CNC Torch Table

Main > Digital Fabrication > RepLab Tools > Torch Table

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

The CNC Torch Table (aka RepTab) is a computer controlled machine that quickly cuts intricate patterns out of large steel sheets, that are difficult to cut by hand. The machine should be able to interpret DXF files and cut out the defined parts.

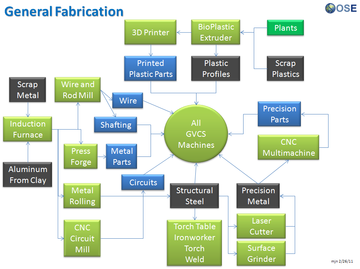

Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Status

CNC Torch Table Prototype II

Design is finished. Stepper motor controller is under way.

- Sketchup Model

- Solidworks model - In progress

- First Run of Prototype II:

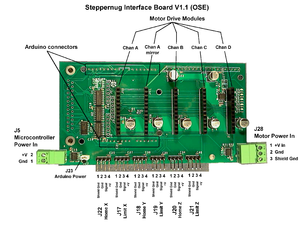

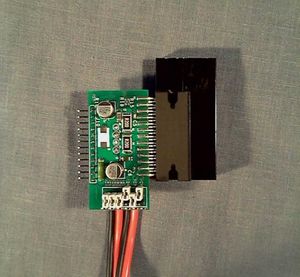

- Results: the mechanical structure is robust and lends itself to torch and CNC wood milling operations. Gantry design by Ben Horton. The innovation here is the Arduino-based stepper motor controller, Steppernug - which can be milled on a CNC circuit mill. This system is a replacement for a proprietary version equivalent to the Gecko G540 in terms of current-handling ability.

- Computer Control Overview

Materials

Get fasteners from Boltdepot

Metric hex nuts, Stainless steel 18-8, 5mm x 0.8mm --- x12 x-axis and y-axis motor mounting (4 per motor)

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 10mm --- x4 z-axis motor mounting

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 16mm --- x12 x and y-axis motor mounting

Cutting Torch

- Oxyacetylene, oxypropane, oxy-biogas. Oxygen: commercial bottled gas or on-site oxygen generator (purchase [1],[2]) (build [3]). Steel only. Best on thick (1 inch +) steel.

- Plasma torch. Cuts aluminum, stainless, others in addition to steel. PP60 Everlast_Plasma_Cutter (alternate Everlast_PowerPro_256)

Marking Function

(From email ChuckH 17:15, 3 December 2012 (CET))

"Plan C": use the CNC table as a marking machine for layout, and do our cuts by hand.

I suggest using round soapstone, like http://www.atlweldingsupply.com/Round-Soapstone-Gross_p_254-1393.html, in some sort of spring-loaded holder. Alternatively, silver sharpies http://www.amazon.com/Sharpie-Metallic-Permanent-Markers-39108PP/dp/B00009RAX4

Although this is clearly not a final solution, it actually has certain advantages:

- Does not require completion of torch height control and plasma supply interface on torch table

- We can mark much faster than we can cut

- Marked parts can be hand-cut in parallel, shortening overall production time

- Glitches in CNC table operation are unlikely to cause ruined parts

(i.e. we can catch them before we cut)

- We can place layout marks for other operations besides cutting

(e.g. center marks for drilling or punching)

- Allows us to prove out most of the torch table toolchain on this build.

Either the soapstone or sharpie will wear down and start making broader, possibly off-center lines. The soapstone can be pointed much like a pencil, while the sharpie you'll just throw out. Probably get a bunch of both and see how they perform.

CNC Torch Table Prototype I

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings

Creates

See Product Ecologies for more information.

Videos

See Also