CNC Torch Table: Difference between revisions

(→Files) |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Image:Backhoe.png|thumb|right|400px|Backhoe]] | |||

=Overview= | |||

The '''CNC Torch Table''' (aka RepTab) is an enabling machine for any workshop. This machine enables creation of custom parts for fabrication or replacement of broken components. | |||

=Versions= | |||

==[[Backhoe 3]]== | |||

Main page for the [[Backhoe 3]]. | |||

Under active development as of Oct 2013 | |||

==[[Backhoe 1]]== | |||

Main page for the [[Backhoe 1]]. | |||

[[Image:Backhoe.jpg|100px|none]] | |||

=Details= | |||

The CNC Torch Table allows workshops to create replacement parts on the fly for many of the components used in the GVCS. Additionally, the Torch Table gives workshops the ability to create many of the custom components used in the GVCS Machines. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication. | |||

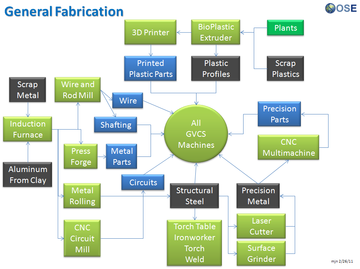

=Product Ecology= | =Product Ecology= | ||

| Line 40: | Line 34: | ||

See [[Product Ecologies]] for more information. | See [[Product Ecologies]] for more information. | ||

=See Also= | =See Also= | ||

| Line 48: | Line 43: | ||

*[[CNC Torch Table/Manufacturing Instructions|Manufacturing Instructions]] | *[[CNC Torch Table/Manufacturing Instructions|Manufacturing Instructions]] | ||

*[[CNC Torch Table/User's Manual|User's Manual]] | *[[CNC Torch Table/User's Manual|User's Manual]] | ||

Move this stuff to version pages: | |||

[[Image:CNC Torch Tablepic.jpg|thumb|360px|CNC Torch Table Prototype I, used in [[2011 Production Run]] ]] | |||

[[Image:Table_Frame.JPG|thumb|360px|Torch Table Prototype II Design. | |||

<br/> | |||

<html><iframe width="360" height="300" src="https://www.youtube.com/embed//snow7--rvCE?rel=0" frameborder="0" allowfullscreen></iframe></html>]] | |||

=Status= | |||

The 2nd prototype is in progress, more information about the [[CNC_Torch_Table_Control_Overview|control system]] and other research and development can be found in the''' [[CNC Torch Table/Research Development|Research & Development]] '''section. In particular, a big piece of development is a robust, open source [[Height Controller]] for oxyacetylene and plasma torches. | |||

The mechanical structure is already built. Prototype 2 build integration is scheduled for June, 2013, as an enabling tool for digital fabrication of the mechanical GVCS tools such as tractors and bulldozers. Steps needed include [[Steppernug]] open source stepper motor driver, Arduino stepper controller, z-height control, trigger, endstops, and CNC toolpath toolchain. Further development involves test-driven design with [[Cool DRV]], [[RAMPS]], DRV-based [[Pololu]]. Building towards universally scalable stepper controller as we begin [[Power Electronics Construction Set]]. | |||

=Files= | |||

Github, mostly solidworks - [https://github.com/Fractal618/CNC-Torch-Table-OSE]. | |||

[http://opensourceecology.org/w/images/d/d1/Creation_Flame_CNC_Torch_Table_Drawings.zip - DXFs of motor mounts]. [http://opensourceecology.org/w/images/7/79/CNC_Torch_Table_-_Sketchup_Model.zip - Sketchup files] | |||

=Additional Notes= | |||

*As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces. | |||

*A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover. | |||

Additional discussion at [[TorchTableModularTooling]] | |||

{{GVCS Footer}} | {{GVCS Footer}} | ||

Revision as of 18:03, 25 October 2013

Overview

The CNC Torch Table (aka RepTab) is an enabling machine for any workshop. This machine enables creation of custom parts for fabrication or replacement of broken components.

Versions

Backhoe 3

Main page for the Backhoe 3.

Under active development as of Oct 2013

Backhoe 1

Main page for the Backhoe 1.

Details

The CNC Torch Table allows workshops to create replacement parts on the fly for many of the components used in the GVCS. Additionally, the Torch Table gives workshops the ability to create many of the custom components used in the GVCS Machines. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Product Ecology

Made with

Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings Ironworker

Ironworker

Creates

See Product Ecologies for more information.

See Also

- CNC Torch Table Crash Course

- Research & Development

- Bill of Materials

- Manufacturing Instructions

- User's Manual

Move this stuff to version pages:

Status

The 2nd prototype is in progress, more information about the control system and other research and development can be found in the Research & Development section. In particular, a big piece of development is a robust, open source Height Controller for oxyacetylene and plasma torches.

The mechanical structure is already built. Prototype 2 build integration is scheduled for June, 2013, as an enabling tool for digital fabrication of the mechanical GVCS tools such as tractors and bulldozers. Steps needed include Steppernug open source stepper motor driver, Arduino stepper controller, z-height control, trigger, endstops, and CNC toolpath toolchain. Further development involves test-driven design with Cool DRV, RAMPS, DRV-based Pololu. Building towards universally scalable stepper controller as we begin Power Electronics Construction Set.

Files

Github, mostly solidworks - [1]. - DXFs of motor mounts. - Sketchup files

Additional Notes

- As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces.

- A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover.

Additional discussion at TorchTableModularTooling