Induction Furnace/Research Development: Difference between revisions

(Initial rough estimate of production) |

|||

| Line 21: | Line 21: | ||

The furnace also needs a water cooling system, especially for steel melting. | The furnace also needs a water cooling system, especially for steel melting. | ||

The method of electromagnetic induction is similar to the function of transformers, and in fact a transformer is one component of an induction furnace, used for tuning tank circuit to frequency in the case of fixed frequency power source. | The method of electromagnetic induction is similar to the function of transformers, and in fact a transformer is one component of an induction furnace, used for tuning tank circuit to frequency in the case of fixed frequency power source. | ||

The induction furnance should be designed to be capable of melting all the steel required to cast base metal parts for the GVCS. | |||

Therefore, the selection or engineering of the power supply and water cooling system should have a backtracked dependency from all the CAD parts such that the 'time to melt' the GVCS parts is reasonable. Perhaps a month of operation is a good intitial target? | |||

This might be a significant volume of metal... Such as several metric tons. The best rough estimate I can give is 50 * 100 = 5000kg of metal (an average of 100kg per machine) and a budget of 30 days with continous 24/7 operation, that's 10000/30/24 = ~7kg to melt per hour. | |||

Before better CAD models are available, it might make sense for an intelligent being to estimate the machines and render a histogram of the estimated machine metal weights. | |||

==Design== | ==Design== | ||

Latest revision as of 17:57, 17 November 2025

| Induction Furnace | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Overview

Research in creating the Induction Furnace with the goal of creating a design that fully complies with OSE Spec.

Research

A good place to start is to understand what's involved in melting and sand casting metal with a simpler charcoal furnance.

I recommend reading Gingery's book The Charcoal Foundry.

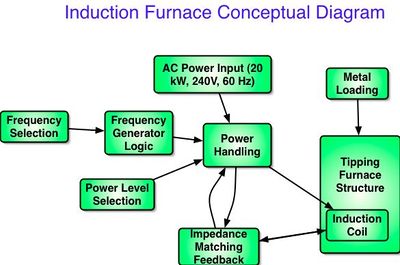

Typically the material to be melted is a solid rod, a pipe/'sleeve', or a sheet. Using these shapes makes it feasible to calculate heat transfer. I expect an initial prototype open source induction furnace should prioritize solid rods, since this volume could approximate powders and aggregate scrap. One key consideration is the power supply selection. The furnace also needs a water cooling system, especially for steel melting. The method of electromagnetic induction is similar to the function of transformers, and in fact a transformer is one component of an induction furnace, used for tuning tank circuit to frequency in the case of fixed frequency power source.

The induction furnance should be designed to be capable of melting all the steel required to cast base metal parts for the GVCS. Therefore, the selection or engineering of the power supply and water cooling system should have a backtracked dependency from all the CAD parts such that the 'time to melt' the GVCS parts is reasonable. Perhaps a month of operation is a good intitial target? This might be a significant volume of metal... Such as several metric tons. The best rough estimate I can give is 50 * 100 = 5000kg of metal (an average of 100kg per machine) and a budget of 30 days with continous 24/7 operation, that's 10000/30/24 = ~7kg to melt per hour. Before better CAD models are available, it might make sense for an intelligent being to estimate the machines and render a histogram of the estimated machine metal weights.

Design

- IGBT-based induction furnace power supply - [1]

- Category: Induction Furnace

- Induction Furnace Forum

- Induction Furnace Request for Bids

- Open Pario

Resources

- Articlesfactory: Furnace Selection

- Inductionheater.org

- Dansworkshop: Induction Heating

- Educypedia: Induction-related Articles

- Appropedia: Induction Heating

- [2] Home made induction heater

- Allaboutcircuits: Articles on Electricity and Electronics

- 1974 US Patent 3798344 Channel Type Induction Furnace (Many induction furnace patents are more than 20 years old, and therefore public domain.)

- Foundry Magazine trade rag

- Foundry Practice vendor house rag

- Furnace rebuilder

- Jim Metcalf memoir Fascinating memoir of a person deeply involved with induction heating development

- Ajax 50kW induction heater rebuild project

DIY Furnaces

- Appears to be about 10-20kW - 2021 - [3]

- Simple circuit melts a nail - [4]

- Power Labs - [5]

- http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat1.html

- 10 kW heater + inverter circuit - [6]

- http://www.richieburnett.co.uk/indheat.html

- http://www.hvguy.4hv.org/ih/

- http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat1.html

- Achieved 10 kW; Induction Furnace Kit: http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat8.html

- http://www.dansworkshop.com/electricity-and-electronics/induction-heating.htm

- Roy 1200 is an open source induction heater. Fluxeon sell a kit versions between $196.50 and $326.31 depending on whether all parts are included.

Commercial

- Across International - NJ, USA - induction heaters - [7]

- Ajax Magnethermic/Tocco [8]

- India supplier of induction furnaces - [9]

- Commercial induction furnace power supplies from Superior Induction - [10]

- EPRI works with induction - The EPRI Center for Materials Production at Carnegie Mellon, Pittsburgh, PA, 412-268-3243

- List of chinese induction furnace manufacturers

- 110kw 3.1kHz melts 110kg in 1hr. Video[11]

Forums

- Open Source Induction Furnace Forum

- CNC Zone - Induction furnace topic

- Metal Casting Zone - Furnace Info

- Metal and Metallurgy engineering Forum

- Electronics and electricity

- Electronics

Links

- Technical basics and applications of induction furnaces - excellent PDF - [12]

See Also