Induction Furnace: Difference between revisions

(Added some more links under the "External Links" section) |

|||

| (31 intermediate revisions by 11 users not shown) | |||

| Line 1: | Line 1: | ||

{{OrigLang}} | |||

{{GVCS Header}} | {{GVCS Header}} | ||

{{Template:Category=Induction furnace}} | {{Template:Category=Induction furnace}} | ||

=Overview= | |||

== | |||

[[Image:InductionFurnace.png|right|400px|[[Induction Furnace]]]] | |||

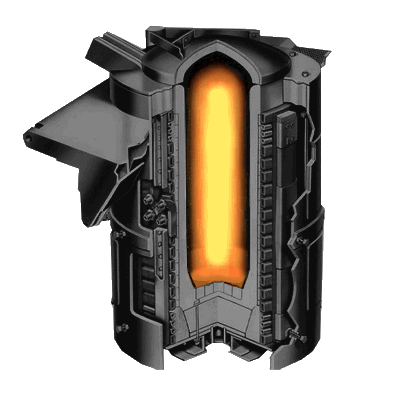

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. | |||

{{Video}} | |||

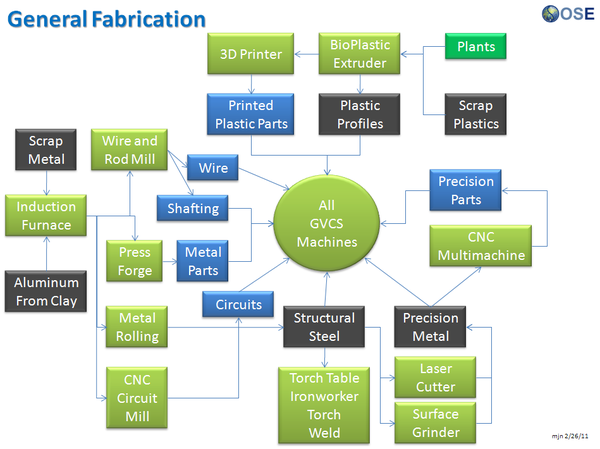

[[Image:2b-Genfabecology.png|600px|right]] | |||

=Requirements= | |||

*Meets [[OSE Specifications]] | |||

*Modular in power units of 5 or 10 kW | |||

*Microcontroller-driven - ideally an Arduino brain with power elements | |||

=Details= | |||

The advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting. Most modern foundries use this type of furnace and now also more iron foundries are replacing cupolas with induction furnaces to melt cast iron, as the former emit lots of dust and other pollutants. Induction furnace capacities range from less than one kilogram to one hundred tonnes capacity and are used to melt iron and steel, copper, aluminium and precious metals. Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements.[1] The one major drawback to induction furnace usage in a foundry is the lack of refining capacity; charge materials must be clean of oxidation products and of a known composition and some alloying elements may be lost due to oxidation (and must be re-added to the melt). | |||

Operating frequencies range from utility frequency (50 or 60 Hz) to 400 kHz or higher, usually depending on the material being melted, the capacity (volume) of the furnace and the melting speed required. Generally, the smaller the volume of the melts, the higher the frequency of the furnace used; this is due to the skin depth which is a measure of the distance an alternating current can penetrate beneath the surface of a conductor. For the same conductivity, the higher frequencies have a shallow skin depth - that is less penetration into the melt. Lower frequencies can generate stirring or turbulence in the metal. | |||

A preheated, 1-tonne furnace melting iron can melt cold charge to tapping readiness within an hour. Power supplies range from 10 kW to 15 MW, with melt sizes of 20 kg to 30 tonne of metal respectively. | |||

An operating induction furnace usually emits a hum or whine (due to magnetostriction), the pitch of which can be used by operators to identify whether the furnace is operating correctly or at what power level. | |||

== | =Development Notes= | ||

Read a commercial description of an induction furnace [http://www.voltamptransformers.com/induction_furnace_trans.html from Voltamptransformers] | |||

[ | |||

Read about 3-phase electrical power [https://en.wikipedia.org/wiki/Three-phase_electric_power at its wikipage] | |||

[ | Read about 3-phase electrical standards in north America [http://www.control.com/thread/999290407 at control.com forums] | ||

== | =Product Ecology= | ||

'''Uses''' | |||

* | *{{UPS}} - Power | ||

'''Creates''' | |||

*[[Steel]] - [[GVCS]] (pretty much every machine depends on this) | |||

* [ | |||

See [[Product Ecologies]] for more information. | |||

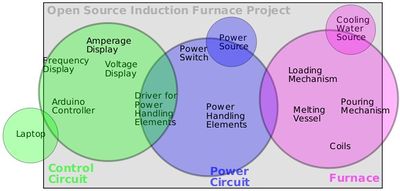

= | =Components= | ||

[[Image:InductionComponents.jpg|400px|right]] | |||

*Induction Furnace Circuit | |||

*Heat Dissipation System | |||

*Coil | |||

*Melt Chamber | |||

*Feeder | |||

*Crucible | |||

=Status= | |||

The '''Induction Furnace''' is currently in the [[Induction Furnace/Research Development research phase of product development]]. | The '''Induction Furnace''' is currently in the [[Induction Furnace/Research Development|research phase of product development]]. | ||

= | =Internal Links= | ||

*[[Spectrometer]] | *[[Spectrometer]] | ||

*[[Foundry]] | *[[Foundry]] | ||

=External Links= | |||

*[http://en.wikipedia.org/wiki/Induction_furnace Wikipedia: Induction Furnace] | |||

*[http://en.wikipedia.org/wiki/Investment_casting Wikipedia: Investment Casting] | |||

*[https://www.bostonmetal.com/moe-technology/ Molten Oxide Electrolysis - carbon free process that goes directly from ore to pure metal with pure oxygen as a byproduct] | |||

*[https://www.nasa.gov/feature/molten-oxide-electrolysis/ NASA's page on MOE] | |||

*[https://www.youtube.com/watch?v=-pYNzxorJs0 Youtube: Better Metal from Bill Gates youtube channel] | |||

*[https://www.youtube.com/watch?v=pg5M5WjGx5M Youtube: Donald Sadoway at EmTech MENA 2019: Steel Production without Co2 Emissions] | |||

*[https://www.youtube.com/watch?v=DbZZD6J_AK0 An Open Source Design for a 3kw Induction Heater] | |||

[[Category:Induction Furnace]] | [[Category:Induction Furnace]] | ||

Latest revision as of 00:22, 17 March 2021

| Induction Furnace | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Main > Digital Fabrication > RepLab Tools > Induction furnace

Overview

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal.

Requirements

- Meets OSE Specifications

- Modular in power units of 5 or 10 kW

- Microcontroller-driven - ideally an Arduino brain with power elements

Details

The advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting. Most modern foundries use this type of furnace and now also more iron foundries are replacing cupolas with induction furnaces to melt cast iron, as the former emit lots of dust and other pollutants. Induction furnace capacities range from less than one kilogram to one hundred tonnes capacity and are used to melt iron and steel, copper, aluminium and precious metals. Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements.[1] The one major drawback to induction furnace usage in a foundry is the lack of refining capacity; charge materials must be clean of oxidation products and of a known composition and some alloying elements may be lost due to oxidation (and must be re-added to the melt).

Operating frequencies range from utility frequency (50 or 60 Hz) to 400 kHz or higher, usually depending on the material being melted, the capacity (volume) of the furnace and the melting speed required. Generally, the smaller the volume of the melts, the higher the frequency of the furnace used; this is due to the skin depth which is a measure of the distance an alternating current can penetrate beneath the surface of a conductor. For the same conductivity, the higher frequencies have a shallow skin depth - that is less penetration into the melt. Lower frequencies can generate stirring or turbulence in the metal. A preheated, 1-tonne furnace melting iron can melt cold charge to tapping readiness within an hour. Power supplies range from 10 kW to 15 MW, with melt sizes of 20 kg to 30 tonne of metal respectively.

An operating induction furnace usually emits a hum or whine (due to magnetostriction), the pitch of which can be used by operators to identify whether the furnace is operating correctly or at what power level.

Development Notes

Read a commercial description of an induction furnace from Voltamptransformers

Read about 3-phase electrical power at its wikipage

Read about 3-phase electrical standards in north America at control.com forums

Product Ecology

Uses

Universal Power Supply - Power

Universal Power Supply - Power

Creates

See Product Ecologies for more information.

Components

- Induction Furnace Circuit

- Heat Dissipation System

- Coil

- Melt Chamber

- Feeder

- Crucible

Status

The Induction Furnace is currently in the research phase of product development.

Internal Links

External Links

- Wikipedia: Induction Furnace

- Wikipedia: Investment Casting

- Molten Oxide Electrolysis - carbon free process that goes directly from ore to pure metal with pure oxygen as a byproduct

- NASA's page on MOE

- Youtube: Better Metal from Bill Gates youtube channel

- Youtube: Donald Sadoway at EmTech MENA 2019: Steel Production without Co2 Emissions

- An Open Source Design for a 3kw Induction Heater