CNC Torch Table: Difference between revisions

m (→Cutting Torch) |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Category=Torch Table}} | |||

{{GVCS Header}} | |||

[[Image:CNC Torch Tablepic.jpg|thumb|360px|CNC Torch Table Prototype I, used in [[2011 Production Run]] ]] | [[Image:CNC Torch Tablepic.jpg|thumb|360px|CNC Torch Table Prototype I, used in [[2011 Production Run]] ]] | ||

[[Image:Table_Frame.JPG|thumb|360px|Torch Table Prototype II Design. | [[Image:Table_Frame.JPG|thumb|360px|Torch Table Prototype II Design. | ||

<br/> | <br/> | ||

<html><iframe width="360" height="300" src="https://www.youtube.com/embed//snow7--rvCE?rel=0" frameborder="0" allowfullscreen></iframe></html>]] | <html><iframe width="360" height="300" src="https://www.youtube.com/embed//snow7--rvCE?rel=0" frameborder="0" allowfullscreen></iframe></html>]] | ||

| Line 13: | Line 15: | ||

=Status= | =Status= | ||

==CNC Torch Table Prototype II'''== | ==CNC Torch Table Prototype II'''== | ||

Design is finished. Stepper motor controller is under way. | Design is finished. Stepper motor controller is under way. | ||

*[http://opensourceecology.org/w/images/7/79/CNC_Torch_Table_-_Sketchup_Model.zip Sketchup Model] | *[http://opensourceecology.org/w/images/7/79/CNC_Torch_Table_-_Sketchup_Model.zip Sketchup Model] | ||

Revision as of 07:56, 21 November 2012

Main > Digital Fabrication > RepLab Tools > Torch Table

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

The CNC Torch Table (aka RepTab) is a computer controlled machine that quickly cuts intricate patterns out of large steel sheets, that are difficult to cut by hand. The machine should be able to interpret DXF files and cut out the defined parts.

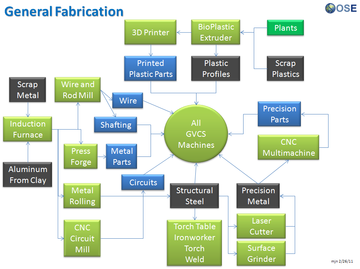

Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Status

CNC Torch Table Prototype II

Design is finished. Stepper motor controller is under way.

- Sketchup Model

- Solidworks model - In progress

- First Run of Prototype II:

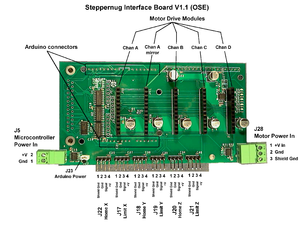

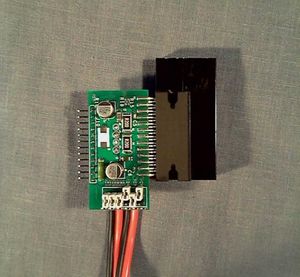

- Results: the mechanical structure is robust and lends itself to torch and CNC wood milling operations. Gantry design by Ben Horton. The innovation here is the Arduino-based stepper motor controller, Steppernug - which can be milled on a CNC circuit mill. This system is a replacement for a proprietary version equivalent to the Gecko G540 in terms of current-handling ability.

- Computer Control Overview

Materials

Get fasteners from Boltdepot

Metric hex nuts, Stainless steel 18-8, 5mm x 0.8mm --- x12 x-axis and y-axis motor mounting (4 per motor)

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 10mm --- x4 z-axis motor mounting

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 16mm --- x12 x and y-axis motor mounting

Cutting Torch

- Oxyacetylene, oxypropane, oxy-biogas. Oxygen: commercial bottled gas or on-site oxygen generator (purchase [1],[2]) (build [3]). Steel only.

- Plasma torch. Cuts aluminum, stainless, others in addition to steel.

CNC Torch Table Prototype I

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings

Creates

See Product Ecologies for more information.