D3D Mega v23.05: Difference between revisions

Jump to navigation

Jump to search

mNo edit summary |

(→Links) |

||

| (8 intermediate revisions by the same user not shown) | |||

| Line 6: | Line 6: | ||

|titlestyle = | |titlestyle = | ||

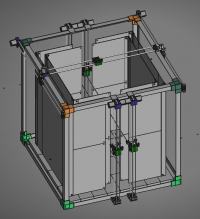

|image = [[File: | |image = [[File:D3D_Mega_v23.05.png|200px|alt=D3D Mega v23.05]] | ||

|imagestyle = | |imagestyle = | ||

|caption = Short description | |caption = Short description | ||

| Line 39: | Line 39: | ||

|data8 = [[Universal Frame]] system | |data8 = [[Universal Frame]] system | ||

|header9 = | |header9 = | ||

|label9 = | |label9 = Module 6 | ||

|data9 = | |data9 = [[Heated Bed Chamber]] system | ||

|header10 = | |header10 = | ||

|label10 = | |label10 = Key Specification | ||

|data10 = | |data10 = Scaled to 2' bed size using the 8 mm [[Universal Axis]]. | ||

|header11 = | |header11 = | ||

|label11 = Productivity | |label11 = Construction | ||

| | |data11 = Steel frame with 3D printed corners are used to hang the Universal Axis. Steel-plastic assemblies are used throughout, using 3D printed plastic for complex geometries and steel for strength. | ||

| | |header12 = | ||

|label12 = Productivity | |||

|data12 = Best-in-class heatbed for speed of heating and temperature (up to 178C). Best-in-class extruder for print speed using rubber (in addition to thermoplastics). Current productivity is 5 lb/24 hr print rate per print head. Features ready scalability to 20 lb/day print rate using the [[Supervolcano Nozzle]]. Features scalability to 4-9 print heads for an 80-180 lb/day print rate. | |||

|header13 = Completion Status | |||

|label13 = | |label13 = | ||

|data13 = This fork of the D3D Mega is designed to use multiple 8mm Universal Axes paired together for additional strength on the Z axis, enabling a larger bed size while still using the easy to source and build 8mm axis. | |data13 = Currently not yet built | ||

|header14 = | |||

|label14 = | |||

|data14 = This fork of the D3D Mega is designed to use multiple 8mm Universal Axes paired together for additional strength on the Z axis, enabling a larger bed size while still using the easy to source and build 8mm axis. | |||

| | |header15 = Next Steps | ||

|label15 = | |label15 = | ||

|data15 = Product releases of [[D3D Pro 2]] (12" print bed) and [[D3D Pro 3]] (18" print bed), as well as developing the 4x4x8" 3D printer + [[OSE Shredder]] + [[OSE Filament Maker]] to solve the plastic waste issue. OSE's solution is distributed production of construction materials such as plastic lumber and other large objects from waste plastic feedstocks, with a print rate of up to 180 lb/printer/day. | |data15 = | ||

|header16 = | |||

|label16 = | |||

|data16 = Product releases of [[D3D Pro 2]] (12" print bed) and [[D3D Pro 3]] (18" print bed), as well as developing the 4x4x8" 3D printer + [[OSE Shredder]] + [[OSE Filament Maker]] to solve the plastic waste issue. OSE's solution is distributed production of construction materials such as plastic lumber and other large objects from waste plastic feedstocks, with a print rate of up to 180 lb/printer/day. | |||

| Line 298: | Line 301: | ||

=Links= | =Links= | ||

* | *[[D3D Genealogy]] | ||

*[[1 Meter Printer]] | |||

*[[Large 3D Printer]] | |||

*[[Open Source High Temperature 3D Printer]] | |||

*[[Microfactory Boot Camp - Scaling to Large 3D Printer with a 1 Meter Bed]] | |||

*[[3D Printer Modules]] | |||

*[[3D Printer Control Panel]] | |||

Latest revision as of 08:20, 27 November 2023

| ||||||||||||||||||||||||||||||||||||||

Enterprise