CEB Press: Difference between revisions

(→Status) |

No edit summary |

||

| Line 1: | Line 1: | ||

{{ | {{GVCS Header}} | ||

[[File:Machine.jpg|right|400px|thumb|CEB Press (aka "The Liberator")]] | [[File:Machine.jpg|right|400px|thumb|CEB Press (aka "The Liberator")]] | ||

==Overview== | ==Overview== | ||

Revision as of 20:34, 5 September 2011

| CEB Press | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

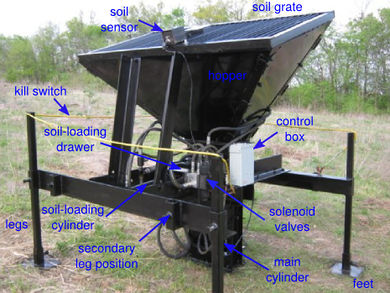

The "Liberator" Compressed Earth Block Press is a machine that makes compressed earth blocks (CEBs).

Detailed Description

The CEB Press takes earth/dirt/soil and squeezes it really hard to make solid blocks which can be used for building. Compressed earth blocks have many advantages as a building material: by making the building materials from the ground on the site, they eliminate the need to cart them in from elsewhere. This cuts down the costs and environmental impact of transport. Compressed earth blocks are very strong and insulate well against both heat and sound. This makes for a very energy-efficient building. Best of all, there is no charge for using dirt; it is literally a dirt-cheap way of building! See the wiki page on Compressed Earth Blocks and the CEB category for more details on building with CEBs.

The Liberator has been fully designed and tested by the Open Ecology team. You can now follow the instructions to build your own, or contact opensourceecology[at]gmail[dot]com if you want to buy a kit or a finished machine.

Building a machine yourself might seem scary, but every step of the process is fully documented and the OSE community is available on our discussion forums if you need help, advice, or a little hand-holding.

With the Liberator, two people can build a 6 foot high (1.83m) round wall, 20 feet (6.1m) in diameter, 1 foot (30cm) thick, in one 8 hour day - though construction time will vary somewhat depending on other factors: preparation time, what equipment is available (tractor etc.) and the quality of the soil. The bigger the block size, the faster a wall is erected. And obviously, the bigger the block size, the heavier the block. Blocks from The Liberator will average 25 pounds (11.3kg).

The torch table will be used to automate the fabrication of the CEB machine, reducing fabrication time by an estimated 20 hours and thus reducing the cost of the final product.

Components

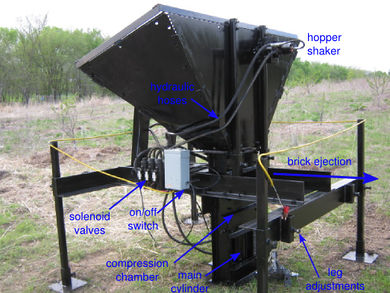

The Liberator consists of -

- A Hopper at the top which you fill with loose dirt. This is made from welded steel. We made the hopper six feet wide, so it can hold a lot of dirt.

- Grate and grate shaker - the grate is at the bottom of the hopper. The grate shaker shakes it so that soil falls through into the compression chamber, while large stones and things like that are caught in the grate.

- A frame that bolts together for easy assembly and disassembly.

- A compression chamber where the bricks are actually pressed. This is a metal box with a nylon liner bolted on the inside. The liner gives the bricks a smoother finish. It will have to be replaced every hundred thousand bricks or so.*Hydraulic cylinders - These are the muscles of the machine; they apply the pressure to the dirt. They are readily removable with pins. There are two hydraulic cylinders:

- The soil drawer - this moves from left to right and performs the dual function of loading soil into the compression chamber and ejecting blocks from the machine

- The main cylinder, which moves up and down and compresses the blocks

- Tractor mount - this is where an external hydraulic power source can be attached to the hydraulic cylinders.

- Pressure gauge

- Controller Box controls the timing and sequence of operations.

Product Ecology

See Product Ecologies for more information.

Uses

- Furnace Steel

- Welder pieces

- Torch Table plates and holes

- Ironworker holes

- PowerCube for power

Creates

- CEB Bricks for Workshop, Greenhouse, HabLab, etc

Solution Statement

The CEB Press provides a solution for using soil as a viable building construction material.

Specifications

| Bricks per minute output | 16 |

|---|---|

| Brick size | 12x6x6 inches (30.5x15.3x10.2 cm) |

| People operating machine | 1-2 |

| Power source | Tractor hydraulics or any hydraulic power source with 6 gallon per minute capacity (22.71 liters per minute) |

| Machine mounting | tractor 3 point hitch or stand-alone foot |

| Hydraulic pressure | 2000psi / 137.90 bar |

| Hydraulic cylinder | 5 inch diameter, 19.6 inch area; 2.5 inch rod |

| Pressing cylinder pressure | 39,250 lb pushing force (~18 tons) |

| Controls | 2 spool, manual, hydraulic valve; automatic version forthcoming. |

| Compressive strength of bricks | 795psi (54.81 bar) using plain earth. 1200psi (82.74 bar) with 10% Portland cement. Strong enough to build a 60-story building [1] |

| Materials: | Structural cold rolled steel construction throughout |

| Height: | 6 foot 11 inches/ 210.82 cm |

| Machine lifetime goals: | 1 million bricks before repairs; liner may be replaced every 100,000 bricks |

| Fabrication time requirement for optimized production: | 3-5 days, about 20 hours of direct fabrication |

| Manual fabrication tooling requirements: | drill press, welder, acetylene torch |

| Optimal fabrication tooling: | XYZ table with torch, MIG welder, hoist |

| Material costs: | $1000-1350 |

Status

Currently the CEB is at product release status and is being actively manufactured at Factor e Farm. The presses will be used heavily as a part of the Factor e Farm Infrastructure Buildout 2011.

See: Brianna Log for production run status updates

The CEB documentation is being actively upgraded to meet Fabrication_Procedure_Standards with the goal of serving as a reference implementation for GVCS documentation.

The first independent replication is in process as of Sep. 2, 2011, by James Slade in Texas.

See Also