CNC Torch Table

Main > Digital Fabrication > RepLab Tools > Torch Table

| CNC Torch Table | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

The CNC Torch Table (aka RepTab) is a computer controlled machine that quickly cuts intricate patterns out of large steel sheets, that are difficult to cut by hand. The machine should be able to interpret DXF files and cut out the defined parts.

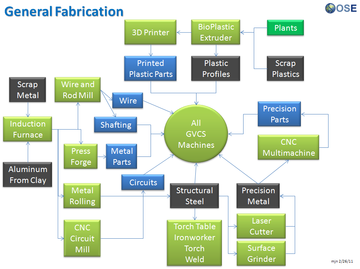

Many parts that make up the 50 GVCS Tools can be cut on the CNC Torch Table, making this machine valuable for replication.

Mechanical

CNC Table Base Frame (including legs and holding flats)

Fasteners from BoltDepot

Metric hex nuts, Stainless steel 18-8, 5mm x 0.8mm --- x12

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 10mm --- x4 z-axis motor mounting

Metric socket cap, Stainless steel 18-8, 5mm x 0.8mm x 16mm --- x12 x and y-axis motor mounting

Electronics

- Cnctorchtable.svg

CNC 3-Stepper Electronics

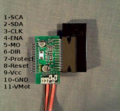

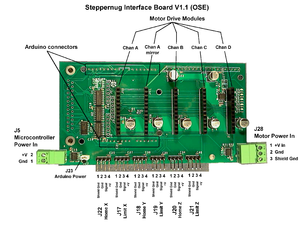

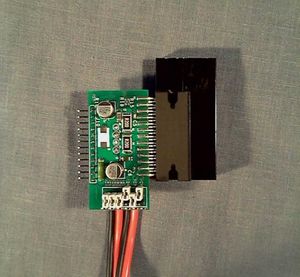

The CNC Torch Table uses the heavy duty Electronics Case with the reliable Arduino Uno microcontroller that controls open-source stepper drivers called Steppernugs

External wiring is easy with the use of Terminal Blocks

Fans can be powered with the voltage regulator.

End Effector

This is the plasma cutter that the CNC Torch Table will be designed to work with. In the event that this cutter is no longer available here are the important specifications: Adjustable Post Flow (power plasma only) control up to 60 seconds to improve consumable and torch life. Front air pressure adjustment makes adjusting pressure easy and painless. (PowerPlasma only) Front air pressure gauge allows quick verification of air pressure. Over Current and Air Pressure light indicators keep you updated on your units operating condition. Suitable for use with 11,000 W "clean power" generators 60AMP 120/220Volt 50/60HZ Plasma Cutter. Cuts 3/8-Inch to 1-1/4-Inch

Status

CNC Torch Table Prototype II

Design is finished. Stepper motor controller is under way.

- Sketchup Model

- Solidworks model - In progress

- First Run of Prototype II:

- Results: the mechanical structure is robust and lends itself to torch and CNC wood milling operations. Gantry design by Ben Horton. The innovation here is the Arduino-based stepper motor controller, Steppernug - which can be milled on a CNC circuit mill. This system is a replacement for a proprietary version equivalent to the Gecko G540 in terms of current-handling ability.

- Computer Control Overview

Cutting Torch

- Oxyacetylene, oxypropane, oxy-biogas. Oxygen: commercial bottled gas or on-site oxygen generator (purchase [1],[2]) (build [3]). Steel only. Best on thick (1 inch +) steel.

- Plasma torch. Cuts aluminum, stainless, others in addition to steel. PP60 Everlast_Plasma_Cutter (alternate Everlast_PowerPro_256). Plasma gas: air or oxygen

Additional (non-Torch) Tool Functions

As a large x-y-z coordinate table, the Torch Table has potential applications with other tooling besides a cutting torch. One limitation is that the drive system is not powerful enough or stiff enough to support heavy cutting-tool forces.

A modular tool mounting (possibly dual mounting, so two tools could be available simultanously) would facilitate tool changeover.

Additional discussion at TorchTableModularTooling

CNC Torch Table Prototype I

Product Ecology

Made with

Induction Furnace - Steel

Induction Furnace - Steel Multimachine - Precision Guides, bearings

Multimachine - Precision Guides, bearings Ironworker

Ironworker

Creates

See Product Ecologies for more information.

Videos

See Also