Short description |

| Specifications |

|---|

| Product Ecology |

Uses 3D printed parts printed by itself. |

|---|

| License |

OSHWA and OSI compliant. CC-BY-SA-4.0 International, GPLv3, DIN SPEC 3105. |

|---|

| Module 1 |

Universal Gearless Extruder |

|---|

| Module 2 |

Fast Heated Bed |

|---|

| Module 3 |

Universal Axis CNC motion system |

|---|

| Module 4 |

Universal Controller multipurpose controller |

|---|

| Module 5 |

Universal Frame system |

|---|

| Module 6 |

Heated Bed Chamber system |

|---|

| Key Specification |

Scaled to 2' bed size using the 8 mm Universal Axis. |

|---|

| Construction |

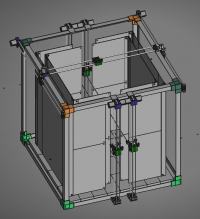

Steel frame with 3D printed corners are used to hang the Universal Axis. Steel-plastic assemblies are used throughout, using 3D printed plastic for complex geometries and steel for strength. |

|---|

| Productivity |

Best-in-class heatbed for speed of heating and temperature (up to 178C). Best-in-class extruder for print speed using rubber (in addition to thermoplastics). Current productivity is 5 lb/24 hr print rate per print head. Features ready scalability to 20 lb/day print rate using the Supervolcano Nozzle. Features scalability to 4-9 print heads for an 80-180 lb/day print rate. |

|---|

| Completion Status |

|---|

|

This fork of the D3D Mega is designed to use multiple 8mm Universal Axes paired together for additional strength on the Z axis, enabling a larger bed size while still using the easy to source and build 8mm axis. |

| Next Steps |

|---|

|

Product releases of D3D Pro 2 (12" print bed) and D3D Pro 3 (18" print bed), as well as developing the 4x4x8" 3D printer + OSE Shredder + OSE Filament Maker to solve the plastic waste issue. OSE's solution is distributed production of construction materials such as plastic lumber and other large objects from waste plastic feedstocks, with a print rate of up to 180 lb/printer/day. |

| Do you want more of this? Get Involved |

| v · d · e |