D3D Universal: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| (271 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

= | =Introduction= | ||

[[ | *A Small [[D3D]] printer designed to be '''ESPECIALLY Easy to Build''' , cheap, and as a tool to build other machines over time | ||

*'''Costs US$200-600 ''' | |||

*Max Build Volume of 6x6x6 inches (150x150x150 mm) | |||

*Great as a First Printer, Clasroom All-in-One Device, or as a print farm componet | |||

*For more high end models see [[D3D]] and [[D3D Pro]] | |||

*[https://www.opensourceecology.org/d3d-universal-2/ We are now producing kits and finished machines] | |||

*Our next build workshops are: https://www.opensourceecology.org/workshops-and-programs/ | |||

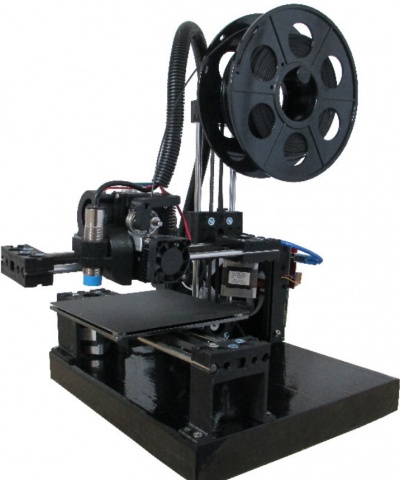

= | =Pictures= | ||

[[File:d3du.jpg|400px]] | |||

'''You can order a kit at https://www.opensourceecology.org/d3d-universal-2/''' | |||

=Development Template= | |||

{{devtemplate|0=D3D Universal|14=80|10=100|2=50|5=95|17=60|19=15|20=80|16=50|15=20|18=80|12=100|3=100|8=80|9=100|13=100|1=95}} | |||

=Enterprise Template= | |||

{| class="wikitable" | |||

|+ Enterprise Template | |||

! | |||

! Description | |||

! Link to Work Product | |||

! % | |||

|- | |||

! scope=row | | |||

| '''PRODUCT''' || || | |||

|- | |||

! scope=row | 1 | |||

| [[Unique Value Proposition]] || [[D3D Universal Unique Value Proposition]] || 0 | |||

|- | |||

! scope=row | 2 | |||

| [[Product Strategy]] || [[D3D Universal Product Strategy]] || 0 | |||

|- | |||

! scope=row | 3 | |||

| [[Cost Structure]] || [[D3D Universal Cost Structure]] || 0 | |||

|- | |||

! scope=row | 4 | |||

| [[Business Plan]] || [[D3D Universal Business Plan]] || 0 | |||

|- | |||

! scope=row | 5 | |||

| [[Open Source Franchise]] || [[D3D Universal Open Source Franchise]] || 0 | |||

|- | |||

! scope=row | | |||

| '''PRODUCTION || || | |||

|- | |||

! scope=row | 6 | |||

| [[Training and Management]] || [[D3D Universal Training and Management]] || 0 | |||

|- | |||

! scope=row | 7 | |||

| [[Facility Design]] || [[D3D Universal Facility Design]] || 0 | |||

|- | |||

! scope=row | 8 | |||

| [[Supply Chain Development]] || [[D3D Universal Supply Chain Development]] || 0 | |||

|- | |||

! scope=row | 9 | |||

| [[Production]] || [[D3D Universal Production]] || 0 | |||

|- | |||

! scope=row | 10 | |||

| [[Quality Control]] || [[D3D Universal Quality Control]] || 0 | |||

|- | |||

! scope=row | | |||

| '''MARKETING || || | |||

|- | |||

! scope=row | 11 | |||

| [[Product Assets]] || [[D3D Universal Product Assets]] || 0 | |||

|- | |||

! scope=row | 12 | |||

| [[Marketing Strategy]] || [[D3D Universal Marketing Strategy]] || 0 | |||

|- | |||

! scope=row | 13 | |||

| [[Marketing Plan]] || [[D3D Universal Marketing Plan]] || 0 | |||

|- | |||

! scope=row | 14 | |||

| [[Product Webpage]] || [[D3D Universal Product Webpage]] || 0 | |||

|- | |||

! scope=row | | |||

| '''SALES AND SUPPORT || || | |||

= | |- | ||

! scope=row | 15 | |||

| [[Sales Strategy|Sales and Distribution Strategy]] || [[D3D Universal Sales Strategy]] || 0 | |||

= | |- | ||

! scope=row | 16 | |||

| [[Customer Support]] || [[D3D Universal Customer Support]] || 0 | |||

= | |- | ||

! scope=row | 17 | |||

| [[Shipping]] || [[D3D Universal Shipping]] || 0 | |||

[ | |- | ||

! scope=row | 18 | |||

| [[Open Source Everything Store]] || [[D3D Universal Open Source Everything Store]] || 0 | |||

|- | |||

! scope=row | | |||

| '''IMPROVEMENT''' || || | |||

|- | |||

! scope=row | 19 | |||

| [[Marketing and Sales Data]] || [[D3D Universal Marketing and Sales Data]] || 0 | |||

= | |- | ||

! scope=row | 20 | |||

| [[Customer Feedback]] || [[D3D Universal Customer Feedback]] || 0 | |||

|- | |||

! scope=row | 21 | |||

| [[Continuing Improvement]] || [[D3D Universal Continuing Improvement]] || 0 | |||

|- | |||

! scope=row | 22 | |||

| [[Future Work]] || [[D3D Universal Enterprise Future Work]] || 0 | |||

|} | |||

=Design Concepts= | |||

= | ==Plotter== | ||

[[ | *[[Pen Holder Toolhead]] | ||

*[[PCB Plotter]] | |||

embedded my website on wiki [https://feadi.github.io/OSE/ https://feadi.github.io/OSE/]. | |||

Played with gtlf-viewer | |||

<html><iframe src="https://gltf-viewer.donmccurdy.com#kiosk=1&model=https://feadi.github.io/OSE/gltf/gltf/test01.glb" style="width: 800px;" height="600px" frameBorder="0"></iframe></html> | |||

< | =Wiring= | ||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10217401078076065&width=500" width="500" height="379" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | |||

=Troubleshooting= | |||

*'''[[D3D Universal Troubleshooting Guide]]''' - add videos | |||

Clog troubleshooting 1st step in checklist [https://youtu.be/09VkDHkd7NA] | |||

=FAQ= | |||

*[[D3D Universal FAQ]] | |||

=D3D Universal First Print Checklist= | |||

Assume we have power and correct motion - how do you assure the printer extruder is working properly? This is specific to extruder - outside of any other controller and system integration issues: | |||

#Check temperature of nozzle - look at LCD screen. Make sure 230C | |||

#If at temperature, load filament. Did it go in right away. If not take out filament - look down the hole and check alignment. Make sure the filament drive gear - perfectly aligns above heat break hole. | |||

#If 3 mm filament - make sure that it doesn't widen out at the cut and that it's 2.85 mm, not 3.0 mm | |||

#Easy flow if you push it in by hand. | |||

#Check the babystepping. For smooth flat first layer. | |||

#Make sure physical obstruction does not exist for print bed going above end 3D printed pieces on bed. | |||

#Make sure you have thermal paste beteen heat sink and fan heat sink | |||

#Make sure you have theraml past - on the heat break into the heat sink | |||

#Make sure the fan is spinning. | |||

#Make sure the set screw is hight on extruder drive gear. | |||

#Make sure the line on end of extruder shaft is spinning. | |||

#Check that filament is feeding through by marking with a white sharpie. Or feel by hand. | |||

#Make sure tension on spring is tight - put shims in the pocket if not. | |||

#Make sure the extruder tension screw is tight | |||

#Make sure that when you hold filament, it pulls hard - you can't stop it readily. | |||

#Make sure nozzle is below the plastic printed parts | |||

#Make sure height probe is ABOVE nozzle | |||

#Cut off the tip of heat sock. | |||

#Let printer extruder cool down before turning the fan off | |||

==Software First Print Checklist== | |||

#Make sure you have 1.75 or 2.85 on the filamnet size | |||

#Make sure you have Marlin Universal here | |||

#Make sure you have Marlin Universal .ini file. | |||

#Check that measurements of parts are correct in FreeCAD. | |||

=Working Doc= | |||

==Includes Review and Data Collection== | |||

<html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vQOvWBdHZ8cYcGu1_brqbhbd7GpU_vYZjiu72ffANSg8Wl2LrdN7v8BjJixLS4FP_KVxLgdXlmpDh-o/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="389" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | |||

[https://docs.google.com/presentation/d/1W5hmlqCsap-q-SiPrjyBIqXnOrp_A4rFG1lPcPm5jfo/edit edit] | |||

= | =See Also= | ||

*[[3D Printer Genealogy]] | |||

*'''[[D3D Universal Build Manual]]''' | |||

*'''[[D3D Universal Production Manual]]''' | |||

*[[D3D Universal Log]] | |||

*[[D3D Pro]] | |||

*[[D3D Simple]] - build from 2019 | *[[D3D Simple]] - build from 2019 | ||

*[[December 2019 Production Run]] | |||

*[[D3D Simple Kit Preparation]] | |||

*[[D3D Simple Wire Bundle Attachement]] | |||

Latest revision as of 00:35, 13 March 2021

Introduction

- A Small D3D printer designed to be ESPECIALLY Easy to Build , cheap, and as a tool to build other machines over time

- Costs US$200-600

- Max Build Volume of 6x6x6 inches (150x150x150 mm)

- Great as a First Printer, Clasroom All-in-One Device, or as a print farm componet

- For more high end models see D3D and D3D Pro

- We are now producing kits and finished machines

- Our next build workshops are: https://www.opensourceecology.org/workshops-and-programs/

Pictures

You can order a kit at https://www.opensourceecology.org/d3d-universal-2/

Development Template

Enterprise Template

Design Concepts

Plotter

embedded my website on wiki https://feadi.github.io/OSE/.

Played with gtlf-viewer

Wiring

Troubleshooting

- D3D Universal Troubleshooting Guide - add videos

Clog troubleshooting 1st step in checklist [1]

FAQ

D3D Universal First Print Checklist

Assume we have power and correct motion - how do you assure the printer extruder is working properly? This is specific to extruder - outside of any other controller and system integration issues:

- Check temperature of nozzle - look at LCD screen. Make sure 230C

- If at temperature, load filament. Did it go in right away. If not take out filament - look down the hole and check alignment. Make sure the filament drive gear - perfectly aligns above heat break hole.

- If 3 mm filament - make sure that it doesn't widen out at the cut and that it's 2.85 mm, not 3.0 mm

- Easy flow if you push it in by hand.

- Check the babystepping. For smooth flat first layer.

- Make sure physical obstruction does not exist for print bed going above end 3D printed pieces on bed.

- Make sure you have thermal paste beteen heat sink and fan heat sink

- Make sure you have theraml past - on the heat break into the heat sink

- Make sure the fan is spinning.

- Make sure the set screw is hight on extruder drive gear.

- Make sure the line on end of extruder shaft is spinning.

- Check that filament is feeding through by marking with a white sharpie. Or feel by hand.

- Make sure tension on spring is tight - put shims in the pocket if not.

- Make sure the extruder tension screw is tight

- Make sure that when you hold filament, it pulls hard - you can't stop it readily.

- Make sure nozzle is below the plastic printed parts

- Make sure height probe is ABOVE nozzle

- Cut off the tip of heat sock.

- Let printer extruder cool down before turning the fan off

Software First Print Checklist

- Make sure you have 1.75 or 2.85 on the filamnet size

- Make sure you have Marlin Universal here

- Make sure you have Marlin Universal .ini file.

- Check that measurements of parts are correct in FreeCAD.

Working Doc

Includes Review and Data Collection