Well-Drilling Rig

| Well-Drilling Rig | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The Well Drilling Rig enables the construction of water wells. Water is crucial for human and animal consumption, washing, irrigation, and industrial processes. Access to clean drinking water is one of the key challenges facing many countries today. Addressing this need with the GVCS has the potential for far reaching impact.

If this machine plans are changed little to "General Drilling Rig" it can be used also mining purposes, to drill & blast caves, make bolt holes, drill water and geothermal wells etc. There can be two changeable drill heads. One for bigger holes (compressed air driven) and second hydraulic driven (fast) for smaller holes. And modified LifeTrac may carry them. Modified Backhoe offer enough movement for drill head tool.

Description

Well drilling can be broken down into three basic phases:

- breaking up the rock/soil in the well column

- removing the cuttings from the well column

- stabilising the well column and preparing it for production.

Breaking Breaking of rock/soil to produce cuttings is achieved by a cutting tool, either a rotating drill bit or a raised and dropped 'chisel-like' device; for the GVCS well drilling rig we will likely employ the rotating bit design as it is a much more common method of well preparation. The bit is rotated by attaching it to the end of a long series of pipes connected together called the drill string, turning the drill string turns the cutting bit.

Pumping Once the bit has cut up the rock/dirt it needs to be lifted up out of the well. The most common way of doing this is to pump water/mud down the center of the piping that makes up the drill string, and letting it flow out the end of the bit. By continuously pumping more drilling mud into the well, it eventually fills up and the only place left for the mud to go is to be pushed up to the top of the well and spill over the side, carrying the cuttings along with it. This flow of mud and broken up rock spills over the top of the well and is sent to a small settling pond where the rocks and sand settle out of it. After some time in the settling pond the mud is recycled by the mud pump and pushed back down the well again to pick up and remove more cuttings allowing the well to be contiuously drilled deeper and deeper, stopping only to add new sections of drill string.

Stabilizing After the well is drilled to the desired depth it must be finished and put into production. The drill string is withrawn from the well, but the well is left full of water/drilling mud to prevent the sides from caving in until the well is finished. After the drill string is out the casing pipe is slid into the well to prevent caving in of the sides. Once this is done, the drilling mud is removed from the well column leaving it empty. At this point a water bucket or temporary well pump is placed in the well and as much water as possible is drawn up for a test period of 1 to 3 days to clean out any remaining drilling mud and stabilize the aquifer for production. Also during this time the water extraction rate is measured to verify that it is worth continuing to finish the well (poor producing wells may have the casing withdrawn and be re-drilled at a more favorable location). Once the well is shown to be a producing well it is capped with a cement cap, and the water pump is installed making the well operational.

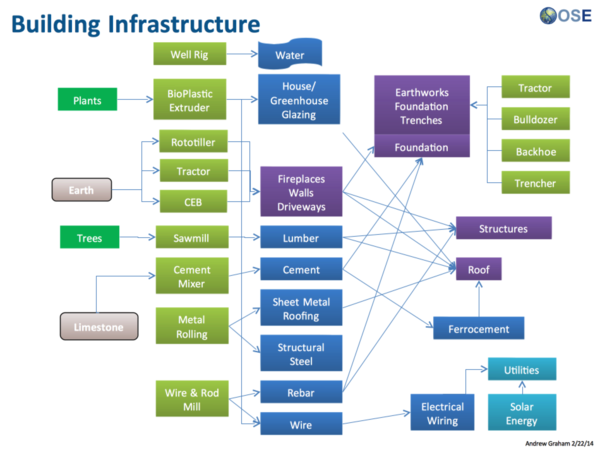

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel CNC Torch Table - Parts

CNC Torch Table - Parts Power Cube - Power

Power Cube - Power Hydraulic Motor - Drill, Ram, Vacuum Pump

Hydraulic Motor - Drill, Ram, Vacuum Pump

Uses

Hydraulic Motor - Pump

Hydraulic Motor - Pump Power Cube - Power

Power Cube - Power Cement Mixer - Cement Cap

Cement Mixer - Cement Cap

Creates

- Water Wells

Components

- Steel

- Drill

- Pipe Casing

- Drill String

- Hoses

- Mud Pump

- Vacuum

Status

The Well Drilling Rig is currently in the research phase of product development

Internal Links

External Links

- GVCS Research

- HydroMissions - Products

- Practica Foundation - Publications

- Drilling Fab

- Life Water - Technical Library

- EMAS - Vimeo: Well Drilling Videos