CNC Torch Table

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Main > Digital Fabrication > RepLab Tools > Torch Table

Overview

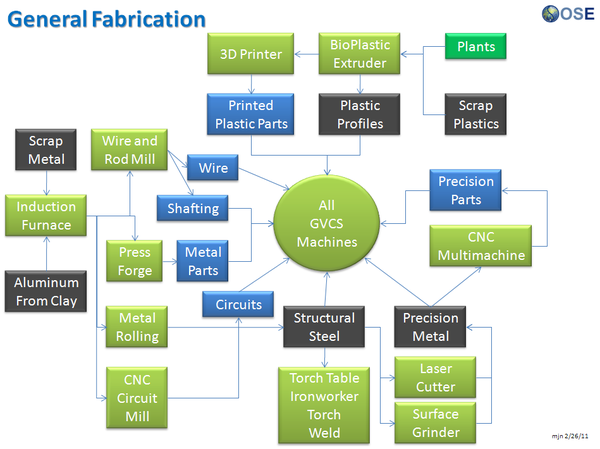

The CNC Torch Table is a table capable of cutting 2D shapes out of steel. It is a valuable tool for replication because of this capability. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table.

The CNC Torch Table provides a quicker solution for cutting sheet metal, especially into intricate patterns that are difficult to cut by hand.

The 2nd prototype is currently being designed and prototyping will take place in June 2012.Chris DeAngelis 03:40, 8 June 2012 (CEST)

Description

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings

Creates

See Product Ecologies for more information.

Design

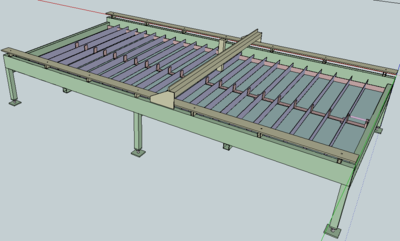

Sketchup file In progress. Chris DeAngelis 03:40, 8 June 2012 (CEST)

Components

Specifications

Status

Prototype I Currently being used in experimental production runs. Tighter integration of Digital Fabrication is being researched as is the software toolchain (which is a current bottleneck).

Prototype II

- First step: perfection of mechanical design for replicability to 1/32" over 4x8' area

- Need open source controller, end stops, and z height automation/detection.

- We could use existing structure, with modifications. Right now we use gear rack. We can simplify the carriage structure.

- If we want to go all out - we could use full gas flow control - but that is probably beyond the scope of the present program - as it would require expensive parts until we can manufacture them ourselves.

- Open source stepper motors would be a good addition - if we could find somebody to design/fab them - that would be great.

- Computer vision for fully automated cutting would be the last step.

- Next steps: stiffening frame design to accommodate router heads

- Interview with owner of Ben's excellent DIY table setup in Smithville, TX:

Suggested steps from Luke Iseman

video of ben's setup:http://opensourceecology.org/wiki/CNC_Torch_Table photos of OSE's current table, including measurements: http://opensourceecology.org/wiki/Torch_Table_Build DIY standalone sensor ideas: http://opensourceecology.org/wiki/Sensing_Distance_from_Work_Piece . note particularly the circuit i found for an independent z-axis control CNC circuit mills: http://opensourceecology.org/wiki/CNC_Circuit_Mill . comparison of existing kits, and updated parts list on mantis 9 ( http://opensourceecology.org/wiki/Mantis_9 )

recommended next steps: 1. get the candcnc.com 's dragon-cut 620-4 and implement on the current table. utilize your same bearing setup for the z-axis. 2. build the mantis 9 , but use the snaplock electronics.

Photos

See Also

- Torch Table Build Prototype 1 Completion

- Torch Table Specifications

- Open_Source_Torch_Table_Prototype_II