Sawmill: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| (171 intermediate revisions by 15 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{OrigLang}} | ||

{{GVCS Header}} | |||

= | ==Overview== | ||

A sawmill converts felled logs from trees into green wood lumber. As a piece of the [[GVCS]], it unlocks a range of well-established wood construction techniques. | |||

To convert the green wood into finished dried lumber the cut boards are either [[kiln| air-dried]] or fired in a [[kiln]]. | |||

==Detailed Description== | |||

<html> | |||

<iframe src="https://player.vimeo.com/video/28369397?title=0&byline=0&portrait=0" width="400" height="233" frameborder="0"></iframe> | |||

</html> | |||

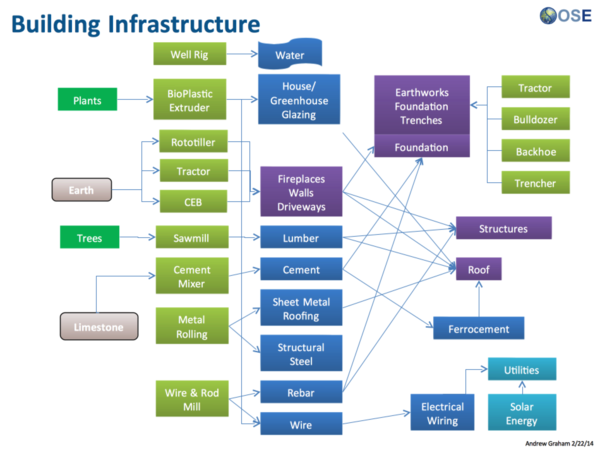

==Product Ecology== | |||

[[Image:4b-Constructioneco.png|600px|right]] | |||

{{Product Ecology | |||

= | |Product={{Sawmill}} | ||

|From= | |||

* {{Furnace}} | |||

* {{Welder}} | |||

* {{Multimachine}} | |||

* {{Hydraulic Motor}} | |||

= | |Uses= | ||

* [[Wood]] | |||

* {{PowerCube}} | |||

|Creates= | |||

* [[Sawdust]] | |||

* [[Lumber]] | |||

= | |Enables= | ||

* {{Pelletizer}} | |||

* {{Hammermill}} | |||

* [[Kiln]] | |||

* [[Workshop]] | |||

* [[Greenhouse]] | |||

* [[Hab Lab]] | |||

* [[RepLab]] | |||

|Components= | |||

*Blade | |||

*Structure | |||

*Bed | |||

*Gantry | |||

*Bearings | |||

*[[Hydraulic Hoses]] | |||

*[[Control Box]] | |||

}} | |||

[[Image: | ==Status== | ||

[[Image:Sawmill2.jpg|right]] | |||

The first Sawmill prototype is currently under construction as a part of the [[GVCS Rollout Plan]]. | |||

[[ | See [[Dimensional_Sawmill_Prototype_I]] for in-progress videos. | ||

==Videos== | |||

{{video}} | |||

== | ==See Also== | ||

*[[Sawmill - Design Rationale]] | |||

*[[Sawmill Design]] | |||

*[[Sawmill Analysis]] | |||

*[[Sawmill/Research_Development|Research]] | |||

*[[Sawmill Archive]] | |||

*[[Cut-to-Length Logging]] | |||

*[[Wood]] | |||

*[[Forest]] | |||

*[[Kiln]] | |||

==Links== | |||

* [http://en.wikipedia.org/wiki/Sawmill Wikipedia: Sawmill] | |||

* [http://en.wikipedia.org/wiki/Portable_sawmill Wikipedia: Portable Sawmill] | |||

' | ===Theo's Github Repository=== | ||

https://github.com/Veradrix90/Dimensional-Sawmill | |||

{{GVCS Footer}} | |||

{ | |||

Latest revision as of 05:50, 21 November 2025

| Sawmill | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

A sawmill converts felled logs from trees into green wood lumber. As a piece of the GVCS, it unlocks a range of well-established wood construction techniques.

To convert the green wood into finished dried lumber the cut boards are either air-dried or fired in a kiln.

Detailed Description

Product Ecology

| From | Uses | Creates | Enables |

|---|---|---|---|

|

Components

|

Status

The first Sawmill prototype is currently under construction as a part of the GVCS Rollout Plan.

See Dimensional_Sawmill_Prototype_I for in-progress videos.

Videos

See Also

- Sawmill - Design Rationale

- Sawmill Design

- Sawmill Analysis

- Research

- Sawmill Archive

- Cut-to-Length Logging

- Wood

- Forest

- Kiln

Links

Theo's Github Repository

https://github.com/Veradrix90/Dimensional-Sawmill