Global Village Construction Set

Introduction

The Global Village Construction Set is a set of 50 industrial machines that allow for the creation of a small-scale civilization with modern comforts.

See also the Crash Course and GVCS Rollout Plan

Guiding Ideas

- Open Source - we freely publish our 3d designs, schematics, instructional videos, budgets, and product manuals on our open source wiki and we harness open collaboration with technical contributors.

- Low-Cost - The cost of making or buying our machines are, on average, 8x cheaper than buying from an Industrial Manufacturer, including an average labor cost of $15 hour for a GVCS fabricator.

- Modular - Motors, parts, assemblies, and power units can interchange, where units can be grouped together to diversify the functionality that is achievable from a small set of units.

- User-Serviceable - Design-for-disassembly allows the user to take apart, maintain, and fix tools readily without the need to rely on expensive repairmen.

- DIY - (do-it-yourself) The user gains control of designing, producing, and modifying the GVCS tool set.

- Closed Loop Manufacturing - Metal is an essential component of advanced civilization, and our platform allows for recycling metal into virgin feedstock for producing further GVCS technologies - thereby allowing for cradle-to-cradle manufacturing cycles

- High Performance - Performance standards must match or exceed those of industrial counterparts for the GVCS to be viable.

- Flexible Fabrication - It has been demonstrated that the flexible use of generalized machinery in appropriate-scale production is a viable alternative to centralized production.

- Distributive Economics - We encourage the replication of enterprises that derive from the GVCS platform as a route to truly free enterprise - along the ideals of Jeffersonian democracy.

- Industrial Efficiency - In order to provide a viable choice for a resilient lifestyle, the GVCS platform matches or exceeds productivity standards of industrial counterparts.

The Tools

Enterprise Community Contract

Enabling Technology - Salient Features of Technology Base

Without going into details, the main features for the comprehensive technology base are:

- Hybridization of power devices - decoupling of power source from the working unit in order to produce electrical drive is a formula for increasing integrated efficiency of electromechanical devices such as electric vehicles, tools, heavy equipment, etc. For example, the hybrid car decouples the engine from its wheels by using an electrical generator to feed electric wheel motors. Note that this eliminates the clutch, transmission, crank case and its oil, differential, drive train, and other parts, and replaces these items with electric wire from the generator to electric motor. This is a huge efficiency leap, one in fuel efficiency, and two, in eliminating billions of dollars of industry which is outdated today due to the hybridization option. As such, we can talk of complex machines with huge simplification, assuming easy access to infinitely scaleable and controllable, low cost electric motors (these do not exist today). For example, we can envision an agricultural combine where each moving part is powered by its own electric motor - producing a leap in simplification and maintenance of the overall machine - as all belts, pulleys, gears, and other power transmission components driven by a single engine - are all replaced by electric wire. One can point to many examples where such strategy would provide leapfrog advance in device simplicity and maintenance.

- Solar turbine power generation including heat storage - look at Solar Turbine CHP System

- Open source fab lab - combine and expand the [1] with xyz table as in RepRap (http://reprap.org/), and you can envision a robust fabrication device that integrates open source computer aided design (CAD) and computer aided manufacturing (CAM). This device would perform a large variety of machining and fabrication operations, and would be producible at the cost of materials if metal casting is available. When deployed, we are talking of producing any advanced object or device at the cost of materials. Would you like to fabricate an electric motor for your personal transport vehicle? Here, I'll email you a file to make on your local village fabber. In practice, one could conceptualize a single or several Multimachines, with their milling-drilling-lathing functions, surrounding an xyz motion platform with interchangeable heads. These heads could include acetylene torch attachment, plasma cutter, CO2 laser, router, hot wire, or additive heads such as a plastic extruder found in RepRap. This overall fab lab concept could start with a basic machine such as the Multimachine, with computer controls and table added in time. As such, this is a realistic proposition - with supporting open source knowhow with significant advancement already available. This propels civilization to new levels of decentralized material prosperity, and implies significant reduction of resource conflicts, especially if material feedstocks are sourced locally - as in the next point.

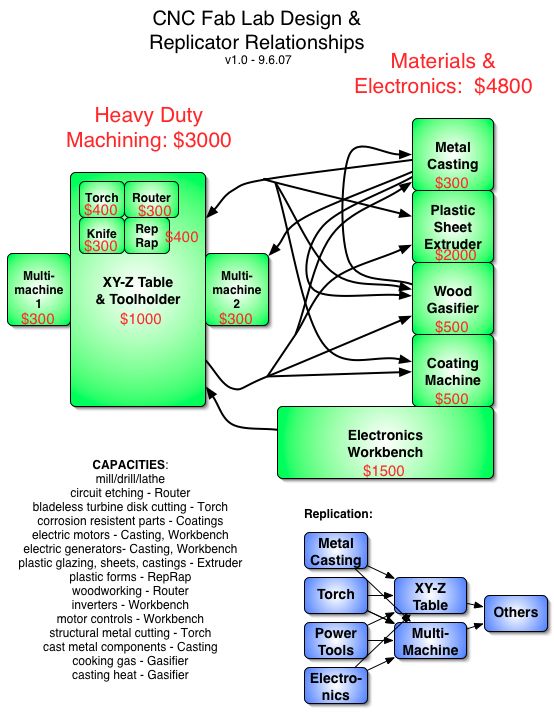

Here is an initial Fab Lab design:

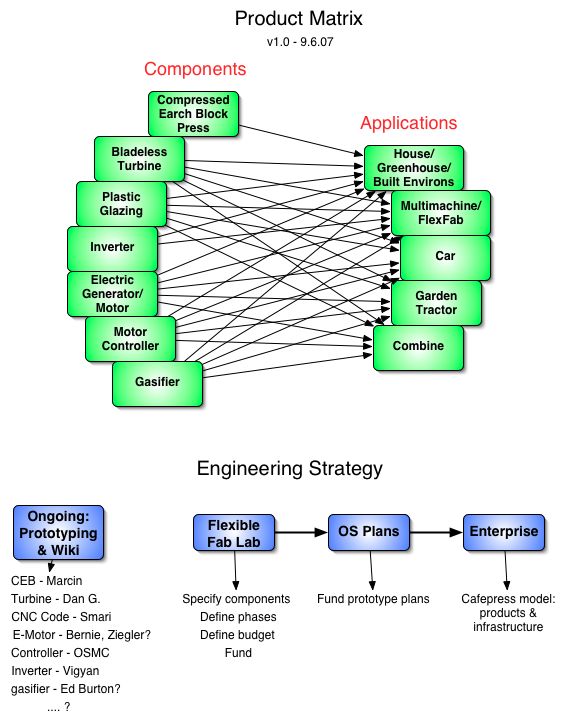

Here is a sample Product Matrix that falls right out of Fab Lab capacities:

- Production of local feedstocks-

- Wood and structural masonry compressed earth block (CEB) for construction - produced from on-site trees and soils

- Compressed Fuel Gas for cooking or melting metal - gas produced from trees

- Bioplastics - such as cellophane from trees

- Biofuels - Fuel Alcohol in temperate zones, palm oil in tropical zones

- Industrial detritus (waste materials) processing - includes Metal Casting and Extrusion or Plastic Extrusion & Molding

- Aluminum Extraction From Clays

Sample Scenario

Imagine a village with buildings of dirt (CEB) with year-round greenhouses (sawmill, CEB, bioplastics from local trees), with all facility energy produced by a solar turbine, where people drive hybrid cars with car bodies (bioplastics) made from local weeds, with critical motors and metal structures (aluminum) extracted from on-site clay, which are fueled by alcohol produced on-site, on a wireless network linked to the greater world. That's just a sampling of the technology base. Food, energy, housing sufficiency. There are no poor among us - because we are all evolving human beings and farmer scientists.

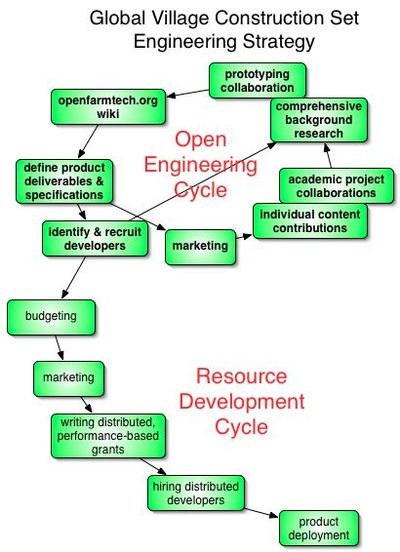

Development process

OSE Spec

Working Assumptions

See Also

- Product Ecologies - Illustrates how the different components of the GVCS relate with one another

- Tool Descriptions - Describes each of the GVCS Tools

- Crash Course

- GVCS Rollout Plan

Media

- TED Talk

- Archived Presentations

- GVCS Thumbs - for media remixing.

| OSE Required Reading | |||

|---|---|---|---|

| Wiki instructions · Crash course on OSE · Global Village Construction Set · Getting Started Guide · Team Culturing · Version control - Genealogies | |||