Gasifier Burner: Difference between revisions

Jump to navigation

Jump to search

| Line 4: | Line 4: | ||

==Overview== | ==Overview== | ||

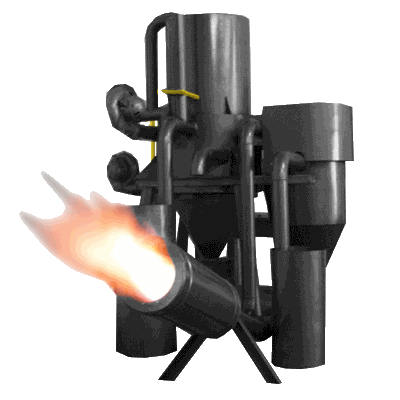

The ''Gasifier Burner'' converts raw biomass into fuel and other useful chemicals. | |||

==Details== | |||

This is achieved by reacting the material at high temperatures (>700°C), without combustion, with a controlled amount of oxygen and/or steam, breaking down the biomass into carbon monoxide, hydrogen, carbon dioxide and methane. The resulting gas mixture is a fuel called [[syngas]]. | |||

==Details== | ==Details== | ||

Revision as of 02:03, 11 September 2011

| Gasifier Burner | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

The Gasifier Burner converts raw biomass into fuel and other useful chemicals.

Details

This is achieved by reacting the material at high temperatures (>700°C), without combustion, with a controlled amount of oxygen and/or steam, breaking down the biomass into carbon monoxide, hydrogen, carbon dioxide and methane. The resulting gas mixture is a fuel called syngas.

Details

Product Ecology

Made with

- Induction Furnace - Steel

Uses

- Baler - burns biomass

- Pelletizer - burns pelletized biomass.

- Steam Generator - uses steam for process.

- Steam Engine - heats the engine

Creates

See Product Ecologies for more information.

Components

- Frame

- Burner

- Mixer

- Pipes

Status

The gasifier burner is currently in the Research phase of development.

See Also

- Biochemicals from Pyrolysis

- Biomass to FuelFischer-Tropsch

- Compressed Fuel Gas

- Pyrolysis Oil

- Biochar

- Babington Burner