Ironworker/Manufacturing Instructions

Jump to navigation

Jump to search

| Ironworker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Introduction

See Ironworkers for introduction.

Build

We start the build of the open source ironworker with a 120 ton hole puncher for poking up to 1.5 inch holes in 1" steel (figure based on Edwards ironworkers) plate.

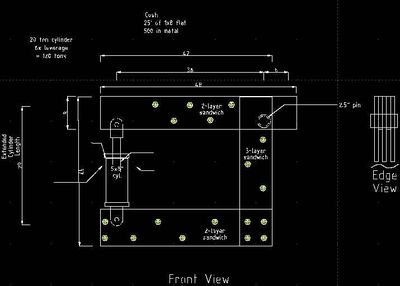

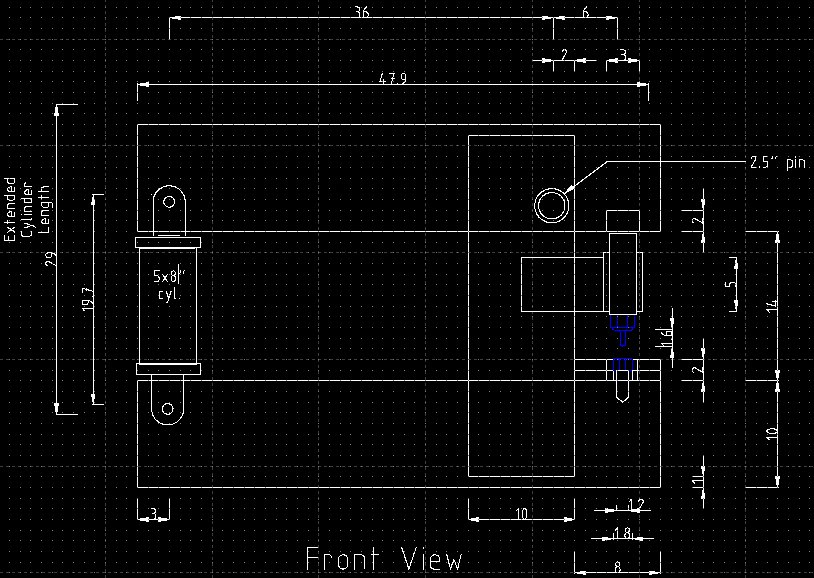

Initial CAD, not finished:

You can download the file here.

Design v0.1

Bill of Materials

- 5"x8" hydrauilic cylinder

- [2]1"x4" pin - for mounting cylinder

- [2]3/4" or 1" washers

- [2] 1"x10"x48" plate - main parallel pieces

- [2] 1"x10"x32" plate - vertical supports

- [2] 1"x2"x3" plate - for reinforcement of pressing surface

- [4] 3/8"x4"x6" angle, 6" long - for legs

- [2] 1"x5"x5" plate - for alignment tube

- [2] 1"x4"x8" plate - for dye holders

- DOM tubing to hold die - 2" long

- Smaller DOM tubing to support die from underneath

- 2.5" DOM tubing, 5" long - for alignment

- 2.5" shaft, 7.7" long - for pressing

- 2.5" DOM tubing, 4" long - for main pin

- 2.5" shaft, 5" long - main pin

Notes: 1"x10" steel costs $233 if steel is 50 cents per pound.