D3D Pro: Difference between revisions

(→Links) |

(→Links) |

||

| (44 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{OrigLang}} | {{OrigLang}} | ||

{{Hint|We now make [[D3D Pro 3]] with an 18" print bed.}} | |||

=Intro= | |||

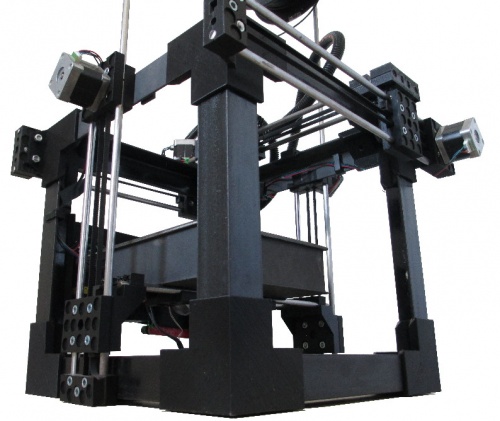

[[File:d3dpro.jpg|500px]] | [[File:d3dpro.jpg|500px]] | ||

'''You can get a ready-to-build kit at https://www.opensourceecology.org/d3d-pro/''' | '''You can get a ready-to-build kit at https://www.opensourceecology.org/d3d-pro/''' | ||

='''Development'''= | |||

{| class="wikitable" | |||

|+ Development Template | |||

! | |||

! Description | |||

! Link to Work Product | |||

! % | |||

|- | |||

! scope=row | | |||

| '''DESIGN''' || || | |||

|- | |||

! scope=row | 1 | |||

| [[Requirements + Value Proposition]] || [[D3D Pro Requirements + Value Proposition]] || {{{1}}} | |||

|- | |||

! scope=row | 2 | |||

| [[Industry_Standards]] || [[D3D Pro Industry Standards]] || {{{2}}} | |||

|- | |||

! scope=row | 3 | |||

| [[Conceptual Design]] || [[D3D Pro Conceptual Design]] || {{{3}}} | |||

|- | |||

! scope=row | 4 | |||

| [[Module Breakdown]] || [[D3D Pro Module Breakdown]] || {{{4}}} | |||

|- | |||

! scope=row | 5 | |||

| [[3D CAD]] || [[D3D Pro 3D CAD]] || {{{5}}} | |||

|- | |||

! scope=row | 6 | |||

| [[Calculations]] || [[D3D Pro Calculations]] || {{{6}}} | |||

|- | |||

! scope=row | 7 | |||

| [[Electronics Design]] || [[D3D Pro Electronics Design]] || {{{7}}} | |||

|- | |||

! scope=row | 8 | |||

| [[Wiring and Plumbing]] || [[D3D Pro Wiring and Plumbing]] || {{{8}}} | |||

|- | |||

! scope=row | 9 | |||

| [[Software]] || [[D3D Pro Software]] || {{{9}}} | |||

|- | |||

! scope=row | | |||

| '''BILL OF MATERIALS || || | |||

|- | |||

! scope=row | 10 | |||

| [[BOM]] || [[D3D Pro BOM]] || {{{10}}} | |||

|- | |||

! scope=row | 11 | |||

| [[vBOM]] || [[D3D Pro vBOM]] || {{{11}}} | |||

|- | |||

! scope=row | 12 | |||

| [[CAM Files]] || [[D3D Pro CAM Files]] || {{{12}}} | |||

|- | |||

! scope=row | 13 | |||

| [[Cut List]] || [[D3D Pro Cut List]] || {{{13}}} | |||

|- | |||

! scope=row | | |||

| '''BUILD''' || || | |||

|- | |||

! scope=row | 14 | |||

| [[Build Instructions]] || [[D3D Pro Build Instructions]] || {{{14}}} | |||

|- | |||

! scope=row | 15 | |||

| [[Fabrication Drawings]] || [[D3D Pro Fabrication Drawings]] || {{{15}}} | |||

|- | |||

! scope=row | 16 | |||

| [[Exploded Part Diagram]] || [[D3D Pro Exploded Part Diagram]] || {{{16}}} | |||

|- | |||

! scope=row | 17 | |||

| [[Production Engineering]] || [[D3D Pro Production Engineering]] || {{{17}}} | |||

|- | |||

! scope=row | | |||

| '''DATA COLLECTION''' || || | |||

|- | |||

! scope=row | 18 | |||

| [[Build Pictures and Video]] || [[D3D Pro Build Pictures and Video]] || {{{18}}} | |||

|- | |||

! scope=row | 19 | |||

| [[Data Collection]] || [[D3D Pro Data Collection]] || {{{19}}} | |||

|- | |||

! scope=row | 20 | |||

| [[Future Work]] || [[D3D Pro Future Work]] || {{{20}}} | |||

|} | |||

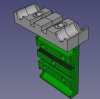

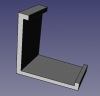

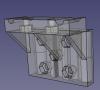

=CAD= | =CAD= | ||

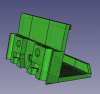

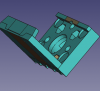

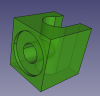

[[File:carriagemotor.png|100px]][[File:yaxisfroma1906.png|100px]][[File:14angleframe.png|100px]][[File:d3d1911xaxis.png|100px]] | [[File:carriagemotor.png|100px]][[File:yaxisfroma1906.png|100px]][[File:14angleframe.png|100px]][[File:d3d1911xaxis.png|100px]] | ||

[[File:assy1.png|100px]][[File:carriagemotor.png|100px]][[File:carriagemotor2.png|100px]][[File:carriagehalfcarriage.png|100px]][[File:frameclip.png|100px]][[File:carriageidler.png|100px]][[File:motorwithclip.png|100px]][[File:idlerwithclip.png|100px]][[File:cableclip.png|100px]][[File:motorwithhanger.png|100px]][[File:d3dcableorg_loop.png|100px]][[File:loomclip.png|100px]] | [[File:assy1.png|100px]][[File:carriagemotor.png|100px]][[File:carriagemotor2.png|100px]][[File:carriagehalfcarriage.png|100px]][[File:frameclip.png|100px]][[File:carriageidler.png|100px]][[File:motorwithclip.png|100px]][[File:idlerwithclip.png|100px]][[File:cableclip.png|100px]][[File:motorwithhanger.png|100px]][[File:d3dcableorg_loop.png|100px]][[File:loomclip.png|100px]][[File:updatedforyconnex.jpg|100px]][[File:updatedgantryfory.jpg|100px]][[File:widenedmotor.png|100px]][[File:widenedidler.png|100px]][[File:truncatedwidenedmotor.png|100px]][[File:autoparallel.png|100px]][[File:withsidehole.png|100px]][[File:xidlerside.png|100px]] | ||

<gallery perrow=6> | <gallery perrow=6> | ||

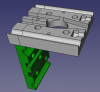

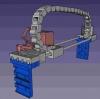

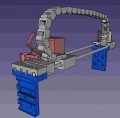

File: | File:updatedgantryfory.jpg|'''Updated gantry for D3D Pro. ''' - FreeCAD -[[File:d3d1911.fcstd]] | ||

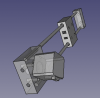

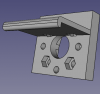

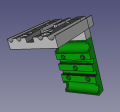

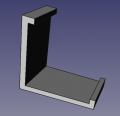

File:14angleframe.png|'''16" Frame ''' - FreeCAD -[[File:frame16.fcstd]] | File:14angleframe.png|'''16" Frame ''' - FreeCAD -[[File:frame16.fcstd]] | ||

| Line 31: | Line 142: | ||

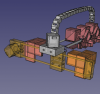

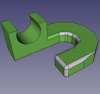

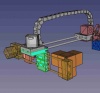

File:yaxisfroma1906.png|'''Y Axis from v19.06.''' - FreeCAD - [[File:yaxisfrom1906.fcstd]]. | File:yaxisfroma1906.png|'''Y Axis from v19.06.''' - FreeCAD - [[File:yaxisfrom1906.fcstd]]. | ||

File: | File:updatedforyconnex.jpg|'''X axis from v19.06.''' - FreeCAD - [[File:xaxisfrom1906.fcstd]]. | ||

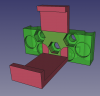

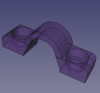

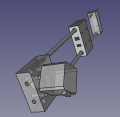

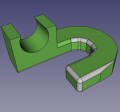

File:carriagemotor.png|'''Carriage motor merge.''' - FreeCAD - [[File:Carriage_motor_merge.fcstd]]. STL - [[File:Carriage_motor_merge.stl]] | File:carriagemotor.png|'''Carriage motor merge.''' - FreeCAD - [[File:Carriage_motor_merge.fcstd]]. STL - [[File:Carriage_motor_merge.stl]] | ||

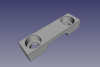

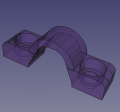

File: | File:xidlerside.png|'''Carriage half-carriage merge.''' - FreeCAD - [[File:Carriage_halfcarriage_merge.fcstd]]. STL - [[File:Carriage_halfcarriage_merge.stl]]. | ||

File:Integrated_carriage.jpg|'''Carriage extruder bracket merge.''' - FreeCAD - [[File:Integrated_carriage.fcstd]]. STL - [[File:Integrated_carriage.stl]] | File:Integrated_carriage.jpg|'''Carriage extruder bracket merge.''' - FreeCAD - [[File:Integrated_carriage.fcstd]]. STL - [[File:Integrated_carriage.stl]] | ||

| Line 44: | Line 155: | ||

File:carriageidler.png|'''Carriage to bed connection.'' - FreeCAD - [[File:Carriage_idler_merge.fcstd]]. STL - [[File:carriagebed.stl]] | File:carriageidler.png|'''Carriage to bed connection.'' - FreeCAD - [[File:Carriage_idler_merge.fcstd]]. STL - [[File:carriagebed.stl]] | ||

File: | File:truncatedwidenedmotor.png|'''Motor side with clip.'' - FreeCAD - [[File:motorwithclip.fcstd]]. STL - [[File:motorwithclip.stl]] | ||

File: | File:widenedidler.png|'''Idler side with clip.'' - FreeCAD - [[File:idlerwithclip.fcstd]]. STL - [[File:idlerwithclip.stl]] | ||

File:cableclip.png|'''Cable clip.'' - FreeCAD - [[File:cableclip.fcstd]]. STL - [[File:cableclip.stl]] | File:cableclip.png|'''Cable clip.'' - FreeCAD - [[File:cableclip.fcstd]]. STL - [[File:cableclip.stl]] | ||

| Line 56: | Line 167: | ||

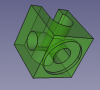

File:spoolholderjoint.jpg|[[File:check.png]]'''Spool Holder.''' File: [[File:spoolholder.stl]] Link for more types of these joints - [https://www.thingiverse.com/thing:2300366] | File:spoolholderjoint.jpg|[[File:check.png]]'''Spool Holder.''' File: [[File:spoolholder.stl]] Link for more types of these joints - [https://www.thingiverse.com/thing:2300366] | ||

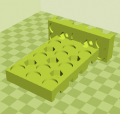

File:withsidehole.png|'''Auto parallel piece.''' File: [[File:autoparallel.fcstd]] [[File:autoparallel.stl]] | |||

</gallery> | </gallery> | ||

| Line 73: | Line 185: | ||

[https://docs.google.com/spreadsheets/d/1rHkfwE_CMwePcAg9vuHtV2jooIJ8hGihrCFGNJlBpog/edit#gid=1571230577 edit] | [https://docs.google.com/spreadsheets/d/1rHkfwE_CMwePcAg9vuHtV2jooIJ8hGihrCFGNJlBpog/edit#gid=1571230577 edit] | ||

Notes: BOM must be updated for Universal Gearless Extruder | |||

==BOM Notes== | |||

*A 4x8 sheet of 16 ga steel weighs 80 lb. | |||

*A 4x8 sheet produces 24 strips of 8' length - or 192' of strip for 24 cuts | |||

*Cutting cost? $1 at [[Metal by the Foot]]? | |||

*A 4x8 costs $114 at Metal by the Foot. | |||

=Quick attach wiring.= | =Quick attach wiring.= | ||

| Line 153: | Line 273: | ||

=Links= | =Links= | ||

*[[D3D v19.06]] - other parts | *[[D3D v19.06]] - other parts | ||

* | *[https://wiki.opensourceecology.org/wiki/Y_Axis_Auto-parallel Y Axis Auto-Parallel] - Details | ||

*[https://www.facebook.com/marcin.jakubowski.378/posts/10217670033399780?hc_location=ufi 120v Heatbed] - detailed assembly photos | |||

=Product= | =Product= | ||

*See [[D3D Pro Product Page]] | *See [[D3D Pro Product Page]] | ||

=Build | =Build Instructions= | ||

<html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vRTZ_J2ZcWe_DxW_thJXiN7v6QCUnfuZvMVb9y3bwAHTTR_NpnPpZFsFAb7qiZK6YomPdz4DXPgzUK5/embed?start=false&loop=false&delayms=3000" frameborder="0" width="408" height="557" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | <html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vRTZ_J2ZcWe_DxW_thJXiN7v6QCUnfuZvMVb9y3bwAHTTR_NpnPpZFsFAb7qiZK6YomPdz4DXPgzUK5/embed?start=false&loop=false&delayms=3000" frameborder="0" width="408" height="557" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | ||

[https://docs.google.com/presentation/d/1r8DquY2ALFOj52tWEXR-pdAAjPTwBV31mBtXbBKX_NI/edit#slide=id.g4303b70038_0_0 edit] | [https://docs.google.com/presentation/d/1r8DquY2ALFOj52tWEXR-pdAAjPTwBV31mBtXbBKX_NI/edit#slide=id.g4303b70038_0_0 edit] | ||

= | =Wiring= | ||

By Irvin: | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10219191144266601&width=500" width="500" height="578" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | |||

= | =Control Panel Wiring and Test= | ||

This is part of a quality control sequence, which requires identificiation of all wires: [[Final_Five_Minute_Control_Panel_Test]] | |||

=Testimonials= | |||

"The most immediate thing I am hoping to use the printer for is actually to do with the pen plotter hack - I'm working on a project where we produce pen plotter drawings generated from code and I thought a universal axis to be a far more flexible solution. -Jon S, UK." | |||

can we get benchmarks/video reviews? | |||

=Links= | =Links= | ||

*'''[[D3D Genealogy]]''' - bleeding edge version as of May, 2020 is [[D3D_v20.04.27]] with 18" print bed. | |||

*Eric's proposal - [[Eric D3D Pro Proposal]] | *Eric's proposal - [[Eric D3D Pro Proposal]] | ||

*[[D3D Pro Order Response]] | |||

*[[D3D Production Records]] | *[[D3D Production Records]] | ||

[[Category: D3D]] | [[Category: D3D]] | ||

*[[D3D_Pro_Product_Release]] | |||

=Hit Counter Added June 3, 2022= | |||

<html><div class="powr-hit-counter" id="62fd9bb1_1654285495"></div><script src="https://www.powr.io/powr.js?platform=html"></script></html> | |||

Latest revision as of 19:45, 3 June 2022

![]() Hint: We now make D3D Pro 3 with an 18" print bed.

Hint: We now make D3D Pro 3 with an 18" print bed.

Intro

You can get a ready-to-build kit at https://www.opensourceecology.org/d3d-pro/

Development

CAD

Updated gantry for D3D Pro. - FreeCAD -File:D3d1911.fcstd

16" Frame - FreeCAD -File:Frame16.fcstd

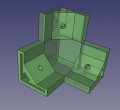

Angle Connector. - FreeCAD with McMaster 6 mm nut -File:Angleconnector.fcstd. Finished STL - File:Anglecorner.stl

Angle Connector with axis mount, left side. - FreeCAD - File:Leftcorner.fcstd. Finished STL - File:Leftcorner.stl

Angle Connector with axis mount, right side. - FreeCAD - File:Rightcorner.fcstd. Finished STL - File:Rightcorner.stl

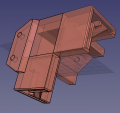

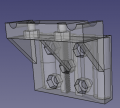

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl

Universal axis carriage: File:Universal axis carriage side.fcstd. STL - File:Universal axis carriage side.stl

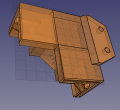

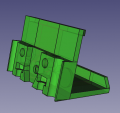

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.

Half carriage: File:Axis half carriage.fcstd. STL - File:Axis half carriage.stl

Y Axis from v19.06. - FreeCAD - File:Yaxisfrom1906.fcstd.

X axis from v19.06. - FreeCAD - File:Xaxisfrom1906.fcstd.

Carriage motor merge. - FreeCAD - File:Carriage motor merge.fcstd. STL - File:Carriage motor merge.stl

Carriage half-carriage merge. - FreeCAD - File:Carriage halfcarriage merge.fcstd. STL - File:Carriage halfcarriage merge.stl.

Carriage extruder bracket merge. - FreeCAD - File:Integrated carriage.fcstd. STL - File:Integrated carriage.stl

Frame clip - FreeCAD - File:Frameclip.fcstd. STL - File:Frameclip.stl

'Carriage to bed connection. - FreeCAD - File:Carriage idler merge.fcstd. STL - File:Carriagebed.stl

'Motor side with clip. - FreeCAD - File:Motorwithclip.fcstd. STL - File:Motorwithclip.stl

'Idler side with clip. - FreeCAD - File:Idlerwithclip.fcstd. STL - File:Idlerwithclip.stl

'Cable clip. - FreeCAD - File:Cableclip.fcstd. STL - File:Cableclip.stl

'Cable clip for end of axis nut catch. - FreeCAD - File:Cableclip2.fcstd. STL - File:Cableclip2.stl

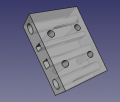

[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl

[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl

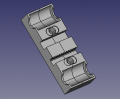

Spool Holder. File: File:Spoolholder.stl Link for more types of these joints - [1]

Spool Holder. File: File:Spoolholder.stl Link for more types of these joints - [1]

Auto parallel piece. File: File:Autoparallel.fcstd File:Autoparallel.stl

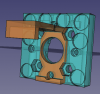

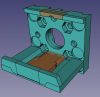

Control Panel

See more at 3D Printer Control Panel

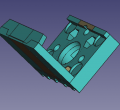

Control Panel - FreeCAD -File:Controlpanel v1904.fcstd. Bent panel STL - File:Bentpanel v1904.stl

BOM

Notes: BOM must be updated for Universal Gearless Extruder

BOM Notes

- A 4x8 sheet of 16 ga steel weighs 80 lb.

- A 4x8 sheet produces 24 strips of 8' length - or 192' of strip for 24 cuts

- Cutting cost? $1 at Metal by the Foot?

- A 4x8 costs $114 at Metal by the Foot.

Quick attach wiring.

Connector 1

| Extruder part | N° | Wire color |

|---|---|---|

| Heat sink fan | 1 | + red |

| 2 | - black | |

| Thermistor | 3 | orange |

| 4 | white | |

| Heater element | 5 | green |

| 6 | yellow | |

| Active cooling fan | 7 | + brown |

| 8 | - blue |

Connector 2

| Extruder part | N° | Wire color |

|---|---|---|

| Z-probe | 1 | brown |

| 2 | blue | |

| 3 | black | |

| Extruder stepper motor | 4 | green |

| 5 | yellow | |

| 6 | orange | |

| 7 | red |

Bugs

- Card slot 3D print - notch too large, card can be pushed in behind the slot

- Get rid of STOP PRINT from menu - can hit it accidentally during long print

- Fix belt hole in carriage to motor

- Fix carriage to idler placement

- Improvement - Flexible surface for popping prints right off

Links

- D3D v19.06 - other parts

- Y Axis Auto-Parallel - Details

- 120v Heatbed - detailed assembly photos

Product

Build Instructions

Wiring

By Irvin:

Control Panel Wiring and Test

This is part of a quality control sequence, which requires identificiation of all wires: Final_Five_Minute_Control_Panel_Test

Testimonials

"The most immediate thing I am hoping to use the printer for is actually to do with the pen plotter hack - I'm working on a project where we produce pen plotter drawings generated from code and I thought a universal axis to be a far more flexible solution. -Jon S, UK."

can we get benchmarks/video reviews?

Links

- D3D Genealogy - bleeding edge version as of May, 2020 is D3D_v20.04.27 with 18" print bed.

- Eric's proposal - Eric D3D Pro Proposal

- D3D Pro Order Response

- D3D Production Records

- D3D_Pro_Product_Release

![[10] Motor Side of Axis - 221k - FreeCAD -File:Universal axis motor side.fcstd. STL - File:Universal axis motor side.stl](/images/thumb/4/45/Motorside.jpg/120px-Motorside.jpg)

![[10] Short Idler Side - 75k - FreeCAD - File:Universal Axis Idler Side short version.fcstd. STL - File:Universal Axis Idler Side short version.stl.](/images/thumb/a/ae/Idlershort.jpg/120px-Idlershort.jpg)

![[10] Belt Holding Peg - FreeCAD original size - File:Peg 8mm rods.fcstd. STL at 85% size, works well - File:Peg 8mm rods.stl](/images/thumb/a/a5/Peg85.jpg/120px-Peg85.jpg)

![Spool Holder. File: File:Spoolholder.stl Link for more types of these joints - [1]](/images/thumb/d/d6/Spoolholderjoint.jpg/120px-Spoolholderjoint.jpg)