3D Printer

3D Printer Research and Development

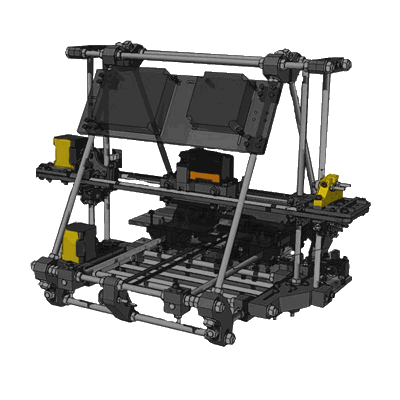

The OSE printer is called D3D - for Distributive Enterprise 3D Printer. For Current Work see 3D Printer Genealogy.

Overview

3D Printers are a subset of CNC machines: they use stepper motors to move along X, Y, and Z axes according to gCode - essentially a text file with thousands of lines of coordinates and special commands (such as "return to origin" or "set nozzle temperature"). As motors on each axis moves the nozzle through 3D space, an additional motor feeds plastic filament through a heating element, very much like an automatic hot glue gun.

The software that turns a 3D model (such as an .stl or .obj) into instructions telling the printer how to move is called a "slicer" - it slices a model into layers that will stack up to make the finished object.

Many options exist for controlling the printer with your computer - nowadays several "slicers" can also connect to the printer directly, streamlining the printing process.. As a central backbone of Digital Fabrication, the end goal of 3D printers is to be able to print anything.

Genealogy

See full genealogy at 3D Printer Genealogy

Details

Types of 3D Printers

Printing Process

(just adding a note here, please move where it fit better) To improve movement speed/accuracy of the printer head i was thought about a dual motor set (each axis) coupled with a differential gear-set so would be possible to reduce or multiply output turns with a digital controller that regulate the ratio of the two motors rotation. (not sure how to implement this and not sure it may be so effective, i just believe this may open for bigger volume printers (3m cube hypothesis). (adexmont 18/nov/2018)

Applications

http://www.instructables.com/id/3D-Printing-3D-Print-A-Solderless-Circuit-Board/

https://www.reddit.com/r/functionalprint

http://readwrite.com/2014/01/31/why-you-want-a-3d-printer-in-your-home

http://www.thingiverse.com/thing:113865

http://www.thingiverse.com/explore/newest/tools

http://www.treehugger.com/lawn-garden/garden-3d-10-things-you-can-3d-print-your-garden.html

http://3dprint.com/34873/3d-printed-lawn-mower/

https://www.pinterest.com/pin/412712753326603895/

https://www.pinterest.com/pin/412712753326427241/

https://i.materialise.com/blog/redesigning-the-bike-frame-james-novaks-experiment-with-3d-printing

http://design-milk.com/keystones-studio-minale-maeda/

http://www.instructables.com/id/Open-Source-3D-Printed-Water-Filter/

https://www.pinterest.com/pin/412712753325305467/

https://all3dp.com/3d-printed-laptop-case/

Product Ecology

| From | Uses | Creates | Enables |

|---|---|---|---|

|

Components

|

|

Status

See past work related to Factor e Farm at RepRap Build.

Currently 3D printer designs are being researched, with the goal of full integration into the Product Ecology of GVCS technologies.

3D printer technology is currently undergoing a flourishing of innovation. As a relatively new technology (2003), many experimental designs and techniques are being explored by thousands of groups worldwide.

See D3D_Landing_Page for the most recent work on this machine

See Also

- Comparison of 3D Printers

- RepRap Build

- Equipment/Lulzbot_a0_101

- Equipment/Taz

- RepLab

- 3D Ceramic

- Stepper Motor

- MIT Machines that Make

- Electron Beam Melting

- Sintering

- Ball Mill

- RepRap MetalicaRap subproject, investigating inexpensive, self-replicating electron beam melting machine design for 3D metal object and solar cell printing

- Cermets, materials that may be suitable for 3D ceramic printing techniques but give material properties superior to those of either metals or ceramics

Further reading

http://www.gifted.uconn.edu/confratute/pdf/HR2015/3D_Printing-Luria-Hack.pdf