Nickel-Iron Battery

| Nickel-Iron Battery | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

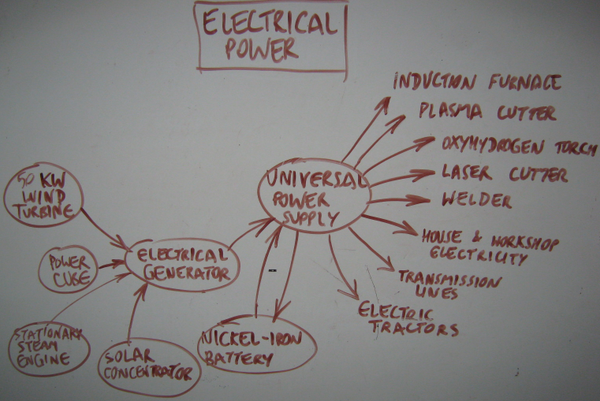

The Nickel Iron Battery is the primary electrical energy storage device for the GVCS.

Advantages:

- Long lifetime of 50 years

- Open source design of electrodes

- Cells scalable: from 1 to 50kW hrs

- Nickel and iron obtained from scrap stream, reprocessed via Induction Furnace

- Completely closed loop material cycle ecology

https://www.youtube.com/watch?v=K84PywMwjZg

Detailed Description

The nickel-iron battery (NiFe battery) or "edison cell" is a storage battery having a nickel oxide-hydroxide cathode and an iron anode, with an electrolyte of potassium hydroxide (lye can be used as a substitute).

The active materials are held in nickel-plated steel tubes or perforated pockets.

It is a very robust battery which is tolerant of abuse, (overcharge, overdischarge, and short-circuiting) and can have very long life even if so treated.

It is often used in backup situations where it can be continuously charged and can last for more than 20 years.

Nickel-iron batteries have ~50 year lifetimes, compared to a few-year lifetime of lead acid batteries. They are environmentally more benign, and lend themselves to local recycling and fabrication. They can have higher discharge rates and faster charge times than lead-acid batteries depending on mechanical design of the electrodes etc, so they lend themselves not only to off-grid power, but also to power electronics applications such as welding and heavy workshop power. In China a company by the name of changhong batteries makes a version of them for use in automotive starter batteries. Their energy density is half that of lead-acid batteries, but their long lifetime and deep discharge ability makes them highly relevant to the GVCS, including to electric farming equipment as the next generation of LifeTrac infrastructure.

The Edison Battery was developed and promoted primarily by Thomas A Edison.

Product Ecology

| From | Uses | Creates | Enables |

|---|---|---|---|

Components |

|

Components

Anode Compound

- iron plate - low carbon, mild steel (demo)

- iron graphite compounded (Edison)

- iron oxide

node Construction

- plain plate (demo)

- pocket plate with mesh inserts (Edison)

Cathode Compounds

- nickel hydrate and pure nickel flake (Edison)

http://en.wikipedia.org/wiki/Nickel%28II%29_hydroxide

Nickel(II) carbonate can be combined with water to form Nickel(II) oxide, which can be used in cells. It generates Carbon Dioxide when mixed with water, which may affect Potassium Hydroxide in solution. Mix with water and allow to complete outgassing and dry before building the cell.

Nickel(III) hydroxide "Nickel Oxide Black" and Nickel(II) carbonate "Green" are used as clay/ceramic colorants and available cheaply from ceramic and pottery related websites ... and though the purity is considered lower, it is still usuable for experimentation at a much lower cost.

Cathode Construction

- plain plate (demo)

- pocket plate with mesh inserts (Edison)

- generally nickel-plated rather than pure nickel

- Nickel sponge

- Sintered nickel powder

- Nickel mesh/cloth

Electrolyte

- aqueous potassium hydroxide

- link

- Water (121g per 100ml)

- sodium hydroxide (alternate, lower voltage)

- lithium (modern additive)

Cell Casing

- nickel-plated steel box, rubber seals (Edison)

- plastic box (modern commercial)

- glass jars (demo projects)

- pvc cylinders (Ed's Workshop)

Status

The Nickel-Iron Battery is currently in the research phase of development.

See Also

Other Communities

http://offgrid2.altervista.org/viewforum.php?f=7