Laser Cutter: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 27: | Line 27: | ||

==Components== | ==Components== | ||

*[[Laser]] | *[[Laser]] | ||

*[[ | *[[XYZ Table]] | ||

*[[Controller]] | *[[Controller]] | ||

Revision as of 02:54, 20 September 2011

| Laser Cutter | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

A laser cutter enables CNC cutting and engraving of metal, wood, and other materials. Laser cutting works by directing the output of a high-power laser, by computer, at the material to be cut. The material then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Details

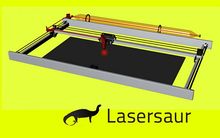

lasersaur from stefanix on Vimeo.

Product Ecology

Uses

- Induction Furnace - Structural Metal

- Multimachine -

- CNC Circuit Mill - Controller

- Motors

- Power

Creates

- 3D Printer - Structural

Components

See Product Ecologies for more information.

Status

The Laser Cutter is currently in the Development phase by Lasersaur, and will be a part of the GVCS when complete.

Research

See Also