CNC Torch Table: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 3: | Line 3: | ||

==Overview== | ==Overview== | ||

[[Image:TorchTable.png|thumb|400px|Torch Table]] | [[Image:TorchTable.png|thumb|400px|Torch Table]] | ||

[[Image:CNC Torch Tablepic.jpg|thumb|right|400px]] | |||

The CNC Torch Table is a table capable of cutting designs out of metal with a 2-axis torch controlled by computer. | The CNC Torch Table is a table capable of cutting designs out of metal with a 2-axis torch controlled by computer. | ||

| Line 14: | Line 16: | ||

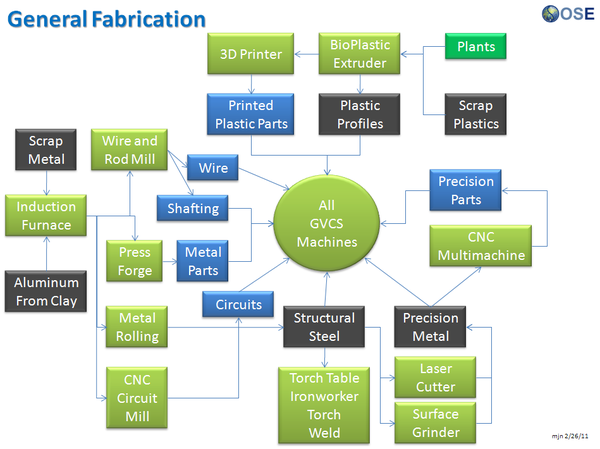

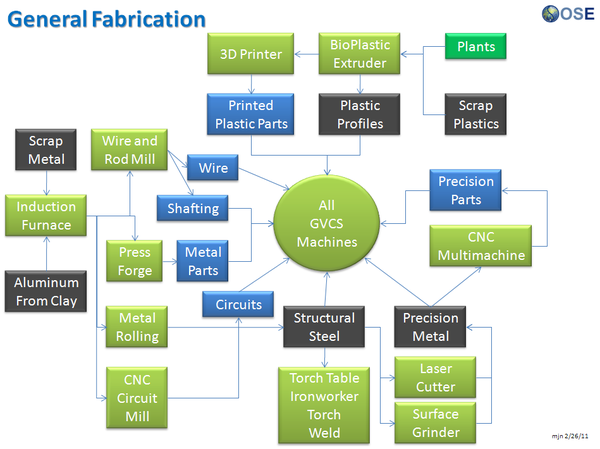

==Product Ecology== | ==Product Ecology== | ||

[[Image:2b-Genfabecology.png|600px|thumb|General Fabrication [[Product Ecology]]]] | |||

'''Made with''' | '''Made with''' | ||

*[[Induction Furnace]] - Steel | *[[Induction Furnace]] - Steel | ||

| Line 23: | Line 28: | ||

*[[QA Plates]] | *[[QA Plates]] | ||

See [[Product Ecologies]] for more information. | See [[Product Ecologies]] for more information. | ||

Revision as of 20:13, 19 September 2011

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The CNC Torch Table is a table capable of cutting designs out of metal with a 2-axis torch controlled by computer.

The CNC Torch Table provides a quicker solution for cutting sheet metal, especially into intricate patterns that are difficult to cut by hand.

Description

Product Ecology

General Fabrication Product Ecology

Made with

- Induction Furnace - Steel

- Multimachine - Precision Guides, bearings

Creates

See Product Ecologies for more information.

Components

Specifications

Status

Currently on Prototype I, working with incorporating features into in OSE production runs.

Prototype II

- First step: perfection of mechanical design for replicability to 1/32" over 4x8' area

- Need open source controller, end stops, and z height automation/detection.

- We could use existing structure, with modifications. Right now we use gear rack. We can simplify the carriage structure.

- If we want to go all out - we could use full gas flow control - but that is probably beyond the scope of the present program - as it would require expensive parts until we can manufacture them ourselves.

- Open source stepper motors would be a good addition - if we could find somebody to design/fab them - that would be great.

- Computer vision for fully automated cutting would be the last step.

- Next steps: stiffening frame design to accommodate router heads

See Also