Ironworker: Difference between revisions

(Adding version-specific pages) |

No edit summary |

||

| Line 25: | Line 25: | ||

TODO | TODO | ||

=Details= | =Details= | ||

TODO | |||

=Product Ecology= | =Product Ecology= | ||

''' | '''Uses''' | ||

*{{ | *{{Furnace}} Steel | ||

*{{Welder}} parts | |||

*{{Welder}} | |||

'''Creates''' | '''Creates''' | ||

* | *{{CEB}} arm holes | ||

*{{LifeTrac}} treads and plate holes | |||

See [[Product Ecologies]] for more information. | |||

=See Also= | =See Also= | ||

*[[ | *[[Hole Puncher Die]] | ||

*[[120 Ton Hole Puncher]] | |||

*[http://blog.opensourceecology.org/2010/07/open-source-150-ton-hole-puncher/ Blog Announcement] | |||

[[Category:Backhoe]] | [[Category:Backhoe]] | ||

| Line 85: | Line 82: | ||

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdHkxTUF5QUs1aEswTzY5QlRnRG52Mmc#gid=0 | https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdHkxTUF5QUs1aEswTzY5QlRnRG52Mmc#gid=0 | ||

==Details== | ==Details== | ||

| Line 96: | Line 90: | ||

<iframe src="https://player.vimeo.com/video/13566199?title=0&byline=0&portrait=0" width="400" height="233" frameborder="0"></iframe> | <iframe src="https://player.vimeo.com/video/13566199?title=0&byline=0&portrait=0" width="400" height="233" frameborder="0"></iframe> | ||

</html> | </html> | ||

==Components== | ==Components== | ||

| Line 123: | Line 105: | ||

The Ironworker is currently in the [[Ironworker/Research_Development| prototyping phase of product development]], with hole-puncher and press variants in active use for [[CEB Press]] and [[PowerCube]] fabrication. Future prototypes aim to integrate shearing capabilities and solenoid controls. | The Ironworker is currently in the [[Ironworker/Research_Development| prototyping phase of product development]], with hole-puncher and press variants in active use for [[CEB Press]] and [[PowerCube]] fabrication. Future prototypes aim to integrate shearing capabilities and solenoid controls. | ||

[[Category:RepLab]] | [[Category:RepLab]] | ||

Revision as of 20:52, 24 October 2013

Overview

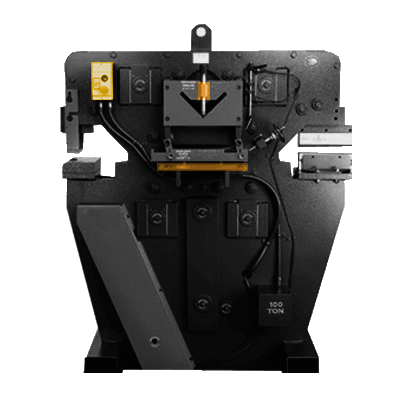

An Ironworker is the amalgamation of 5 machines clubbed into a single engineering wonder, forming the backbone of many fabrication workshops. An Ironworker comprises of a punching machine, a plate shear, a section shear, a punch and shear machine and a coper-notcher.

Generating force using hydraulic systems or mechanical leverage, Ironworker machines can shear, punch holes and notch in steel plates.

Versions

Ironworker 3

Main page for the Ironworker 3.

Under active development as of Oct 2013

Ironworker 2

TODO

Ironworker 1

TODO

Details

TODO

Product Ecology

Uses

Induction Furnace Steel

Induction Furnace Steel Welder parts

Welder parts

Creates

See Product Ecologies for more information.

See Also

| Ironworker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Latest IronWorker file (June 6, 2013)

File:IronworkerBOM.skp

(This file also contains the Bill of Materials as the design currently stands.)

Ironworker Prototype II

See corresponding blog post - [1]

Spreadsheet of Links

https://docs.google.com/spreadsheet/ccc?key=0AlpsBarfpPkzdHkxTUF5QUs1aEswTzY5QlRnRG52Mmc#gid=0

Details

Sketchup of prototype 1:

Components

- Structural Steel

- Pins

- Hydraulic Ram

- Controls

- Ironworking

- Press

- Punch - Die

- Shear

- Notcher

Status

The Ironworker is currently in the prototyping phase of product development, with hole-puncher and press variants in active use for CEB Press and PowerCube fabrication. Future prototypes aim to integrate shearing capabilities and solenoid controls.