Drill Press: Difference between revisions

No edit summary |

(added LANG template) |

||

| (16 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

{{OrigLang}} | |||

{{GVCS Header}} | |||

=Overview= | |||

[[Image:DrillPress.jpg|thumb|400px|Drill Press]] | |||

A drill press (also known as pedestal drill, pillar drill, or bench drill) is a fixed style of drill that may be mounted on a stand or bolted to the floor or workbench. A drill press consists of a base, column (or pillar), table, spindle (or quill), and drill head, usually driven by an induction motor. The head has a set of handles (usually 3) radiating from a central hub that, when turned, move the spindle and chuck vertically, parallel to the axis of the column. The table can be adjusted vertically and is generally moved by a rack and pinion; however, some older models rely on the operator to lift and reclamp the table in position. The table may also be offset from the spindle's axis and in some cases rotated to a position perpendicular to the column. | |||

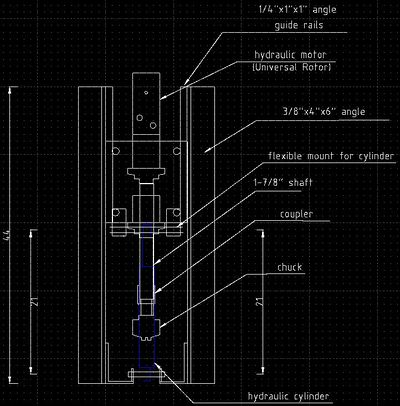

[[Image:drillpressdxf.jpg|400px|thumb|Drill Press CAD. See [http://openpario.mime.oregonstate.edu/projects/drillpress/documents Open Pario ]]] | |||

{{Video}} | |||

==Details== | |||

=Status= | |||

The Drill Press is currently in the prototype phase of design. | |||

= | =See Also= | ||

[[ | *[http://en.wikipedia.org/wiki/Drill Wikipedia:Drill] | ||

*[http://en.wikipedia.org/wiki/Drill#Drill_press Wikipedia: Drill Press] | |||

[[Category:RepLab]] | [[Category:RepLab]] | ||

{{GVCS Footer}} | |||

Latest revision as of 10:32, 9 March 2017

| Drill Press | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

A drill press (also known as pedestal drill, pillar drill, or bench drill) is a fixed style of drill that may be mounted on a stand or bolted to the floor or workbench. A drill press consists of a base, column (or pillar), table, spindle (or quill), and drill head, usually driven by an induction motor. The head has a set of handles (usually 3) radiating from a central hub that, when turned, move the spindle and chuck vertically, parallel to the axis of the column. The table can be adjusted vertically and is generally moved by a rack and pinion; however, some older models rely on the operator to lift and reclamp the table in position. The table may also be offset from the spindle's axis and in some cases rotated to a position perpendicular to the column.

Details

Status

The Drill Press is currently in the prototype phase of design.

See Also