CNC Torch Table: Difference between revisions

No edit summary |

(→Status) |

||

| Line 22: | Line 22: | ||

Prototyping scheduled for June 2012<br/> | Prototyping scheduled for June 2012<br/> | ||

[[User:Chris DeAngelis|Chris DeAngelis]] 04:08, 8 June 2012 (CEST) | [[User:Chris DeAngelis|Chris DeAngelis]] 04:08, 8 June 2012 (CEST) | ||

[SolidWorks File https://dl.dropbox.com/u/20960013/OSE/Torch%20Table%20no%20Fillets.zip] | |||

==Sourcing== | ==Sourcing== | ||

Revision as of 16:54, 27 June 2012

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Main > Digital Fabrication > RepLab Tools > Torch Table

Overview

The CNC Torch Table is a table capable of cutting 2D shapes out of steel. It is a valuable tool for replication because of this capability. Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table.

The CNC Torch Table provides a quicker solution for cutting sheet metal, especially into intricate patterns that are difficult to cut by hand.

The 2nd prototype is currently being designed and prototyping will take place in June 2012.Chris DeAngelis 03:41, 8 June 2012 (CEST)

Status

CNC Torch Table I

Prototyped and Tested in experimental production runs.

Identified software toolchain as a performance bottleneck.

CNC Torch Table II

Table frame design in progress:

SketchupFile

Prototyping scheduled for June 2012

Chris DeAngelis 04:08, 8 June 2012 (CEST)

[SolidWorks File https://dl.dropbox.com/u/20960013/OSE/Torch%20Table%20no%20Fillets.zip]

Sourcing

Parts

Sourcing Parts!

Components

Plan of Action

- Design ergonomic frame and motracks and gantry on it

- Stiffen frame design to accommodate router heads

- Perfect mechanical design for replicability to 1/32" over 6x12' area

- Research full gas flow control - this may be beyond the scope of the present program - as it would require expensive parts until we can manufacture them ourselves.

Videos

Product Ecology

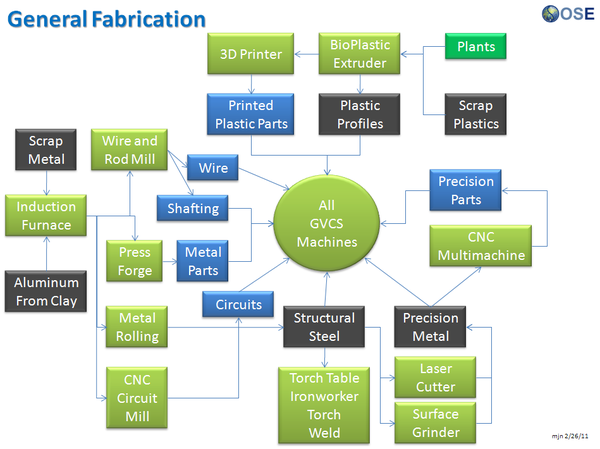

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings

Creates

See Product Ecologies for more information.

Design

Sketchup file In progress.

Chris DeAngelis 19:48, 14 June 2012 (CEST)

Design Rational

- Clearance to cut 4" square tube 20 feet long.

- Clearance to cut 6" square tube 10 feet long. (without removal of "ribs")

- Clearance to cut 10" square tube 10 feet long. (with removal of "ribs")

- Reasonable rigidity is prefered for the frame design. The level of rigidity should be decided on a quantitative basis, however for the scope of this prototype rigidity should always be considered on a qualitative basis at least.

Photos of other Torch Tables

See Also

- Torch Table Build Prototype 1 Completion

- Plasma Cutter trigger wiring - Plasma_Cutter_Design

- Torch Table Specifications

- Open_Source_Torch_Table_Prototype_II