CNC Torch Table: Difference between revisions

No edit summary |

|||

| Line 8: | Line 8: | ||

<br/> | <br/> | ||

<html><iframe width="360" height="300" src="https://www.youtube.com/embed//snow7--rvCE?rel=0" frameborder="0" allowfullscreen></iframe></html>]] | <html><iframe width="360" height="300" src="https://www.youtube.com/embed//snow7--rvCE?rel=0" frameborder="0" allowfullscreen></iframe></html>]] | ||

=Summary= | |||

The '''CNC Torch Table''' (aka '''RepTab''') is | The '''CNC Torch Table''' (aka '''RepTab''') is tremendous upgrade for any workshop. This machine enables creation of custom parts for fabrication or replacement of broken components. The CNC Torch Table allows workshops to create replacement parts on the fly for many of the components used in the GVCS. Additionally, the torch table gives workshops the ability to create many of the custom components used in the GVCS Machines. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication. | ||

Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication. | |||

=Status= | =Status= | ||

The 2nd prototype is in progress, more information about the research and development can be found in the [[CNC Torch Table/Research Development|Research & Development]] section. | |||

= | =Additional Non-Torching Tool Functions of the CNC Torch Table= | ||

*As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces. | |||

*A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover. | |||

* | |||

As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces. | |||

A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover. | |||

Additional discussion at [[TorchTableModularTooling]] | Additional discussion at [[TorchTableModularTooling]] | ||

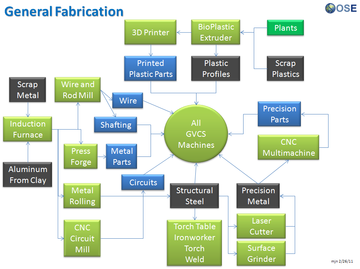

=Product Ecology= | =Product Ecology= | ||

| Line 107: | Line 32: | ||

See [[Product Ecologies]] for more information. | See [[Product Ecologies]] for more information. | ||

=See Also= | =See Also= | ||

Revision as of 16:51, 24 January 2013

Main > Digital Fabrication > RepLab Tools > Torch Table

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Summary

The CNC Torch Table (aka RepTab) is tremendous upgrade for any workshop. This machine enables creation of custom parts for fabrication or replacement of broken components. The CNC Torch Table allows workshops to create replacement parts on the fly for many of the components used in the GVCS. Additionally, the torch table gives workshops the ability to create many of the custom components used in the GVCS Machines. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Status

The 2nd prototype is in progress, more information about the research and development can be found in the Research & Development section.

Additional Non-Torching Tool Functions of the CNC Torch Table

- As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces.

- A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover.

Additional discussion at TorchTableModularTooling

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings Ironworker

Ironworker

Creates

See Product Ecologies for more information.

See Also