CNC Circuit Mill: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

='''1''' Research and Development= | |||

http://opensourceecology.org/wiki/CNC_Circuit_Mill/Research_Development | |||

='''1''' Manufacturing Instructions= | |||

http://opensourceecology.org/wiki/CNC_Circuit_Mill/Manufacturing_Instructions | |||

='''1''' User's Manual= | |||

http://opensourceecology.org/wiki/CNC_Circuit_Mill/User's_Manual | |||

=Set Aside for Experimental Development in Open-Source Documentation Organization= | |||

{{GVCS Header}} | {{GVCS Header}} | ||

Revision as of 00:19, 28 December 2011

1 Research and Development

http://opensourceecology.org/wiki/CNC_Circuit_Mill/Research_Development

1 Manufacturing Instructions

http://opensourceecology.org/wiki/CNC_Circuit_Mill/Manufacturing_Instructions

1 User's Manual

http://opensourceecology.org/wiki/CNC_Circuit_Mill/User's_Manual

Set Aside for Experimental Development in Open-Source Documentation Organization

| CNC Circuit Mill | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

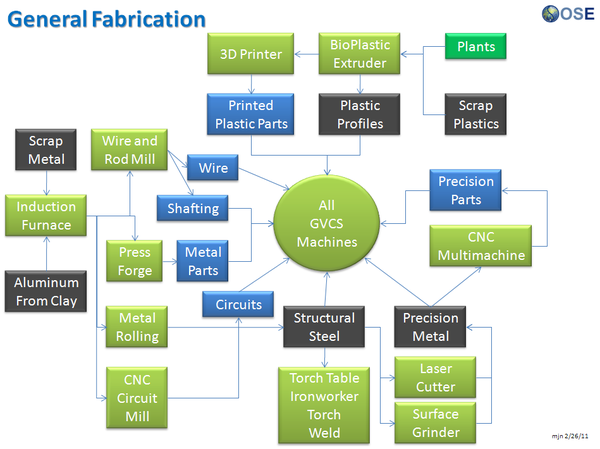

CNC Circuit Mill enables automated production of electronic circuit boards. As a GVCS technology it enables automation functionality.

CNC Circuit Mill enables automated production of electronic circuit boards. As a GVCS technology it enables automation functionality.

Detailed Description

Printed circuit board milling is the process of removing areas of copper from a sheet of printed circuit board material to recreate the pads, signal traces and structures according to patterns from a digital circuit board plan known as a layout file. Similar to the more common and well known chemical PCB etch process, the PCB milling process is subtractive: material is removed to create the electrical isolation and ground planes required. However, unlike the chemical etch process, PCB milling is typically a non-chemical process and as such it can be completed in a typical office or lab environment without exposure to hazardous chemicals. High quality circuit boards can be produced using either process. In the case of PCB milling, the quality of a circuit board is chiefly determined by the system's true, or weighted, milling accuracy and control as well as the condition (sharpness, temper) of the milling bits and their respective feed/rotational speeds. By contrast, in the chemical etch process, the quality of a circuit board depends on the accuracy and/or quality of the photomasking and the state of the etching chemicals.

Product Ecology

Uses

Laser Cutter - Structure

Laser Cutter - Structure Induction Furnace - Router, spindle

Induction Furnace - Router, spindle Multimachine - spindles

Multimachine - spindles Electric Motor Generator - XYZ articulation

Electric Motor Generator - XYZ articulation Rod and Wire Mill - Wires

Rod and Wire Mill - Wires Universal Power Supply - Power

Universal Power Supply - Power

Creates

- Circuit boards

Universal Power Supply boards

Universal Power Supply boards- Controllers

See Product Ecologies for more information.

Components

- XYZ Table

- Motors

- Wires

- Controller

- Router

- Vacuum

Status

The CNC Circuit mill is currently in the Research Phases of Product Development.

See Also

- CNC Circuit Mill Discussion

- CNC Circuit Mill Concept

- Stepper Motor

- Comparison of CNC kits

- Mantis 9

- Snaplock

- Shapeoko