orchard, nursery, and crops, as well as certain food processing and value added propositions

- Flexible fabrication produces advanced technologies at the cost of materials

- Cost of living is reduced dramatically, from $20,000/year in the industrialized world, to negligible income requirements, under the assumption of high-tech self-providing

- Each participant undertakes a study program of full stewardship of the community, including:

- Agricultural production capacity

- Technological literacy to operate and maintain flex fab equipment and other machinery

- Numeracy to facilitate design

- Study of the mind and body to expand one's consciousness, skills, and abilities, and to disseminate such human augmentation widely towards eliminating mind control of the masses

- Entry of new people can be negotiated by the new participants providing skills and productive contribution to the community

- Beyond the 2 hour requirement, participants follow a research lifestyle to promote further development of the community or of the greater world

Enabling Technology - Salient Features of Technology Base

Without going into details, the main features for the comprehensive technology base are:

- Hybridization of power devices - decoupling of power source from the working unit in order to produce electrical drive is a formula for increasing integrated efficiency of electromechanical devices such as electric vehicles, tools, heavy equipment, etc. For example, the hybrid car decouples the engine from its wheels by using an electrical generator to feed electric wheel motors. Note that this eliminates the clutch, transmission, crank case and its oil, differential, drive train, and other parts, and replaces these items with electric wire from the generator to electric motor. This is a huge efficiency leap, one in fuel efficiency, and two, in eliminating billions of dollars of industry which is outdated today due to the hybridization option. As such, we can talk of complex machines with huge simplification, assuming easy access to infinitely scaleable and controllable, low cost electric motors (these do not exist today). For example, we can envision an agricultural combine where each moving part is powered by its own electric motor - producing a leap in simplification and maintenance of the overall machine - as all belts, pulleys, gears, and other power transmission components driven by a single engine - are all replaced by electric wire. One can point to many examples where such strategy would provide leapfrog advance in device simplicity and maintenance.

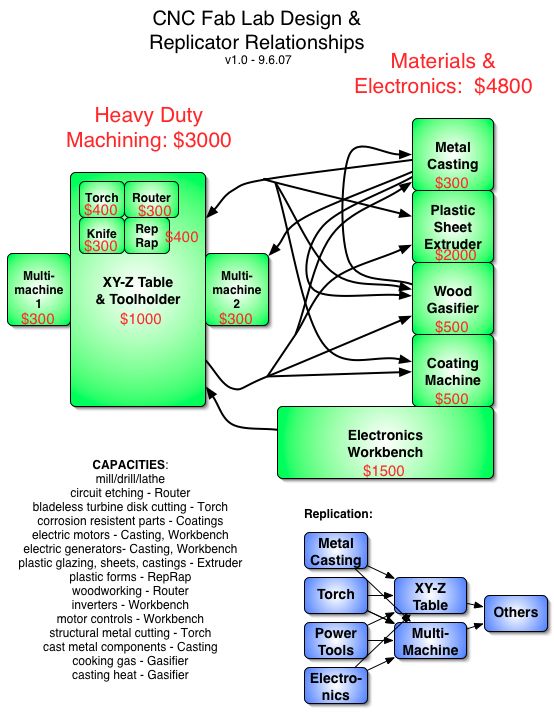

- Solar turbine power generation including heat storage - look at Solar Turbine CHP System

- Open source fab lab - combine and expand the [1] with xyz table as in RepRap (http://reprap.org/), and you can envision a robust fabrication device that integrates open source computer aided design (CAD) and computer aided manufacturing (CAM). This device would perform a large variety of machining and fabrication operations, and would be producible at the cost of materials if metal casting is available. When deployed, we are talking of producing any advanced object or device at the cost of materials. Would you like to fabricate an electric motor for your personal transport vehicle? Here, I'll email you a file to make on your local village fabber. In practice, one could conceptualize a single or several Multimachines, with their milling-drilling-lathing functions, surrounding an xyz motion platform with interchangeable heads. These heads could include acetylene torch attachment, plasma cutter, CO2 laser, router, hot wire, or additive heads such as a plastic extruder found in RepRap. This overall fab lab concept could start with a basic machine such as the Multimachine, with computer controls and table added in time. As such, this is a realistic proposition - with supporting open source knowhow with significant advancement already available. This propels civilization to new levels of decentralized material prosperity, and implies significant reduction of resource conflicts, especially if material feedstocks are sourced locally - as in the next point.

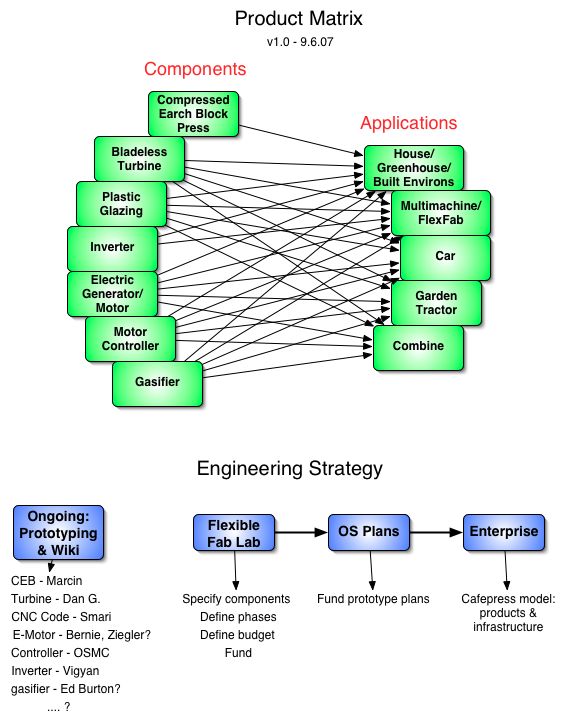

Here is an initial Fab Lab design:

Here is a sample Product Matrix that falls right out of Fab Lab capacities:

- Production of local feedstocks-

- Wood and structural masonry compressed earth block (CEB) for construction - produced from on-site trees and soils

- Compressed Fuel Gas for cooking or melting metal - gas produced from trees

- Bioplastics - such as cellophane from trees

- Biofuels - Fuel Alcohol in temperate zones, palm oil in tropical zones

- Industrial detritus (waste materials) processing - includes Metal Casting and Extrusion or Plastic Extrusion & Molding

- Aluminum Extraction From Clays

Sample Scenario

Imagine a village with buildings of dirt (CEB) with year-round greenhouses (sawmill, CEB, bioplastics from local trees), with all facility energy produced by a solar turbine, where people drive hybrid cars with car bodies (bioplastics) made from local weeds, with critical motors and metal structures (aluminum) extracted from on-site clay, which are fueled by alcohol produced on-site, on a wireless network linked to the greater world. That's just a sampling of the technology base. Food, energy, housing sufficiency. There are no poor among us - because we are all evolving human beings and farmer scientists.

Development Template

The GVCS Development Template, properly adapted, shall be the famework seen when you go into any of the products in the links on top of this page.

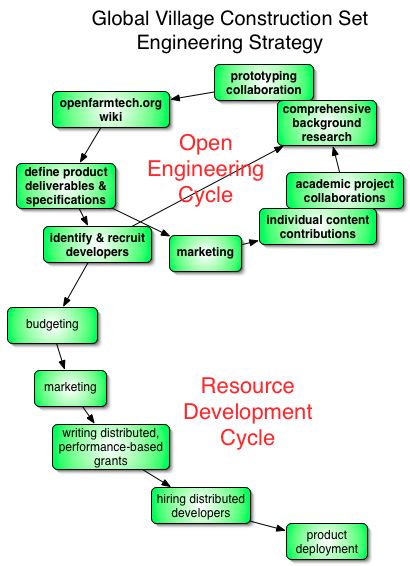

Open Engineering Strategy

Here is a diagram of the engineering development strategy:

Definition of Open Source Hardware and OSE Specifications

See the updated entry for OSE Spec here.

We like to be clear about the meaning of open, or open source,' as used in this work for items of physical production. By open source, we mean documented to the point where one may replicate a given item, without even consulting with the developers. To us, this embodies the most complete form of documentation possible, where sufficient detail is provided to enable independent replication. This is open source embodied in OSE Specifications. Other features of OSE Specificationsare:

- Freely downloadable documentation

- DfD, lifetime design

- Simplicity and low cost are of prime importance

- Replaceable components

- Modular Design

- Scaleability

- Localization

- Level 1 - product fabrication or production is local

- Level 2 - material sourcing is local

- Product evolution - phases and versions are pursued

- Concrete Flexible Fabrication mechanism exists for others to purchase the product at reasonable cost

- Open franchising - replicable enterprise design is available, and training exists for entrepreneurs

Thus, these features are meant to promote liberatory technology - open, replicable, essential, optimal, and ecological goods and services for humankind living in harmony with natural life support systems.

Working Assumptions

Here is a partial list of assumptions that we are making as we go about the development work of this wiki. These assumptions help one to understand our motivations and approach.

- Underlying dynamics of human civilizations are related to peoples' resource base. The resource base, and its control through the control of other humans, is the feedstock for power and its accumulation. Resource conflicts occur because people have not yet learned to manage the global resource base without stealing from others. In other words, society dynamics have not transcended the brute struggle for survival. As a society, we remain on the bottom steps of Maslow's pyramid. Transcending resource conflicts by creation of abundance, on the unit scales of few hundreds to few thousands of humans, is a present possibility under the assumption of open source knowledge flows and advanced technical capacities for material production.

- Today, most humans are controlled not by a commercial force (armies) but by information and social engineering that feeds the commerce itself. Understanding means of social control; understanding the mechanics of one's mind, body, and spirit; learning to discern mechanics of mind control and propaganda as they are used in controlling agendas; and applying learnings to meditation, expansion of consciousness, and evolution of one's awareness and powers are all crucial if civilization is to escape the control of commercialism and is to give up its dependence on a centralized, planned economy.

- Said propaganda and conditioning has successfully removed the notion of self-sufficiency as a viable means of livelihood. Most people are afraid of self-sufficiency and consider it a return to the stone age. Most people cannot envision that advanced civilization can be created in small (100-1000 person), self-sufficient, highly skilled communities. Furthermore, most people do not realize that it is possible to educate, skill, and evolve human beings such that an integrated, self-sufficient lifestyle option that promotes advanced civilization on a small scale of human organization is created. It it possible to achieve this level of excellence if people are taught real knowledge and wisdom, as opposed to undergoing global workforce training.

- Education curricula have typically deleted practical applications deliberately, to produce subjects of the global workforce. If education is reinstated then self-sufficiency will emerge as a natural option.

- Self-sufficiency is not an antisocial behavior, but a means to full individual and community accountability for resource conflicts, foul politics, and other corruptions of large-scale endeavors. (review works of Gandhi, Schumacher, Fuller) Self-sufficiency is a means to highest quality life by definition, one is in control of one's destiny when one is self-sufficient. The assumption of self-sufficiency is that its practitioners must be highly skilled, and not products of centralist education.

- By self-sufficient, we mean in full control of providing one's needs. Note that self-sufficiency refers to needs - those things that allow one to survive in absolute health - and not wants. Self-sufficiency does not imply a solo, isolationist endeavor. Self-sufficiency may be accomplished with the help of as many people as it is possible to maintain full accountability, transparency, and sound ethics within that group. This group may be dispersed globally. Historically, sociology of human settlements has shown that this scale of self-sufficiency is a few hundred people. (see E.F. Schumacher; other references)

- The State promotes well-paid incompetence, largely through specialization, such that subjects produce sufficient surplus to pay for their own oppression.

- Education, media, and social engineering programs have subjugated human integrity to passive consumerism, with its related problems (resource conflicts, loss of freedom such as wage slavery). The only way out of this is creating a framework within which humans can prosper: provision of true education, learning of practical skills, stewardship of land, advanced technology for the people, and open access to economically significant know-how.

- Import substitution is reducing dependence on external feedstocks and replacing them with local ones. People in control of their resources control their own destiny. Thus, to localize the essential parts of an economy completely is the prime formula for social stability. Localization should not be considered a struggle, but merely a possibility. It is a possibility that is not recognized because most people, as specialists, lack integrated technical literacy and skills that make a local economy feasible.

Development

To develop each tool, we go through 15 steps known as the OSE Product Cycle. We develop the technologies one by one, and as the components become available, we add them to the infrastructure of our facility, Factor e Farm.

See also

- Product Ecologies - illustrates how the different components of the GVCS relate with one another