Backhoe

Overview

The Backhoe is a piece of excavating equipment used for digging holes and trenches.

Versions

Backhoe 4

No real plans for Backhoe 4 as of Oct 2013. That's just a place to record ideas for a future version.

Backhoe 3

Under active development as of Oct 2013

Backhoe 2

Plans and photos from the 6 in 60 campaign. See Cory Shenk Log for iterations of the design.

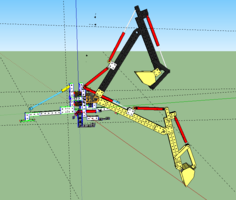

- This is the most recent version of the backhoe that I have upon the end of 6 in 60: File:Backhoe deep dig.skp

- We were never able to completely build it but we did complete sections and components. Check Leandra's Log and Luca's Log for any other information. We spent a decent chunk of time working on these together.

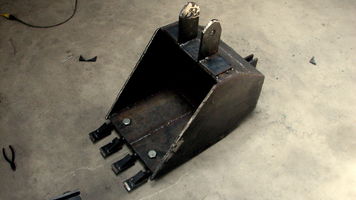

Bucket

- Parts for the body of the bucket. I used three pieces that were 4 inches wide as you can see in the photo. Two should be replaced with an 8 inch wide piece of the same length. It reduces the amount of welding required and adds strength to the bucket.

- You can see two pieces have already been welded. This should be cut out of one piece of steel.

- I allowed myself extra room on the pieces that I cut for the sides of the bucket. This allowed some wiggle room when assembling the entire thing.

- Step by Step in Photos

- The connection points should be revisited for better attachment to the stick. See Stick Design.

- There was often physical conflict where points attached that had square corners (in the case of the bucket and in other areas, usually cylinders). It might be a good practice to simply always notch them off or round the corners with the torch, or fabricate a rounded blade for the iron worker.

- The teeth of the bucket are bolted on so that they can easily be removed. This seems unnecessary, especially in a final version.

- I cannot determine how the shape of the bucket will affect its performance. This will need to looked into upon completion.

Stick

- Although we never reached the point of assembling the entire Boom and Stick to the Pivot, my guess (based off of many experiences in that workshop) is that there would have been conflict with the bolts and cylinders within the range of motion.

- To limit the amount of times that this occurs it would be beneficial to draw very exact models of bolts, washers, nuts, etc. Included with these should also be cylinders of various sizes, especially the sizes that would be used frequently.

- One variable that would be tricky account for is the way that beams and plates fit together.

- Is it possible to create warehouse pieces that include variables like these?

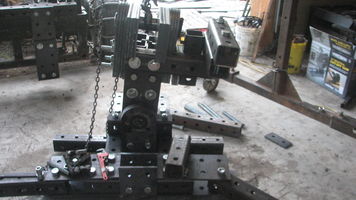

- 1

- 2

- 3

- As you can see in photos 1, 2, and 3, the triangular design that allows greater range of motion for the bucket had to be made wide to clear the bolts. This resulted in a lot of side to side movement of these pieces which is not ideal, especially under load.

- One possible solution would be to weld the two beams instead of bolting. This would allow the triangular component to rotate along the side of the stick, reducing the play.

- 4

- If bolts are still used then the method of connecting the pieces needs to be addressed. We used threaded rod because we were in a rush and did not have the proper materials on hand. Threaded rod is decidedly weaker than a smooth rod. A tractor pin, or its equivalent, would be better, but it is still a great distance to span.

- 5

- This design employs 4 points of rotation. I was attempting to mimic the designs that I found in most commercial backhoes.

- 6

- 7

- Here are some photos that I referenced from a quick Google search:

Pivot

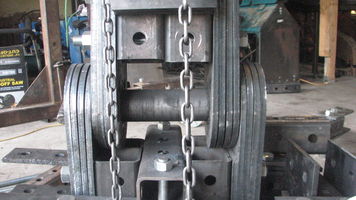

Cylinder - [1]

- The greatest difficulty with the pivot (and every other component we tried to build) was that the holes did not line up which made assembly difficult. The pivot had many areas that required bolts to pass through along with two three inch pins. This exacerbated the problem.

- We found that the best way to assemble was to build the pivot plates AROUND the pin and then bolt the plates to the corresponding tubing.

- The collars cut for the pivot plate were slightly different in width. This caused an irregularity in plate width once they were welded in place.

- The greatest challenge that we had with the pivot was coming up with a design to make the pivot move from side to side. Commercial backhoes have a cylinder that runs in between the top and bottom of the pivot and connects to a "C" shaped piece. Due to lack of time we were not able to come up with anything that would mimic this in design or functionality.

For the Future

- make sure the holes align

- build around the pin

- streamline the pivot (it is very heavy)

- Design with side to side motion in mind

Backhoe 1

Main page for the Backhoe 1.

Details

They are typically mounted on the back of a tractor or front loader, this one is mounted on a LifeTrac. It consists of a digging bucket on the end of a two-part articulated arm. The section of the arm closest to the vehicle is known as the boom, and the section which carries the bucket is known as the dipper or dipperstick (the terms "boom" and "dipper" having been used previously on steam shovels). The boom is attached to the vehicle through a pivot known as the kingpost, which allows the arm to slew left and right, usually through a total of around 200 degrees. Modern backhoes are powered by hydraulics.

The backhoe is one of the most basic dirt working tools and is a common attachment to many small tractor and skid-steer vehicles. It can be used for digging trenches for foundations, digging up material to make compressed earth blocks, digging waste pits, and many other common building/farming tasks. Furthermore, by attaching a chain to the bucket, the backhoe can be used to lift and transport heavy loads such as engine blocks, battery packs, long pieces of pipe, etc.

Commercially manufactured backhoes vary greatly in their size and capabilities and therefore vary significantly in price. A quick google search seems to indicate that relatively small, simple devices like the one we are considering range from 2 to 4 thousand dollars with more sophisticated attachments approaching 10 thousand dollars.

Product Ecology

Made with

Creates

Videos

See Also